Digital Twins: The New Frontier of Military Innovation and Operational Excellence

Discover how digital twin technology is transforming military readiness, predictive maintenance, and autonomous warfare, redefining the future of defense strategy.

Introduction

In an era where technology drives efficiency and innovation, Digital Twins have emerged as a game-changing concept across industries—from manufacturing and healthcare to aerospace and defense. By creating virtual replicas of physical assets, processes, or systems, digital twins enable real-time monitoring, predictive analytics, and enhanced decision-making.

For the military, digital twins are not just a technological advancement—they are a force multiplier, improving readiness, reducing downtime, and optimizing mission success. By creating virtual, real-time replicas of physical assets—from individual fighter jets and naval warships to entire supply chains and military bases—digital twins are fundamentally changing how armed forces approach innovation, equipment maintenance, and mission preparation. These sophisticated virtual models enable predictive maintenance capabilities, accelerate research and development cycles, and enhance battlefield decision-making processes. This article examines how military forces worldwide are harnessing the power of digital twins to boost innovation, improve operational reliability, and ensure constant mission readiness in an increasingly complex global security environment.

What Are Digital Twins?

A digital twin is a dynamic, AI-powered virtual model that precisely mirrors a physical system, process, or asset in real time. This virtual model of a physical entity dynamically ingests data from its real-world counterpart to mirror its structure, context, and behavior throughout its lifecycle. These models continuously evolve, learning from operational data to predict failures, optimize performance, and support decision-making.

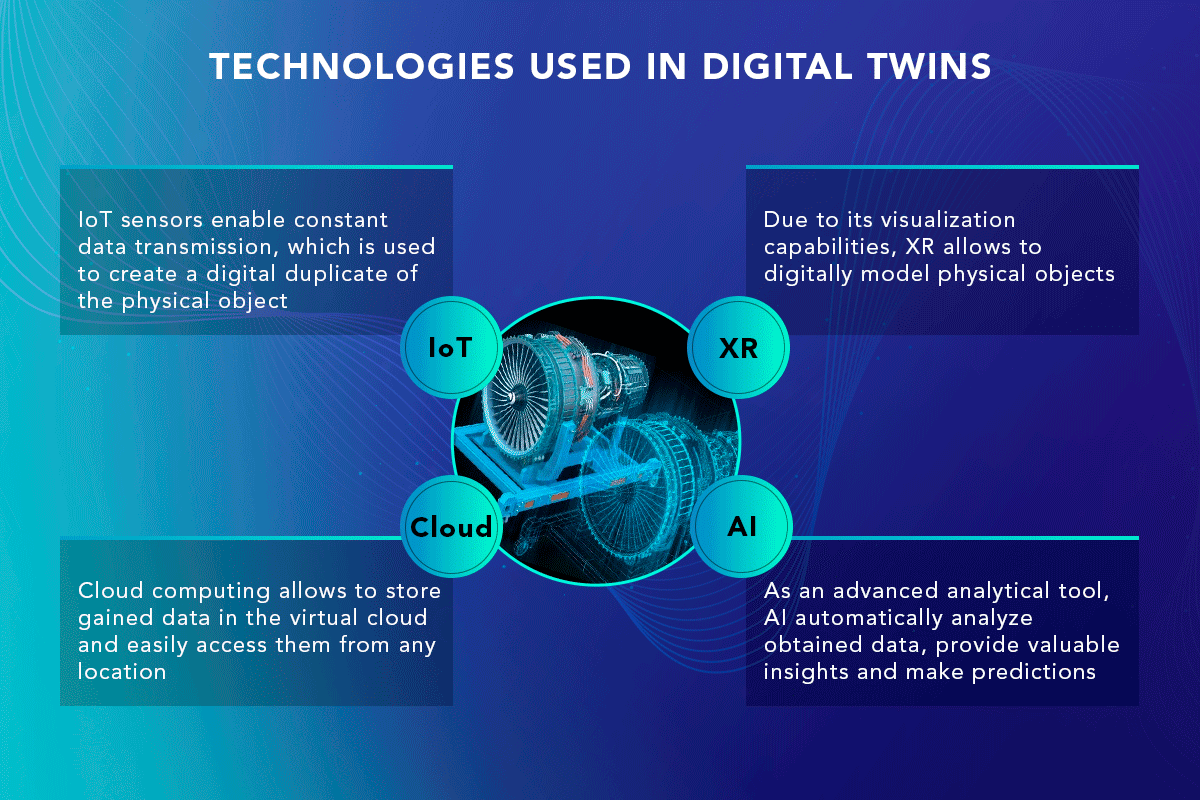

This advanced technology integrates multiple cutting-edge components including IoT sensors, machine learning algorithms, and high-fidelity simulations to provide unprecedented insights into equipment performance, wear patterns, and operational efficiency.

Key capabilities include real‑time monitoring, what‑if analysis, and closed‑loop optimization, allowing stakeholders to anticipate issues, test design changes, and improve operational efficiency without disrupting live systems

Key Components and technologies of Digital Twins

The foundation of an effective digital twin system rests on four essential elements. First, the physical asset serves as the real-world counterpart being replicated—this could range from a helicopter or naval vessel to an entire missile defense system. Second, the virtual model acts as the high-fidelity digital representation that continuously evolves through real-time data inputs.

Third, data connectivity ensures a seamless flow of real-time information between the physical and digital versions, enabling continuous updates and adjustments. Finally, sophisticated AI and analytics platforms process this constant stream of data to forecast potential failures, optimize performance parameters, and simulate countless operational scenarios before they occur in the physical world.

By integrating real-time data, advanced analytics, and simulation, digital twins enable organizations to iterate designs rapidly, predict failures before they occur, and conduct realistic training and mission rehearsal in virtual environments. In the defense sector, these capabilities translate into more agile procurement, optimized maintenance cycles, and enhanced preparedness through immersive war-gaming of complex scenarios. Collectively, digital twins are reshaping how enterprises and military forces manage lifecycles, respond to threats, and maintain a competitive edge in an increasingly interconnected and contested domain.

For in-depth understanding on Digital Twins technology and applications please visit: Building a Better World with Digital Twins: An Introduction to the Technology and its Applications

Extended Reality (XR) is a visualization technology that allows for the creation of digital representations of physical objects. XR capabilities empower digital twins to digitally model real-world objects, enabling users to interact with virtual content. Multiphysics modeling tools are employed to collect data and create mathematical representations of systems and components.

Designing digital twins with virtual reality (VR) capabilities enhances the design process by providing immersive views and natural interaction. VR simulations can be run in real-time, enabling designers to observe the product’s behavior and appearance before production. This facilitates rapid-paced design iterations. Moreover, in scenarios such as remote surgeries, VR-enabled digital twins can be coupled with robotics, allowing surgeons to perform operations based on the virtual representation of a patient’s organ.

Cloud computing technology plays a crucial role in digital twin applications by providing efficient storage and accessibility of large volumes of data over the internet. Storing data in the virtual cloud enables easy access from any location, facilitating data management and analysis.

Accelerating Military Innovation

Rapid Prototyping & Virtual Testing

Traditional defense research and development has long relied on costly, time-consuming physical prototyping processes. Digital twins are revolutionizing this approach by eliminating much of the guesswork through advanced simulation capabilities. Engineers can now simulate new aircraft designs under extreme combat conditions, test next-generation weapon systems in virtual battlefield environments, and refine autonomous drone swarm tactics through AI-driven modeling—all before committing to physical production.

A prime example of this innovation acceleration can be seen in the U.S. Air Force’s ET-7 Red Hawk jet trainer program. By leveraging digital twin technology throughout the design process, the Air Force achieved an 80% reduction in development time compared to traditional aircraft design methods. Companies like Rolls‑Royce and Siemens deploy twins of engines and production lines to evaluate design tweaks and production processes before physical implementation, cutting time‑to‑market by up to 50%

AI-Driven Design Optimization

Digital twins enable defense engineers to analyze millions of data points to optimize designs before manufacturing begins. This capability allows for the identification of structural weaknesses in airframes, the optimization of fuel efficiency in next-generation fighter jets, and the enhancement of stealth capabilities through advanced material science simulations. AI-driven twins can autonomously propose improvements, simulate complex interactions, and enable personalized configurations, fostering “breakthrough innovations rather than incremental changes” in R&D

Rolls-Royce provides an excellent case study in this application, using digital twins to thoroughly test jet engine performance under extreme operational scenarios. This approach has led to measurable improvements in engine durability while significantly reducing in-service failures.

Supply Chain Resilience

By modeling end‑to‑end supply networks, digital twins help firms stress‑test logistics under various disruptions—such as natural disasters or geopolitical events—and implement mitigation strategies that ensure continuity and reduce costs

Enhancing Military Reliability

Predictive Maintenance

Digital twins are transforming military maintenance operations from reactive repair processes to proactive, predictive systems. By continuously monitoring critical parameters like engine vibrations, structural corrosion, and mechanical stress in real time, these virtual models can alert maintenance crews to potential issues long before they result in operational failures. Early adopters of this technology are reporting reductions in unscheduled downtime by up to 50%.

The U.S. Army’s UH-60 Black Hawk helicopter program demonstrates the power of this application. Through comprehensive 3D scanning of aging airframes and components, the Army is using digital twins to facilitate on-demand manufacturing of obsolete parts, effectively extending the service life of these critical aircraft.

Real-Time Fleet Health Monitoring

Naval and aviation units worldwide are implementing digital twin technology to maintain constant awareness of their equipment’s operational status. These systems track wear patterns on ship hulls, monitor stress fatigue in aircraft fuselages, and optimize maintenance schedules based on actual usage data rather than conservative time-based estimates.

The U.S. Navy’s Shipyard Infrastructure Optimization Program (SIOP) showcases this application at scale. By creating digital twins of century-old dry dock facilities, the Navy has achieved 30% improvements in maintenance efficiency while modernizing critical naval infrastructure.

Optimization of Maintenance Schedules

Real‑world sensor feeds into twins allow maintenance activities to be scheduled based on actual condition rather than fixed intervals, reducing downtime by up to 30% and cutting maintenance costs by 10–20%. Booz Allen’s Digital Twin for a major DoD installation integrates live sensor data to streamline operations and maintenance, improving asset visibility and reducing logistic footprints using AR/VR interfaces for field technicians

Revolutionizing Military Readiness

Military readiness encompasses the preparedness, agility, and effectiveness of armed forces to fulfill their missions and respond to emerging threats. Digital twins have the potential to revolutionize military readiness by providing real-time situational awareness, training simulations, and mission planning capabilities.

Digital twin models can integrate data from various sensors, intelligence sources, and simulations, creating a comprehensive operational picture for military commanders. This enhances situational awareness, allowing decision-makers to make timely and informed choices. Furthermore, digital twins enable the creation of virtual training environments, where soldiers can simulate complex scenarios and practice their skills in a risk-free setting. These training simulations can replicate real-world conditions, improving readiness and reducing training costs.

Digital twins revolutionize military readiness by providing immersive training, mission planning, and wargaming capabilities. Virtual battlefield twins enable commanders to rehearse joint operations, test force deployments against digital adversaries, and refine tactics in a repeatable environment. NATO’s Human Digital Twin initiative extends this concept to personnel readiness by simulating cognitive and stress responses in virtual war‑games, enhancing decision‑making under pressure and accelerating indoctrination into new doctrines.

Moreover, the U.S. Space Force employs space‑based digital twins for satellite constellation management, enabling real‑time monitoring of orbital assets, anomaly resolution, and agility in contested environments

War‑gaming and Mission Rehearsal

Defense organizations employ digital twins of battlefields, weapon systems, and even adversary assets to conduct realistic simulations. NATO’s Human Digital Twin initiative uses virtual soldiers to refine tactics, test equipment compatibility, and improve decision‑making under stress

Hyper-Realistic Training Simulations

Digital twins are enabling a new generation of immersive, AI-driven training environments where military personnel can prepare for real-world operations without the associated risks. Soldiers can now train in virtual replicas of actual enemy terrain, practice complex drone swarm tactics against adaptive AI opponents, and refine electronic warfare strategies in simulated jamming environments that precisely mimic real combat conditions.

The U.S. Space Force is leveraging digital twins to train Guardians on satellite operations and cyber‑electromagnetic activities, ensuring new technologies are integrated seamlessly and personnel readiness stays high

The Air Force’s innovative “Colosseum” program takes this concept even further by pitting digital twin representations of various weapons systems against each other in virtual combat scenarios. This approach allows for thorough evaluation and refinement of new designs before committing to physical production.

Mission Planning & Decision Superiority

Military commanders are increasingly relying on digital twins to enhance operational planning and execution. These systems can simulate countless battlefield logistics scenarios, test supply chain resilience against potential cyberattacks, and optimize troop deployments using real-time data feeds from satellites, drones, and ground sensors.

The Navy’s PMA-234 program provides a compelling example of these capabilities in action. By employing digital twins to troubleshoot complex ALQ-99 tactical jamming systems, maintenance crews have achieved 40% reductions in critical repair timelines.

Accelerated Acquisition and Lifecycle Management

By simulating the full lifecycle of complex systems—such as the F‑35 fighter jet—the DoD can rapidly evaluate design changes, predict logistic needs, and optimize fleet availability, resulting in “quicker innovation, optimized performance, and improved supply chain resilience”

Autonomous Systems & AI-Driven Warfare

Unmanned systems, such as drones and robotic vehicles, rely on digital twins for autonomous decision-making. These virtual models process real-time data to navigate, assess threats, and execute missions with minimal human intervention. By enhancing situational awareness and reducing human risk, digital twins are paving the way for the next generation of AI-driven warfare.

Challenges & The Road Ahead

Despite their tremendous potential, military organizations must overcome several significant challenges in digital twin implementation.

While digital twins offer immense potential, several challenges must be addressed to fully realize their benefits. Moreover, the computational demands of real‑time simulation and the complexity of integrating multi‑source data pose engineering challenges. However, ongoing advances in cloud computing, edge analytics, and AI are rapidly lowering these barriers.

Data security remains a top concern, as sensitive military information must be protected from cyber threats. Cybersecurity remains a paramount concern, as these systems create new vulnerabilities that adversaries may attempt to exploit.

Integration complexity also poses a hurdle, particularly when merging legacy systems with cutting-edge digital twin platforms, often requiring extensive retrofitting with modern IoT sensors. Additionally, scalability issues may arise when expanding digital twin applications across entire fleets or military bases. Additionally, the high initial costs of large-scale adoption require careful cost-benefit analysis to justify the investment.

Looking to the future, digital twin technology promises to enable even more advanced capabilities. AI-powered autonomous warfare systems, such as intelligent drone swarms guided by digital twin networks, are already in development. Fully digitalized supply chains with real-time global logistics tracking are becoming operational realities. Perhaps most transformative will be the development of “living” battle simulations that continuously adapt based on real-world intelligence feeds.

Conclusion: The Digital Battlefield of Tomorrow

Digital twins have firmly transitioned from science fiction concepts to essential components of modern military strategy. From predictive maintenance systems that prevent equipment failures to AI-driven mission planning tools that optimize battlefield decisions, this technology is ensuring that armed forces remain agile, efficient, and perpetually prepared for emerging threats.

As defense budgets face increasing scrutiny and global security challenges grow more complex, digital twins offer a cost-effective, high-impact solution for maintaining operational superiority. By transforming raw data into actionable battlefield intelligence, these systems are redefining what it means to be mission-ready in the 21st century

References and Resources also include:

https://www.avm-mag.com/army-using-digital-twins-to-breathe-new-life-into-aging-helicopter-fleet/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis