Photovoltaic solar cells, thin silicon disks that convert sunlight into electricity, have become a cornerstone of modern renewable energy. These versatile devices power everything from small calculators and communication systems to rooftop panels on homes and even satellites. However, the quest for more affordable and efficient solar technology is pushing the boundaries of innovation. Solar panels have evolved significantly over the past few decades, becoming more efficient and cost-effective. Among the latest advancements are ultra-thin and ultra-efficient solar cells, which promise to reshape the solar energy landscape. In this article, we explore the latest advancements in manufacturing ultra-thin and ultra-efficient solar cells and their potential impact on the energy landscape.

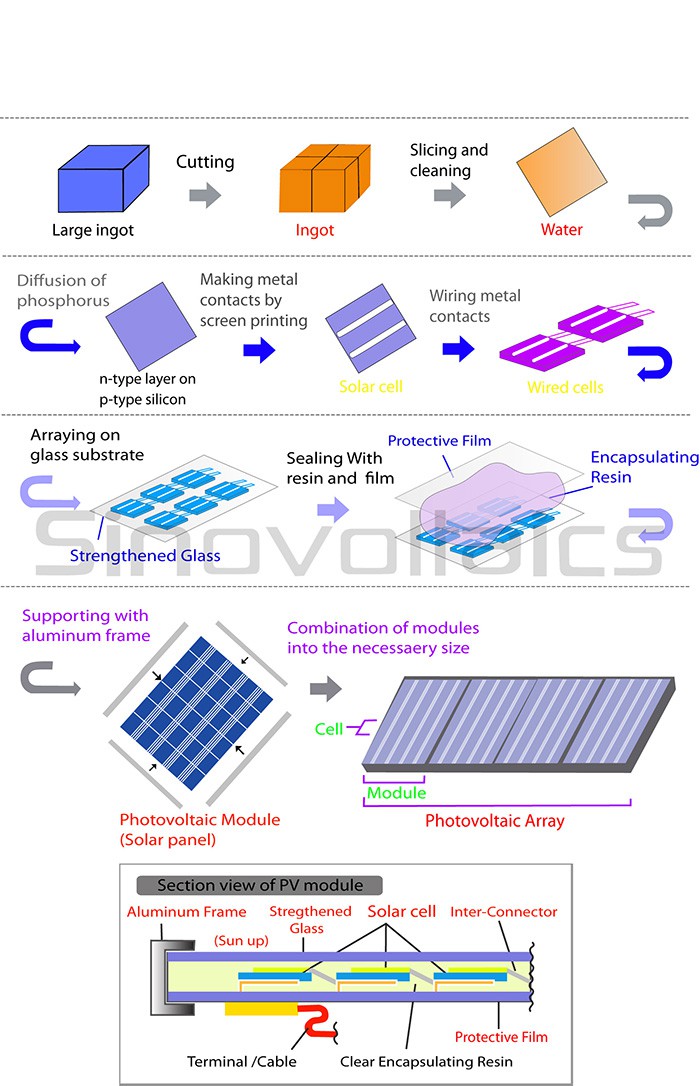

The basic component of a solar cell is pure silicon, which is not pure in its natural state. Pure silicon is derived from such silicon dioxides as quartzite gravel (the purest silica) or crushed quartz. Currently, 90 percent of the world’s solar panels are made from crystalline silicon, and the industry continues to grow at a rate of about 30 percent per year, the researchers say.

The resulting pure silicon is then doped (treated with) with phosphorous and boron to produce an excess of electrons and a deficiency of electrons respectively to make a semiconductor capable of conducting electricity. The silicon disks are shiny and require an anti-reflective coating, usually titanium dioxide.

The solar module consists of the silicon semiconductor surrounded by protective material in a metal frame. The protective material consists of an encapsulant of transparent silicon rubber or butyryl plastic (commonly used in automobile windshields) bonded around the cells, which are then embedded in ethylene vinyl acetate. A polyester film (such as mylar or tedlar) makes up the backing. A glass cover is found on terrestrial arrays, a lightweight plastic cover on satellite arrays. The electronic parts are standard and consist mostly of copper. The frame is either steel or aluminum. Silicon is used as the cement to put it all together.

There is a need for cheaper, more efficient solar cells than the traditional silicon solar cells so that more people may have access to this technology. The prices for solar panels have plummeted over the past few years, so continuing to focus on making them less expensive would have little impact on the overall cost of a solar power system; expenses related to things like wiring, land, permitting, and labor now make up the vast majority of that cost. Making modules more efficient would mean that fewer panels would be needed to produce the same amount of power, so the costs of hardware and installation could be greatly reduced.

1. The Quest for Ultra-Thin Solar Cells

Ultra-thin solar cells represent a major breakthrough in solar technology. Unlike traditional solar panels that use thick silicon wafers, ultra-thin cells are made from much thinner materials—sometimes just a few micrometers thick. This reduction in thickness offers several benefits:

- Reduced Material Costs: Less material means lower production costs and reduced environmental impact. Reducing the thickness of silicon cells can significantly cut production costs. With less material required, the cost of each panel drops, making solar energy more accessible.

- Flexibility and Versatility: Thinner cells are lightweight and flexible, allowing for integration into various surfaces and products, including flexible and wearable electronics.

- Improved Efficiency: Advances in material science and design allow these cells to capture more sunlight and convert it into electricity more efficiently.

Reserachers have been developing new architectures , techniques, materials including nanomaterials, stacking multiple layers , developing hybrid technologies and manufacturing processes to enhance the efficnecy and also reduce the cost of solar cells.

The Rise of Thin-Film Technologies

Traditional solar panels are made of silicon wafers, which can be bulky and heavy. Thin-film solar cells, on the other hand, are a game-changer. These next-generation cells are made from a variety of materials like perovskites, copper indium gallium selenide (CIGS), and cadmium telluride (CdTe). These materials can be deposited in thin layers on flexible substrates, making them:

The Promise of Thin Silicon Cells

Thin silicon cells were explored over a decade ago, during a period of high silicon prices due to supply shortages. At that time, the approach faced significant hurdles: thin silicon wafers were brittle and fragile, leading to high manufacturing losses, and their efficiency was lower than thicker alternatives. Today, advancements in handling equipment and solar cell architecture are beginning to address these issues.

A study published in the journal Energy and Environmental Science, co-authored by MIT postdoc Zhe Liu, Professor Tonio Buonassisi, and their colleagues at MIT and NREL, presents a new “technoeconomic” approach. This approach emphasizes that economic considerations are now as crucial as technological innovations for improving solar panel affordability.

Reducing Thickness for Cost and Efficiency Benefits

Currently, crystalline silicon accounts for 90% of the world’s solar panels, with the industry expanding at about 30% annually. Traditional silicon photovoltaic cells are made from wafers that are 160 micrometers thick. The researchers suggest that by improving handling methods, the thickness could be reduced to 100 micrometers, and eventually to as little as 40 micrometers or less. This reduction would require only a quarter of the silicon for the same panel size, potentially lowering both material costs and manufacturing complexity.

Thinner wafers could also alleviate manufacturing bottlenecks. The production of silicon crystal ingots, which are then sliced into wafers, is capital-intensive and time-consuming. By reducing wafer thickness, the demand for ingot production could decrease, facilitating faster expansion of solar panel manufacturing.

Examining Efficiency and Implementation Challenges

The study explored various solar cell architectures, including advanced technologies like PERC (passivated emitter and rear contact) cells, to assess their performance at different thicknesses. The researchers found that efficiency remains relatively stable down to 40 micrometers with current manufacturing processes. This “efficiency plateau” indicates that significant cost savings can be achieved without a substantial loss in performance.

Transitioning to thinner wafers will involve significant adjustments to existing manufacturing facilities. While the initial investment and development of new equipment and procedures will be costly and time-consuming, the long-term benefits could outweigh these costs. With current technology, achieving a wafer thickness of 100 micrometers should be feasible, and further reductions to 15 micrometers might be possible with advances in detection and new wafer growth techniques.

The Road Ahead

Despite recent declines in silicon prices, the potential for cost reductions through thinner silicon remains substantial. As solar cell efficiency improvements are limited, optimizing thickness could be the key to further advancements. The study aims to provide a roadmap for expanding solar manufacturing technologies, encouraging industry stakeholders to collaborate on developing and implementing new standards and practices.

Expert Opinions

Andre Augusto, an associate research scientist at Arizona State University, highlights that refining silicon and wafer manufacturing is the most capital-intensive part of solar panel production. Thinner wafers could alleviate some of the cost pressures associated with rapid industry expansion, as they allow for more wafers per machine without significantly increasing capital expenses. He also notes that thinner wafers may perform better in certain climates, particularly in warmer conditions.

Renewable energy analyst Gregory Wilson emphasizes the significant impact of reducing silicon usage in mainstream cells. He points out that this reduction would not only lower capital costs but also decrease the energy required for silicon production. Major PV cell manufacturers are likely to adopt these innovations once they see clear economic benefits, making research from institutions like MIT crucial for guiding industry shifts.

The study underscores that while the path to thinner silicon cells is fraught with challenges, the potential benefits are substantial. By making this transition, the solar industry could achieve significant cost reductions and accelerate the shift toward more affordable and widespread solar energy solutions.

Manufacturing Processes for Ultra-Thin Solar Cells

- Chemical Vapor Deposition (CVD):

- CVD is a widely used method for creating thin films of material on a substrate. In solar cell production, it involves depositing layers of semiconductor materials onto a base, forming the ultra-thin layer of the solar cell.

- This process allows for precise control over the thickness and composition of the layers, leading to improved efficiency and performance.

- Atomic Layer Deposition (ALD):

- ALD is a technique that deposits ultra-thin layers of material one atomic layer at a time. This method is ideal for creating high-quality, uniform thin films with excellent control over thickness.

- ALD is particularly useful for manufacturing advanced materials like perovskite, which is gaining attention for its potential in ultra-thin solar cells.

- Printing Techniques:

- Techniques like inkjet printing and roll-to-roll printing are used to apply thin layers of photovoltaic materials onto flexible substrates.

- These methods are cost-effective and scalable, making them suitable for mass production of ultra-thin solar cells.

2. Achieving Ultra-Efficiency in Solar Cells

While reducing thickness is crucial, achieving high efficiency is equally important. Ultra-efficient solar cells convert a higher percentage of sunlight into electricity. The following technologies and processes are driving this advancement:

- Perovskite Solar Cells: Perovskite solar cells are a particularly exciting development. These cells have demonstrated remarkable efficiency gains in recent years, exceeding 30% efficiency in lab settings. This is significantly higher than the efficiency of traditional silicon cells, which typically hover around 20-22%.

- Perovskite materials have emerged as a game-changer in solar technology due to their high efficiency and low production costs.

- The manufacturing process involves layering perovskite materials onto a substrate, often using techniques like spin-coating or vapor deposition.

- Perovskite cells have achieved efficiencies exceeding 25%, competing with traditional silicon-based cells.

- Multi-Junction Solar Cells:

- Multi-junction cells use multiple layers of different semiconductor materials to capture a broader spectrum of sunlight.

- Each layer is tuned to absorb specific wavelengths, resulting in higher overall efficiencywith some cells reaching up to 40% efficiency under concentrated light. These cells are often manufactured using complex deposition techniques and require precise alignment of the layers.

- Quantum Dot Solar Cells:

- Quantum dots are nanometer-sized semiconductor particles that can be engineered to absorb specific wavelengths of light.

- These cells use quantum dots to enhance light absorption and increase efficiency. The manufacturing process involves synthesizing and depositing quantum dots onto a substrate, often using techniques like colloidal synthesis.

3. The Impact and Future of Ultra-Thin and Ultra-Efficient Solar Cells

The advancements in ultra-thin and ultra-efficient solar cells hold great promise for the future of solar energy:

- Cost Reduction: Lower material and manufacturing costs will make solar power more accessible and affordable.

- Wider Applications: The flexibility of ultra-thin cells opens up new possibilities for integration into various products and surfaces.

- Higher Efficiency: Enhanced efficiency means more energy production from the same amount of sunlight, improving the overall effectiveness of solar power.

As research and development continue, we can expect further innovations in manufacturing processes and materials, driving down costs and increasing performance. The future of solar energy looks brighter than ever, with ultra-thin and ultra-efficient solar cells leading the way in creating a more sustainable and energy-efficient world.

4. Notable Advances in Solar Cell Technology

Thinner Silicon Cells: Researchers at MIT and the National Renewable Energy Laboratory (NREL) are exploring the benefits of thinner silicon wafers. By reducing the thickness from 160 micrometers to as low as 40 micrometers, they aim to cut costs and expand manufacturing capacity. Improvements in handling and cell architecture are making this possible.

III-V Solar Cells: Russian researchers at ITMO University have developed a new manufacturing process for III-V solar cells using A3B5 semiconductors on silicon substrates. This technique could enable cells with efficiencies around 40%, while leveraging the less expensive silicon substrate. The process of integrating A3B5 semiconductors with silicon is complex due to the need for precise alignment of crystal lattice parameters. The team has overcome this challenge by using gallium phosphide (GaP), which, when combined with nitrogen, offers improved light-trapping capabilities and can be effectively integrated onto silicon. This method not only enhances the efficiency of the solar cells but also allows silicon to act as an additional photo-active layer, absorbing infrared light. Similar developments in solar cell manufacturing techniques, such as those reported by Chinese researchers in 2018, further underscore the growing potential for innovation in the solar energy sector.

Shin-Etsu Chemical Co., Ltd. has successfully established a mass production process for its advanced monocrystalline silicon solar cells, achieving an industry-leading conversion efficiency of 21%. The new manufacturing process, which builds on existing screen-printing technology, can be integrated with minimal adjustments to existing systems. Shin-Etsu Chemical holds 10 patents related to this technology and has begun licensing its solar cell manufacturing methods. The company’s solar panel modules, designed with bifacial light-receiving cells, maintain high performance even in challenging conditions such as snow or sand accumulation, thanks to their ability to generate increased power from reflected light.

Ultra-Thin Silver Films: Researchers at Ruhr-Universität Bochum and the University of Wuppertal have created ultra-thin silver films with high purity and electrical conductivity. This advancement promises to enhance the efficiency of solar cells and light-emitting diodes. Traditional methods struggled with producing pure, ultra-thin silver films due to the sensitivity of precursors to air and light, which often led to contamination. However, the new synthesis technique, developed by Professor Anjana Devi and Nils Boysen, uses a silver precursor stabilized by amide and carbene without the need for fluorine, phosphorus, or oxygen. This method enables the deposition of a few-atom-thick, transparent, and electrically conductive silver film onto electrodes via atomic layer deposition. The process operates at atmospheric pressure and low temperatures, making it conducive to industrial-scale production and setting the stage for advanced, highly efficient solar cells and lighting technologies.

Flexible Organic Solar Cells: A team from King Abdullah University of Science & Technology (KAUST) has developed solar panels so thin and flexible they can rest on a soap bubble. Using inkjet printing, they achieved power conversion efficiencies of up to 4.73% on rigid substrates and 3.6% on flexible ones. The researchers employed a highly conductive polymer, PEDOT, and a light-capturing material to construct the panels, which are then sealed with a protective, flexible parylene coating. The breakthrough represents a significant advancement for creating versatile, lightweight solar cells suitable for diverse applications, including wearable and medical devices.

5. Challenges and Considerations

While the future of ultra-thin and ultra-efficient solar cells looks bright, there are still challenges to overcome:

- Durability: Some thin-film technologies, like perovskites, can be less stable than silicon under harsh environmental conditions. Research is ongoing to improve their long-term performance.

- Scalability: Moving from lab-scale production to large-scale manufacturing requires further development and cost reduction.

- Environmental Impact: The materials used in some thin-film technologies, like CdTe, raise concerns about potential environmental impact during production and disposal.

6. The Path Forward

The continued evolution of solar cell technology is crucial for addressing global energy needs. Advances in manufacturing processes and materials are making solar energy more affordable and efficient, paving the way for widespread adoption.

As research and development progress, these next-generation technologies have the potential to:

- Increase Solar Energy Adoption: By making solar panels more versatile and potentially cheaper, these cells can revolutionize how we capture and utilize solar power.

- Power a Wider Range of Applications: Imagine powering your everyday devices from your laptop to your electric car with integrated thin-film solar cells.

- Create a More Sustainable Future: By making solar energy more accessible and efficient, we can move towards a cleaner and more sustainable energy future.

Perovskite solar cells remain the star attraction. Researchers have made significant strides in addressing their stability concerns:

- Improved Material Composition: New formulations are being developed that are more resistant to degradation from heat, moisture, and UV light. This enhances their long-term performance and viability for real-world applications.

- Surface Passivation Techniques: Coating perovskite cells with protective layers minimizes defects and recombination losses, leading to improved efficiency and lifespan. Recent breakthroughs have achieved passivation techniques that maintain high efficiency for over 1,000 hours under harsh conditions.

Efficiency Records Shattered:

The quest for ever-increasing efficiency continues to bear fruit. Labs have reported perovskite solar cells exceeding a remarkable 33% efficiency in converting sunlight into electricity. This shatters previous records and brings perovskite technology closer to competing with the efficiency of traditional silicon cells.

Beyond Perovskites: Exploring New Frontiers

While perovskites are a major focus, research into other thin-film materials is also yielding promising results:

- Tandem Cell Technology: Stacking different types of thin-film cells can create “tandem” solar cells that capture a wider range of sunlight wavelengths, further boosting efficiency. Recent advancements have demonstrated tandem cells exceeding 35% efficiency.

- Organic Solar Cells: These lightweight and flexible cells made from organic materials are actively being developed for applications like roll-up solar panels or integration into fabrics.

A Brighter Solar Future Beckons

Despite the hurdles, the future of solar energy shines brightly. As research and development continue, ultra-thin and ultra-efficient solar cells promise to:

- Revolutionize Solar Panel Design: These advancements will lead to lighter, more versatile solar panels that can be integrated into various applications, from building materials to portable devices.

- Reduce Energy Costs: Increased efficiency and potentially lower production costs can make solar energy a more competitive and attractive option for consumers and businesses.

- Accelerate Sustainable Energy Transition: By making solar energy more accessible and efficient, we can move towards a cleaner and more sustainable future at a faster pace.

Economic and Environmental Impact:

- Reducing the thickness of solar cells and enhancing their efficiency can lower costs and increase the feasibility of solar energy projects.

- Innovations like flexible and ultra-thin solar panels open up new possibilities for integration into various applications, from consumer electronics to large-scale power generation.

As researchers and manufacturers push the boundaries of solar technology, the future of solar energy looks promising. The advancements in ultra-thin and ultra-efficient solar cells are setting the stage for a more sustainable and energy-efficient world.

References and Resources also include:

http://www.mining.com/silver-becomes-key-component-ultra-efficient-solar-cells/

https://www.sciencedaily.com/releases/2020/01/200128114722.htm

https://www.advancedsciencenews.com/breakthrough-in-wireless-technology-with-ultrathin-solar-panels/