In the realm of advanced materials, breakthroughs often emerge not from discovering new elements, but from ingeniously combining existing ones at scales previously deemed unattainable. Nanocomposite Optical Ceramics (NCOCs) exemplify this innovation. Through meticulous engineering, researchers have developed a material that merges the clarity of crystals with the toughness of ceramics, poised to redefine infrared optics for applications ranging from hypersonic missile domes to high-energy laser systems.

For decades, single-crystal materials like sapphire have set the standard for high-performance infrared windows and domes. Their primary advantage lies in optical transparency; the absence of grain boundaries allows them to transmit infrared light efficiently across critical bands such as the 3–5 micrometer mid-wave infrared (MWIR) and 8–12 micrometer long-wave infrared (LWIR) regions. However, sapphire and similar crystals are brittle, expensive, and challenging to shape into complex geometries, making them less suited to the extreme demands of hypersonic flight or battlefield conditions.

Raytheon and the Birth of NCOC

Raytheon’s Advanced Technology team, in collaboration with the Defense Advanced Research Projects Agency (DARPA) and other partners, has been at the forefront of developing next-generation optical materials essential for military surveillance and targeting operations. Their work led to the discovery of NCOC, a nanocomposite material that combines two infrared-transparent ceramics into nanosized grains. Unlike single crystals such as sapphire, which have no grain boundaries, NCOC’s structure exploits the interface between nanograins to create a material stronger than either constituent ceramic.

This design delivers outstanding performance across multiple fronts. NCOC exhibits excellent infrared transmission, thermal stability under extreme heat, and mechanical durability under high-velocity impact or erosion. Furthermore, unlike single crystals, it can be easily processed into complex, near-net shapes to meet specific design needs. This flexibility allows engineers to produce conformal surfaces, such as missile domes with optimized aerodynamics, reducing drag and improving overall system performance.

To further enhance operational durability, Raytheon developed a specialized protective coating for NCOC, shielding it from sand, rain, and other erosive elements. The combination of nanocomposite engineering and surface protection has enabled NCOC’s insertion into an existing missile program, with plans to expand its use across other defense systems.

The Power of the Nano-Grain

The exceptional performance of NCOC stems from its carefully engineered nanoscale grain structure. Unlike conventional ceramics, which typically contain micrometer-sized grains that scatter light and create weak points where cracks can propagate, NCOC features grains measuring only 20–100 nanometers—thousands of times smaller than the width of a human hair. These tiny grains transform potential weaknesses into strengths, as the numerous grain boundaries effectively arrest crack propagation, resulting in a fracture toughness two to three times higher than sapphire.

From an optical perspective, the nanograins significantly reduce light scattering, enabling NCOC to achieve transmission above 80–90% across the mid-wave (MWIR) and long-wave infrared (LWIR) bands. Thermally, the composite structure distributes stress more evenly and minimizes expansion mismatch, allowing the material to maintain both structural integrity and optical clarity even under the extreme heat encountered during hypersonic flight or other high-temperature environments.

By simultaneously enhancing mechanical resilience, optical transparency, and thermal stability, the nanoscale engineering of NCOC provides a combination of properties that was previously unattainable in conventional infrared ceramics.

Manufacturing Advantages and Technical Innovation

Beyond its superior performance, NCOC represents a true revolution in manufacturing advanced infrared optics. Traditional single-crystal materials like sapphire require slow, high-temperature growth processes and are extremely challenging to shape into complex geometries. In contrast, NCOC can be fabricated using powder-based ceramic processing techniques, which start with milling nanoscale ceramic powders, pressing them into a “green” body, and sintering through methods such as hot pressing, spark plasma sintering (SPS), or hot isostatic pressing (HIP).

These processes allow NCOC to be formed into near-net-shape components, including large optical windows, asymmetrical missile domes, and intricate sensor covers, all with significantly lower production costs compared to single crystals. The ability to produce complex shapes without sacrificing optical or mechanical performance gives engineers unprecedented design flexibility.

The combination of manufacturability and performance enables optimization of aerodynamics, sensor functionality, and structural resilience in ways previously unattainable with conventional materials. By bridging the gap between high performance and practical manufacturability, NCOC sets a new standard for next-generation infrared optics and defense systems.

Comparisons with Other Advanced Infrared Ceramics

To appreciate the significance of Nanocomposite Optical Ceramics (NCOC), it is helpful to examine how it compares with other leading infrared-transparent materials. Spinel, or magnesium aluminate, has long been valued for its combination of optical transparency in the mid-wave (MWIR) and long-wave infrared (LWIR) bands and its inherent hardness. However, despite these advantages, spinel can develop microcracks under extreme thermal or mechanical stress, limiting its durability in high-velocity or high-temperature applications.

ALON (aluminum oxynitride) offers remarkable hardness and impact resistance, making it highly effective at withstanding abrasive and ballistic environments. Yet ALON presents its own challenges: it is difficult to shape into complex geometries, and the high-temperature sintering processes required to produce large, curved components make it expensive and time-consuming to manufacture. Similarly, YAG (yttrium aluminum garnet) provides excellent optical clarity, particularly in the mid-infrared range, but remains brittle and is impractical for large-scale or conformal shapes needed in advanced defense systems.

NCOC bridges the limitations of these materials by combining the optical clarity of sapphire and YAG with the toughness and impact resistance approaching that of ALON. Its nanoscale grain structure minimizes light scattering while simultaneously arresting cracks, enabling superior mechanical resilience. Furthermore, NCOC can be produced using powder-based processing methods, allowing near-net-shape fabrication of complex, conformal geometries. Spanning the critical 3–12 micrometer infrared spectrum, NCOC delivers a combination of performance, durability, and manufacturability that makes it uniquely suited for modern military and aerospace applications.

Applications: From the Battlefield to Beyond

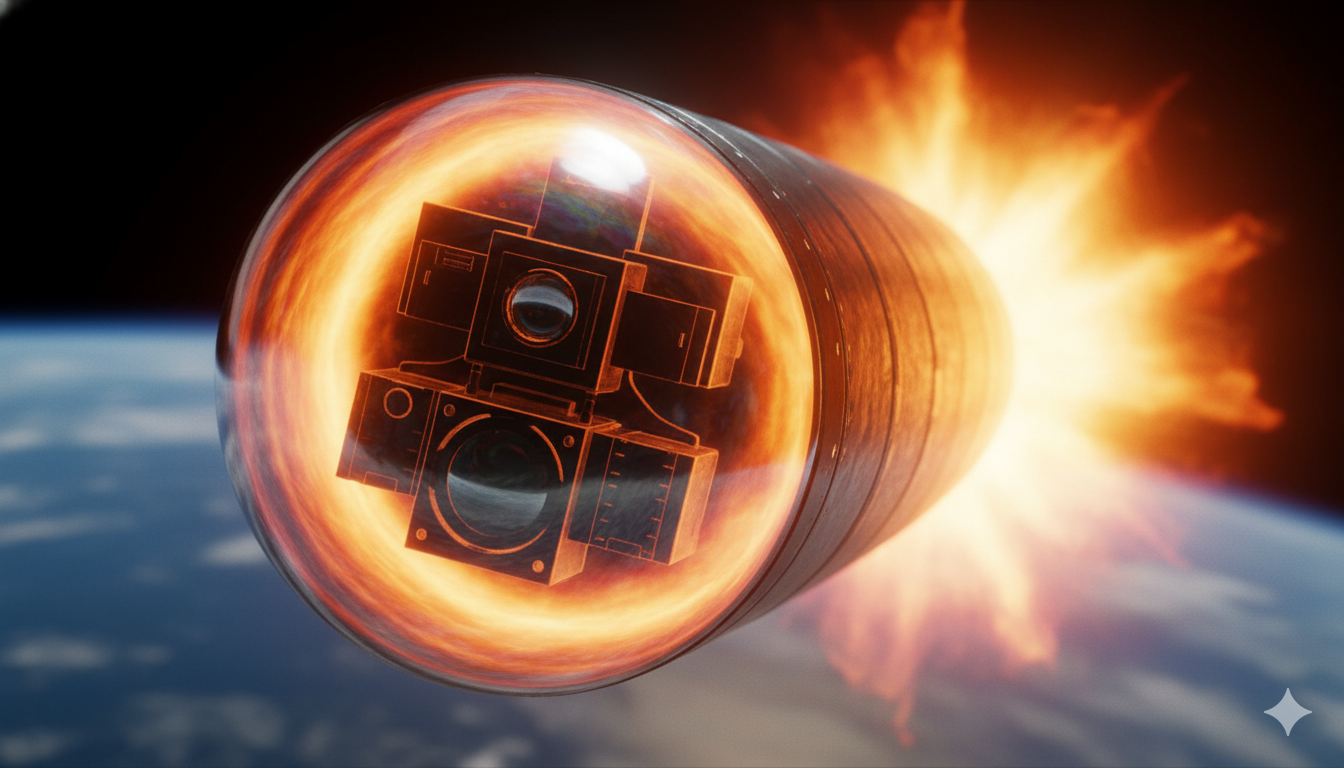

The unique combination of optical clarity, mechanical strength, and thermal resilience makes NCOC a transformative material across defense, aerospace, and industrial applications. In hypersonic missile systems, NCOC can withstand extreme aerodynamic heating and high-velocity particle erosion while maintaining efficient transmission of infrared signals for guidance and targeting. This ensures that missile seekers operate reliably even under the intense conditions of Mach 5+ flight.

Airborne and space-based intelligence, surveillance, and reconnaissance (ISR) platforms also benefit from NCOC’s durability. Its resistance to sand, rain, debris, and other environmental hazards ensures persistent, high-quality imaging, providing a tactical advantage in challenging operational theaters. Similarly, high-energy laser systems gain protection from the material’s thermal stability, which prevents distortion or degradation of sensitive optical beams under extreme heat loads.

Beyond defense, NCOC has a growing role in industrial and scientific environments where durability and infrared transparency are critical. It can protect sensors and optical instruments in high-temperature furnaces, chemical processing plants, and deep-sea exploration vehicles, enabling reliable monitoring and precise measurements under conditions that would challenge conventional optical materials. Its versatility demonstrates the broad potential of NCOC as a next-generation solution for both military and civilian applications.

Innovation Through R&D and Collaboration

Although NCOC was initially developed to meet the requirements of a specific missile program, its creation underscores a broader truth: innovation in advanced materials depends on anticipating future operational needs. Engineers and scientists must identify the properties that tomorrow’s technologies will demand, often investing years in research for systems that do not yet exist. Achieving this requires sustained R&D, interdisciplinary collaboration, and vertical integration—linking fundamental research, computational modeling, AI-assisted design, and prototyping—to ensure that laboratory discoveries can be translated into practical, deployable solutions.

Artificial intelligence and machine learning have become increasingly critical to this process. They enable high-fidelity simulations, provide predictive insights into material behavior under extreme conditions, and help optimize manufacturing processes at scale. By leveraging these tools, research teams can accelerate the development cycle, reducing the time between conceptual design and operational implementation while increasing the likelihood that innovative materials will meet real-world performance requirements.

Ultimately, NCOC exemplifies how a strategic approach to R&D—combining foresight, collaboration, and advanced computational tools—can transform scientific breakthroughs into technologies that provide tangible advantages on the battlefield, in aerospace applications, and across industrial sectors.

The Future is Clear and Tough

Nanocomposite Optical Ceramics (NCOC) represent a paradigm shift in materials science for infrared optics. By combining nanoscale engineering with innovative material composition, NCOC overcomes the long-standing trade-off between optical clarity and mechanical toughness. Its unique properties—high infrared transmission, exceptional fracture resistance, and thermal stability—position it as the “invisible shield” for next-generation defense technologies, enabling systems to operate reliably in the most extreme conditions.

As manufacturing processes continue to mature and scale, the potential applications of NCOC will expand beyond current defense programs. To fully realize this potential, sustained investment in research and development is essential, along with interdisciplinary collaboration and the integration of advanced modeling, AI, and machine learning. These tools accelerate the path from conceptual design to deployable technology, ensuring that innovations move efficiently from the laboratory to operational systems.

Ultimately, NCOC exemplifies how advanced materials can be more than scientific achievements—they are foundational enablers of capabilities that protect warfighters, enhance system performance, and secure the technological edge of the U.S. and its allies for years to come.