A ceramic is any of the various hard, brittle, heat-resistant and corrosion-resistant materials made by shaping and then firing a nonmetallic mineral, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

With such a large range of possible options for the composition/structure of a ceramic (nearly all of the elements, nearly all types of bonding, and all levels of crystallinity), the breadth of the subject is vast, and identifiable attributes ( hardness, toughness, electrical conductivity ) are difficult to specify for the group as a whole. General properties such as high melting temperature, high hardness, poor conductivity, high moduli of elasticity, chemical resistance and low ductility are the norm, with known exceptions to each of these rules ( piezoelectric ceramics, glass transition temperature, superconductive ceramics). Many composites, such as fiberglass and carbon fiber, while containing ceramic materials are not considered to be part of the ceramic family.

Ceramic material is an inorganic, non-metallic, often crystalline oxide, nitride, or carbide material. Some elements, such as carbon or silicon, maybe considered ceramics. Ceramic materials are brittle, hard, strong in compression, and weak in shearing and tension. They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments. Ceramics generally can withstand very high temperatures, ranging from 1,000 °C to 1,600 °C (1,800 °F to 3,000 °F). Glass is often not considered a ceramic because of its amorphous (noncrystalline) character. However, glassmaking involves several steps of the ceramic process, and its mechanical properties are similar to ceramic materials.

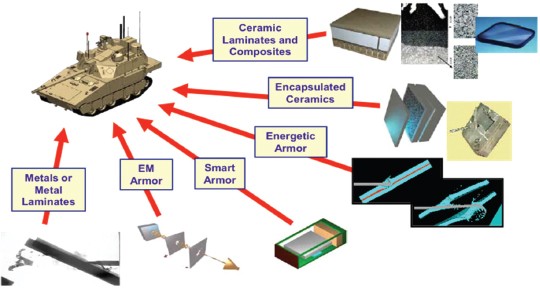

Ceramics for Military Body and Vehicle Armor

Current fighters today have been using high caliber guns which could inflict serious damage due to bullet’s high speed travel with enormous amount of kinetic energy. Thus armors both for individual personnel and vehicles have been developed and have been using specific materials to primarily counter and stop these types of weapons.

Kevlar which is made out of fibers was an early enhanced armor for soldiers designed to stop and catch bullets. It is an excellent antiballistic material as huge amount of energy should be exerted to damage this type of protective suite. However, Kevlar has also its limit. In order for Kevlar to be effective against small handgun bullets such as 9 mm bullet weighing 8.0 grams fired at 373 m/s, 16 layers of Kevlar is needed. Therefore, the thicker the layers of Kevlar the more effective it is against bullets. Thus thicker layers of Kevlar are necessary to protect soldiers in battlefield than protecting policemen.

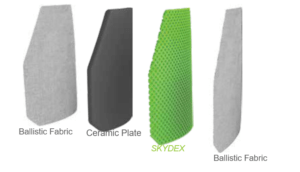

Ceramic plates are a different style of ballistic protection than kevlar or other fibers in that instead of “catching” a bullet, ceramics actually break the bullet. Ceramic ballistic plates have been used for decades because of their ability to break a projectile shot at it and reduce the impact caused by the projectile. In addition to their protective capability, ceramic plates are much lighter than their steel alternatives. Highly protective at a fraction of the weight means more agility and less fatigue for the user.

However, the downside of ceramic plates is that they can be easily broken or cracked if dropped or mishandled during everyday use. This fragility in rough environments reduce its operational effectiveness. SKYDEX has developed a range of easily integrated energy-absorbing materials that other drop protection for ceramic plates. Engineered from some of our thinnest geometries, SKYDEX offers multi-impact performance in a highly-resilient material to protect your ceramic plate.

When used as ballistic body armor, the numerous and versatile properties of ceramics allow for the speed of bullets to be reduced and ultimately transform the bullets into small fragments. Military personal protective equipment composed of technical ceramics has already been applied to special operations forces that require body, side and shoulder armor. Advanced protective equipment for other vulnerable areas of the body such as the hips, legs and arms are currently under development.

Technical ceramics exhibit a number of useful properties that make them the most common application for armor systems within the military and defense industry. These properties include: having a relatively low weight, high-performance during ballistic-scale impacts, an ability to withstand extremely high temperatures, low friction and resistance to wear, corrosion and hardness. Lightweight armors are advantageous for military soldiers to maximize their actions, to become more flexible and efficient inside the battlefield while carrying full battle load. Ceramic materials are appropriate for these protective armors due to its strong, durable and lightweight properties.

Ceramics are known to be one of the hardest materials. Unlike Kevlar which is primarily designed to catch bullets, ceramic armors break bullets. Unique properties and characteristics of high technology ceramics such as lightweight and hardness made ceramics the groundwork of modern military armor and the most important ceramic materials used for ballistic protection today are Aluminum Oxide or Alumina and Silicon Carbide.

Some of the ceramic materials that have been the most useful for military armor applications include Al2O3 (alumina), B4C (boron carbide) and SiC (silicon carbide), as well as a number of ceramic matrix composites (CMCs), such as Al2O3/ZrO2 systems. Of these materials, alumina is the most commonly utilized technical ceramic for body armor, as it exhibits hardness, refractoriness and modulus of elasticity at a much lower cost when compared to other commercially available technical ceramics.

For vehicle purposes, ceramic armors can be incorporated into the panels for military fighting vehicles and turrets, warships, helicopters and armored vehicles. Additionally, companies like Morgan Advanced Materials offer ceramics armor for high-security garages and warehouse doors, as well as for shields that are used to protect security cameras and other communication equipment. While one of the lightest yet the strongest ceramics material which is mainly used in tanks’ armor is known as Boron Carbide.

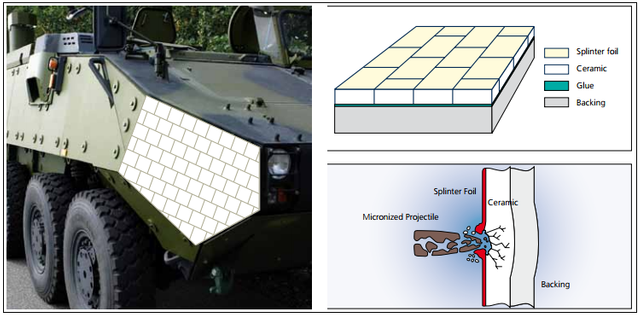

Ceramic armors such as trauma plates made out of boron carbides are designed to absorb and disrupt the kinetic energy of the bullet and reduced its impact. It is usually used as composite in ballistic vests and is durable enough to prevent bullet from penetrating the armor. Mainly, the structure of the lightweight composite armor is fundamentally based on four components; spall foil, ceramic, composite substrate and adhesive.

Owing to its excellent price-efficiency ratio, alumina is the preeminent ceramic armor material for vehicular applications. Only when an extremely low weight is required (e.g. for personal protection or for helicopters) silicon carbide materials may be used.

In a composite armor system, the ceramic is normally placed on the strike face, preferably perpendicular to the expected threat. Polymer fibers composed of polyaramide, polyethylene or polypropylene form the composite backing. The stiffening and structural enhancement of the individual polymer layers is achieved by impregnation and subsequent curing of the adhesive. Proper selection of adhesives, such as rubber, polyurethane or epoxies, results in the desired shore hardness, and thereby the required mechanical properties which can be tailored to the threat requirements.

Generally, the effectiveness of the entire composite system is centered primarily on the chemical bond of ceramic and composite substrate. Ceramic materials are known for its high compressive strength which then reduces the velocity of the bullet. The reduced speed of this bullet is completely absorbed by the elastic deformation in the composite substrate. For this purpose, spall protection is intentionally placed in front of the ceramic material.

The problem with this innovation is that ceramic material could not be able to sustain consecutive impacts and the material gradually loses its durability. But, engineers have somehow eliminated this problem by reducing the size of the ceramic tiles to its possible smallest structure; through this the impact will be distributed to every tile.

Russia Testing Ceramic Armor

Now the Russian military has announced that the Technodinamika Group—part of the state tech corporation Rostec —plans to complete the manufacturer’s trials of the unique ceramic armor for armored vehicles in 2021. “The manufacturer’s trials are currently underway,” said Technodinamika Group CEO Igor Nasenkov.

“Our product features such advantages as lightness and big resistance to various artillery and tank weapons,” explained Nasenkov. The corundum ceramic armor plates were developed by Ufa Aggregate Production Association. Corundum ceramics is a super-hard material produced on the basis of aluminum oxide. It typically contains traces of iron, titanium, vanadium and chromium. Because of its hardness, it can scratch almost every other mineral and its commonly used as an abrasive in sandpaper.

The corundum ceramic armor plates were developed by Ufa Aggregate Production Association. Corundum ceramics is a super-hard material produced on the basis of aluminum oxide. It typically contains traces of iron, titanium, vanadium and chromium. Because of its hardness, it can scratch almost every other mineral and its commonly used as an abrasive in sandpaper.

Tests will determine how corundum ceramics can be applied to tanks, but Rostec has already announced that it would begin serial production of the high-strength ceramic armor plate for use in personal body armor as well as for ground, air and naval equipment. When used in composite body armor it can act as a crushing layer where it can be more effective against armor-piercing bullets and shells than steel. When a bullet hits the ceramic armor, the core is deformed on the surface of the plate and is easily retained by the second layer of protection, which could include steel or polymer.

“The creation of ceramic armor is one of the most promising directions in the development of body armor,” Naskenko explained . “It is lighter and smaller in size, but at the same time more dense in structure than armor steel. Plates made of corundum ceramics are capable of protecting not only personnel, but also air, land and sea equipment from armor-piercing bullets and shells. Currently, work is underway to prepare for the serial production of products that will be supplied to manufacturers of personal body armor and combat equipment.”

During tests at the Russian Scientific Research Institute of Steel earlier this year, ceramic plates were fired at with a 7.62x54mmR SVD “Dragunov” rifle at a speed of 805-832 meters per second. The armor plates were able to absorb the rounds. While much heavier ballistic rounds would be fired at the Russian tanks, the corundum ceramic plates would also be far thicker as well.

Ceramics in Aircrafts

In addition to utilizing engineered technical ceramics for the outer protection of aircrafts in the form of panels, the resistance of these ceramics to high temperatures, vibration and other extreme mechanical conditions are useful for aerospace-grade electronic substrates, as well as lighting, antenna and sensor components.

Advanced ceramic materials are established in multiple, viable applications in aerospace design and manufacturing. Their value will continue to grow. Heat resistance, and more Beta alloys, cermet, composites. In fact, developers have obtained more than 8,000 patents related to aerospace-grade ceramics since the early 1980s. General Electric currently leads the pack with nearly 1,400 individual patents; its nearest competitors, including United Technologies, Safran, Siemens and Lanxide Technology, currently hold less than 800 patents each. Rolls Royce and Boeing hold approximately 200 patents each, while Northrup Grumman and Epistar hold even less than that.

Primary Uses. Ceramics are not simply a matter of future developments; they are vital to the current aerospace industry. While they can be used in a number of ways and to achieve several design and performance objectives, there are three primary applications for aerospace-grade ceramics today:

1. Heat Resistance. Ceramics are used to achieve heat resistance. The heat-insulating properties of ceramics have been known for centuries, and the materials are used for thermal control in everything from batteries, magnets, and semiconductors to insulating tiles within aircraft. Ceramics have been adopted for multiple applications the design of space vehicles, including thermal protection from the exterior exhaust and interior protection in the form of insulation.

2. Noncorrosive Qualities. Ceramics also are used for their noncorrosive qualities. Because both aerospace and aviation design and manufacturing involves numerous corrosive and potentially hazardous materials, including jet fuel, this type of protection is absolutely critical. Despite the effectiveness of current ceramic materials, metal corrosion is still a factor on modern aircraft.

3. Light Weight. Ceramics are used in aerospace and aviation design and production simply because they are a lighter alternative to metals. Smooth and typically free of any surface imperfections, this allows for greater payloads on aircraft, faster speeds for military-grade jets, and longer deadlines for space exploration.

Specifically, within the military aircraft sector, CMCs have shown to be a clear advantage over previously used metal components used in aircraft engines. CMCs are typically lighter than other metals by 30-50% and are capable of handling much higher operating temperatures, measuring above 1100 °C, which can improve fuel economy and efficiency in larger aircraft engines.

Ballistic Transparent Ceramics

For a material to be transparent, light must be able to transmit light through it without any significant absorption or loss in reflection occurring. As the continued research and development in the field of technical ceramics has allowed transparent ceramics to become commercially available in sizes of up to 900 cm2, military personnel are interested in the incorporation of this material into windows for laser-based communications. Defense laser systems that require protection from the field and high transmittance to ensure that light does not obstruct the transmitted image could especially benefit from transparent ceramics. The ballistic and high-performance mechanical properties of ceramics are also particularly useful for application in the windows and windshields of military vehicles.

Some other defense and commercial applications of transparent ceramics within the military sector include: Aircraft, Missle domes, Transparent armors, IR windows, Hyper-hemispherical domes, Laser windows, Military aircraft lenses, Semiconductor processing applications, and Scanner windows

However, the use of ceramics has actually paved the way for the use of more advanced materials. 3-D printing, still a relatively new technology, has the potential to introduce entirely new aerospace materials, products, and systems.

Ceramics types

The crystallinity of ceramic materials ranges from highly oriented to semi-crystalline, vitrified, and often completely amorphous (glasses). Most often, fired ceramics are either vitrified or semi-vitrified as is the case with earthenware, stoneware, and porcelain. Varying crystallinity and electron composition in the ionic and covalent bonds cause most ceramic materials to be good thermal and electrical insulators.

Crystalline ceramics

Crystalline ceramic materials are not amenable to a great range of processing. Methods for dealing with them tend to fall into one of two categories – either make the ceramic in the desired shape, by reaction in situ, or by “forming” powders into the desired shape, and then sintering to form a solid body. Ceramic forming techniques include shaping by hand (sometimes including a rotation process called “throwing”), slip casting, tape casting (used for making very thin ceramic capacitors), injection molding, dry pressing, and other variations.

Noncrystalline ceramics

Noncrystalline ceramics, being glass, tend to be formed from melts. The glass is shaped when either fully molten, by casting, or when in a state of toffee-like viscosity, by methods such as blowing into a mold. If later heat treatments cause this glass to become partly crystalline, the resulting material is known as a glass-ceramic, widely used as cook-tops, and also as a glass composite material for nuclear waste disposal.

Ceramics market

The electronics and electrical ceramics market is expected to grow by USD 2.94 billion, progressing at a CAGR of about 5% during the forecast period. Based on the application, the home appliances saw maximum growth in 2020. The market for home appliances is growing due to innovative offerings from home appliance manufacturers worldwide.

The increasing use of ceramics for energy storage is one of the major factors propelling the market growth. However, factors such as high production costs will hamper market growth.

By geography, APAC is going to have a lucrative growth during the forecast period. About 51% of the market’s overall growth is expected to originate from APAC. The rise in end-user applications such as electronics, automotive, medical, and military and defense will facilitate the electronics and electrical ceramics market growth in APAC over the forecast period. China and Japan are the key markets for electronics and electrical ceramics in APAC. Market growth in APAC will be faster than the growth of the market in other regions.

Some key Companies are 3M Co., CeramTec TopCo GmbH,CoorsTek Inc.,KYOCERA Corp.,Morgan Advanced Materials Plc,Murata Manufacturing Co. Ltd., Samsung Electronics Co. Ltd., SCHOTT AG, TAIYO YUDEN Mobile Technology Co. Ltd., TDK Corp.

References and Resources also include: