Introduction: War, Disruption, and the Race to Modernize Production

The last two years have seen major wars erupt in Europe and the Middle East, with violence spilling into wider regions and fueling unprecedented demand for defense hardware. From artillery shells to next-generation drones, militaries are racing to replenish stockpiles and equip forces for protracted conflicts.

Lee Timmins, Consulting Director at Project One, describes the current moment bluntly:

“Many of our defence customers are ramping up production to meet the needs of UK armed forces and our international partners… The increase in activity will be with us for some time.”

But scaling up manufacturing is easier said than done. Global inflation, disrupted supply chains, and a surge in raw material costs—exacerbated by conflicts in Ukraine and Gaza—have made expansion costly and complex. According to Timmins, “investment in additional capacity is not enough. Manufacturing must make a step change in overall effectiveness. Production losses must be driven down.”

The Rise of Industry 4.0 and Smart Manufacturing

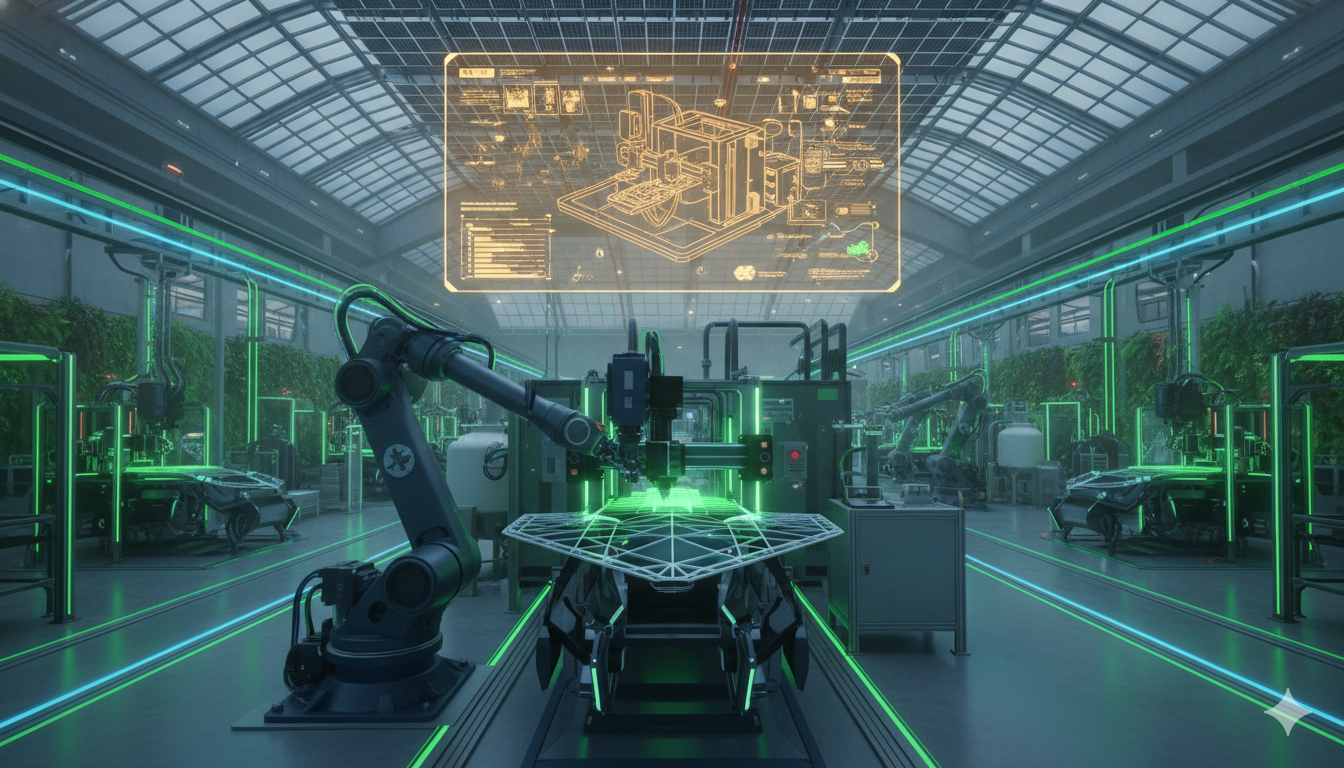

This is where Industry 4.0—the integration of cyber-physical systems, advanced automation, AI-driven analytics, and the Industrial Internet of Things (IIoT)—becomes more than a buzzword. It becomes a necessity.

Since its introduction in 2011, the concept of Industry 4.0 has moved from theory to transformative reality. Today’s manufacturing is defined by interconnected cyber-physical systems, AI-powered analytics, and the Industrial Internet of Things (IIoT), reshaping how goods are designed, produced, and maintained.

A smart factory is a cyber-physical production environment where machines, systems, and sensors are interconnected, enabling real-time data analysis, automated decision-making, and continuous process optimization. Businesses should adopt smart manufacturing to help streamline processes, increase productivity, stay competitive, and prepare for the future—including for unprecedented events, such as a pandemic.

This technological leap has reached far beyond the commercial sector, with defense and aerospace industries increasingly relying on smart, sustainable, and hybrid manufacturing to maintain operational superiority. For militaries, this shift is not merely about automation—it is about creating resilient, agile, and environmentally responsible production ecosystems that can respond rapidly to shifting geopolitical conditions. The need for adaptable manufacturing, capable of both high precision and rapid scalability, has never been greater, especially in light of global supply chain vulnerabilities and the accelerating pace of technological competition.

Key Technologies Powering the Smart Factory Revolution

Artificial intelligence is emerging as the strategic brain of modern manufacturing. By processing massive streams of sensor data, AI systems can predict equipment failures before they happen, optimize complex workflows, and minimize defects in mission-critical production. In military contexts, AI-driven generative design allows engineers to create lightweight, structurally optimized components that conserve material while maintaining battlefield durability. Computer vision tools, such as assembly-line monitoring platforms, are already improving worker training, safety, and process efficiency in defense factories.

Robotics and collaborative robots (cobots) have become indispensable in high-precision manufacturing environments. These systems work alongside human operators, combining machine accuracy with human adaptability. In defense production, autonomous robots equipped with advanced sensing and decision-making capabilities are increasingly used for hazardous, high-accuracy tasks such as explosive ordnance fabrication and aircraft component assembly.

Additive and hybrid manufacturing are redefining production speed and flexibility. 3D printing enables rapid prototyping and on-demand fabrication of complex parts, particularly valuable in remote or deployed military operations where traditional supply chains may be disrupted.

Additive manufacturing—better known as 3D printing—has transitioned from a prototyping tool to a full-fledged production method, capable of fabricating finished components and even small-scale infrastructure like bridges and modular buildings. The technology is now being combined with subtractive processes in hybrid manufacturing, which can produce complex parts more quickly while reducing material waste. Meanwhile, advanced computer numerical control (CNC) machines—powered by computer-aided manufacturing (CAM) designs—execute ultra-precise multi-axis milling, cutting, and drilling operations. Increasingly, these CNC machines are IoT-enabled, equipped with wireless sensors that feed data into analytics systems for predictive maintenance and process control.

The adoption of digital twins—virtual replicas of real-world systems—allows military engineers to simulate and stress-test components under battlefield conditions without wasting material. Paired with predictive modeling, these simulations streamline production cycles and improve reliability. Industrial IoT sensors further enhance this ecosystem by providing real-time health data on equipment, with edge computing enabling instantaneous, local decision-making—a vital capability for mission-critical manufacturing.

Sustainability Through the 6R Model

Defense manufacturing is under growing pressure to operate sustainably, moving beyond the traditional “reduce, reuse, recycle” framework to embrace the 6R approach: reduce, reuse, recycle, recover, redesign, and remanufacture. This expanded model prioritizes minimizing energy and raw material consumption, repurposing components after their service life, and restoring worn products to near-new condition.

The practical applications in military contexts are significant. Lightweight, fuel-efficient vehicles designed through generative AI reduce logistical fuel demands in combat zones. On-site 3D printing of spare parts cuts down on transport emissions and supply bottlenecks. Energy-efficient smart factories can lower operational costs while reducing the defense sector’s carbon footprint. These sustainability measures are no longer optional; they are central to military readiness in a climate-constrained world.

Global Case Studies: How Militaries Are Adopting Industry 4.0

India: From Self-Reliance to AI-Enabled Defense

India’s Make in India program has shifted into high gear. Hindustan Aeronautics Limited (HAL) is driving indigenous aerospace growth, supported by government-backed defense corridors. The Indian Army’s Rudrastra VTOL UAV—with its 170 km range and precision strike capabilities—demonstrates how AI, autonomous navigation, and modular production converge. Meanwhile, Grene Robotics’ Indrajaal autonomous counter-drone “battle dome” is redefining integrated air defense.

Europe: Additive Manufacturing at the Frontline

The European Defence Agency in 2025 commissioned an in-depth study on 3D printing’s role in reducing logistics burdens and enabling field repairs. Germany’s Rheinmetall Mobile Smart Factory—a containerized production unit—brings spare part manufacturing directly to deployment zones. Denmark’s Force Technology proved additive manufacturing could cut waste in F-35 components by over 95%.

Asia-Pacific: Australia’s Smart Supply Chains

Australia has embedded smart manufacturing into local defense supply chains. Hanwha’s expanded Avalon facility, backed by over USD 800,000 in government funding, is producing Huntsman howitzers and Redback vehicles with integrated IIoT systems for real-time quality control.

The U.S. Army’s Next-Gen Manufacturing Initiative

The U.S. Army Combat Capabilities Development Command (DEVCOM ARL) is spearheading a $50 million initiative to push the limits of defense manufacturing. This program focuses on developing engineered high-temperature materials for extreme environments, expanding advanced additive manufacturing capabilities for rapid deployment, and integrating novel processes supported by predictive modeling to boost product durability.

Performance assessment remains central to this strategy, ensuring that components not only meet design specifications but can endure the unpredictable realities of the battlefield. The initiative illustrates how the U.S. military is embedding smart, sustainable, and hybrid manufacturing into its long-term modernization plans, ensuring both strategic advantage and operational resilience.

Challenges and the Road Ahead

While Industry 4.0 offers transformative potential for the defense sector, its adoption is accompanied by formidable challenges. As defense manufacturing systems become increasingly interconnected—integrating IoT devices, cloud platforms, and AI-driven analytics—the attack surface for cyber threats expands significantly.

Cybersecurity threats loom large in connected manufacturing ecosystems, with over half of industrial leaders expressing concern about intellectual property theft and system sabotage. Advanced persistent threats (APTs) targeting supply chains, intellectual property, and mission-critical systems are already on the rise, making robust cybersecurity frameworks a strategic necessity. For smaller defense contractors, the high upfront capital expenditure for advanced robotics, additive manufacturing, and digital twins can be prohibitive, especially without government incentives or industry partnerships to offset costs.

Looking forward, AI-driven autonomous factories may become the norm in defense manufacturing, with circular economy principles embedded into supply chains to minimize waste and maximize reuse. Quantum computing could radically accelerate materials science breakthroughs, enabling the creation of ultra-strong, ultra-light components and revolutionizing logistics optimization for global military operations.

Conclusion: Manufacturing for Strategic Resilience

The fusion of smart, sustainable, and hybrid manufacturing is redefining both military and industrial production. By integrating AI, robotics, additive manufacturing, IIoT, and sustainable design principles, defense forces can achieve faster, more agile production with reduced environmental impact—ultimately enhancing operational readiness in an uncertain global landscape.

Whether it’s India’s AI-enabled UAVs, Europe’s deployable additive manufacturing hubs, or Australia’s smart defense supply chains, the trajectory is clear: the militaries that fuse technological innovation with agile production will lead the future of warfare and industrial resilience.

In the battlespace of the future, technological superiority will not rest solely on weapons systems, but on the manufacturing ecosystems that produce, maintain, and adapt them. Those who master smart manufacturing today will lead not just in industry, but in strategic capability tomorrow.