Introduction

Synthetic diamonds, often referred to as lab-created diamonds, are diamonds that are engineered in controlled laboratory environments to replicate the conditions under which natural diamonds are formed. Synthetic diamond, once regarded solely for its use in jewelry, has evolved into a game-changing material with a wide range of industrial, electronics, quantum, power, defense, and aerospace applications. Their chemical similarity to natural diamonds, consisting of pure carbon atoms, combined with properties mirroring those of their natural counterparts, has opened the doors to a multitude of industrial, electronics, quantum, power, defense, and aerospace applications. Its exceptional properties, including superior hardness, thermal conductivity, and electrical insulating capabilities, have positioned synthetic diamond as a revolutionary substance with the potential to reshape these sectors.

The Genesis of Synthetic Diamond

Synthetic diamonds, also known as lab-grown diamonds or cultured diamonds, are diamonds that are created in a laboratory environment. They are chemically and physically identical to natural diamonds, but they are typically much less expensive.

Unlike natural diamonds, which take millions of years to form deep within the Earth’s mantle, synthetic diamonds are grown in a controlled laboratory environment emulating the conditions in which natural diamonds are created. Synthetic diamond, man-made diamond that is usually produced by subjecting graphite to very high temperatures and pressures. These diamonds are chemically identical to natural diamonds (carbon) consisting of actual carbon atoms making them diamonds and also possess characteristics similar to natural diamonds, making them an ideal candidate for various high-tech applications.

Synthetic diamonds have been around for many years, but they have only recently become popular in the jewelry industry. This is due in part to the fact that the cost of producing synthetic diamonds has decreased significantly in recent years. Synthetic diamonds are also more ethical than natural diamonds. Natural diamonds are often mined in dangerous and inhumane conditions. Synthetic diamonds, on the other hand, are produced in a controlled environment.

Synthetic Diamonds Applications

Naturally-formed diamonds and synthetic diamonds have astonishing properties that lead to their wide applications. Its molecular structure, with strong covalent bonds, results in greater hardness than all other materials, ideal for cutters used in oil and gas drilling, where it enables longer tool lifetime by minimizing wear, reduces downtime and drives down operating costs and carbon footprints.

Cutting and Drilling Tools: Synthetic diamonds are celebrated for their exceptional hardness and wear resistance, making them the perfect material for cutting and drilling tools in industries such as mining, construction, and machining. Their extended lifespan and enhanced performance have significantly reduced downtime and operating costs.

Heat Dissipation: In the electronics sector, synthetic diamonds with outstanding thermal conductivity are employed as heat sinks. These diamonds are essential for high-power electronic devices, including computers and laser diodes, ensuring optimal performance and durability by efficiently dissipating heat.

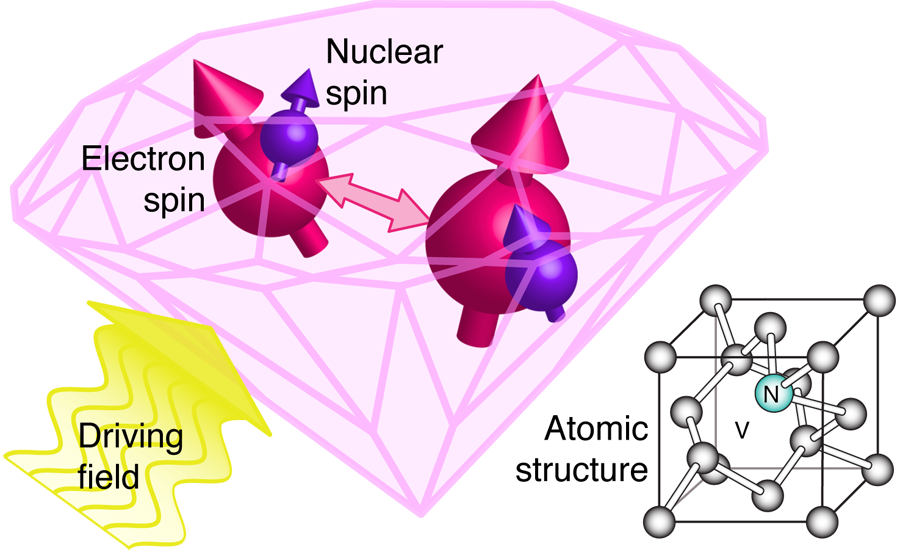

Quantum Sensing and Computing: Synthetic diamonds have unlocked new frontiers in quantum sensing and computing. Diamond has garnered attention as a distinctive material for quantum information processing, notably due to the Nitrogen-Vacancy (NV) centers within it that demonstrate quantum behavior even at room temperature. Diamond possesses a range of properties that effectively insulate the qubit from its external environment, encompassing its robust structure, exceptional heat conductivity, and a lack of electrical conductivity, making it an intriguing candidate for advancing quantum technologies. Nitrogen-Vacancy (NV) centers in diamonds enable the development of highly sensitive sensors for applications like magnetic resonance imaging (MRI), geological exploration, and quantum computers, thanks to their ability to exhibit quantum behavior at room temperature.

Power Generation and Energy

In the quest for more efficient and sustainable energy solutions, synthetic diamond plays a crucial role:

Nuclear Power: Synthetic diamond-coated sensors are used in nuclear power plants to monitor radiation levels accurately. Their exceptional resilience allows for long-term, reliable operation in extreme environments.

High-Power Electronics: It offers superior carrier mobility, breakdown electric field, and thermal conductivity, making it ideal for power electronic devices and grid management. In the emerging field of high-power electronics, synthetic diamond substrates provide excellent electrical insulation, reducing the risk of electrical breakdown and enhancing the efficiency and reliability of power electronic devices. These attributes are of paramount importance in the realm of electronic power distribution.

High-voltage power devices, including insulated-gate bipolar transistors (IGBTs), offer the advantage of improved efficiency and higher switching frequencies but are plagued by significant heat generation, necessitating advanced thermal management solutions. Synthetic diamond, renowned for possessing the highest thermal conductivity among all materials, with room-temperature thermal conductivity of up to 2000 W/mK—five times that of copper and ten times that of aluminum nitride—emerges as an ideal heat spreader. Its exceptional heat-conducting capabilities in all three dimensions make it the perfect material for thermal management applications, significantly enhancing the reliability of densely packed analog integrated circuits (ICs) featuring power elements such as MOSFETs and IGBTs.

High-voltage IGBT applications encompass power conversion for electric vehicles, train systems, aerospace power generators, and alternative energy distribution. In a notable test case using a 1200-V IGBT, replacing a ceramic substrate with a metalized diamond heat spreader more than halved the junction-to-case thermal resistance, consequently more than doubling the IGBT’s power rating. This supermaterial holds immense value across various electronic and electrical applications, including telecommunications and microelectronics, where heat accumulation can jeopardize circuitry integrity and performance. Notably, approximately 50% of electronic failures result from heat-related issues.

One prominent application of such diamond-based devices is in the power grid, where they can efficiently manage current and voltage surges, safeguarding equipment from damage. Unlike bulky silicon switches, these diamond-based counterparts can accomplish the same tasks in compact, finger-sized devices, promising significant advancements in power management technology.

Synthetic diamond possesses a compelling array of electrical properties, including a low dielectric constant, minimal loss, high electrical carrier mobility, and a broad electronic band gap. This unique combination enables the development of a myriad of electronic applications, ranging from high-power switches in power stations to high-frequency field-effect transistors and light-emitting diodes.

The Sparkling Revolution: A Journey into Synthetic Diamonds

Synthetic Diamonds in the Semiconductor Industry

Diamond’s exceptional properties, including ultra-high thermal conductivity, electric charge carrier mobility, high breakdown strength, and ultra-wide bandgap, make it a promising material for electronic and photonic applications. Overcoming the challenge of modifying diamond’s electronic properties through doping, researchers have turned to strain engineering, capitalizing on the surprising discovery that nanoscale diamonds can be elastically bent, resulting in significant local strain changes. The ability to modify diamond’s band structure through elastic strain engineering opens doors to various applications, from micro/nanoelectromechanical systems to optoelectronic and quantum technologies. This groundbreaking research signals a promising future for diamond-based technologies.

Diamond as the Next Semiconductor: With silicon approaching its physical limits in the semiconductor industry, synthetic diamond is emerging as the next-generation ultra-wide bandgap semiconductor.

Diamond is often hailed as the ultimate semiconductor due to its inherent superior physical properties compared to conventional semiconductors. Notably, diamond possesses a band gap five times wider than silicon (Si), resulting in a 30-fold higher breakdown field. This characteristic allows for the application of higher output bias voltage ratios, consequently increasing available power. Moreover, diamond exhibits an electron mobility three times greater than Si, resulting in reduced on-site resistance and power consumption during operation. Its exceptional thermal conductivity, ranking highest among all known materials, ensures efficient heat dissipation during high-power operation, leading to minimal temperature rise for a given power consumption. Diamond’s drift velocity, akin to that of gallium arsenide (GaAs), positions diamond transistors to excel in delivering high radio-frequency (RF) power capability, akin to GaAs transistors. In summary, diamond semiconductor technology holds the promise of revolutionizing high-frequency, high-power electronic devices, aligning with both energy efficiency and environmental sustainability imperatives.

Notably, diamond boasts the highest thermal conductivity among all known materials, ensuring efficient heat dissipation during high-power operation and minimal temperature rise for a given power consumption. In a semiconductor context, this becomes crucial as silicon nears its limitations due to thermal issues.

Diamond’s drift velocity is comparable to that of gallium arsenide (GaAs), enabling diamond transistors to deliver high radio-frequency (RF) power capability akin to GaAs transistors. Diamond semiconductors hold the potential to revolutionize high-frequency, high-power electronic devices while aligning with energy efficiency and environmental sustainability goals.

What sets diamond apart is its unrivaled thermal conductivity, outperforming all other materials. The electronic industry’s growing demand for synthetic diamonds stems from their critical role as a heat-enabling technology, preventing overheating in silicon and other semiconductor materials. Synthetic diamond’s capacity to act as an efficient heat sink has made it indispensable in ensuring the longevity and performance of electronic devices, paving the way for a potential revolution in diamond-based technologies.

The data transfer rate in communications is increasing very rapidly. Therefore, electronic devices that operate at higher frequencies and generate higher output power are urgently needed for the present and future communications systems. On the other hand, from the environmental and energy-saving viewpoints, higher power efficiency from semiconductor devices is required at the same time. Diamond semiconductor will satisfy all of these requirements.

While diamonds have proven highly effective, their production costs have remained a significant hurdle. Moreover, the adoption of diamond gained momentum with the refinement of the Chemical Vapor Deposition (CVD) process, enabling the growth of high-quality single crystal diamonds. This breakthrough has opened doors to a future where diamond-based semiconductors may revolutionize the electronics landscape.

Optical Windows: Synthetic diamond’s wide spectral band, spanning from ultraviolet to far-infrared and the millimeter-wave microwave range, coupled with its mechanical and thermal properties, makes it the material of choice for optical windows in high-power lasers, solid-state lasers, and gyrotrons, ensuring stable and enduring high optical quality. Single crystal synthetic diamond and polycrystalline CVD diamond have established themselves as solutions in various molecular spectroscopy applications, including synthetic diamond ATR prisms in FTIR spectroscopy.

High-Temperature Semiconductor Devices: The high thermal conductivity of synthetic diamond positions it as a critical material for high-temperature semiconductor devices, catering to industries such as industrial, oil drilling, and aviation. Its ability to operate reliably at high temperatures enhances device efficiency and lifespan.

The increasing demand for high-temperature semiconductor devices, powered by industries such as industrial, oil drilling, and aviation seeking robust solutions for extreme operating conditions, has catalyzed the development of a comprehensive portfolio of such devices, including synthetic diamond-based solutions. These devices are essential as semiconductor characteristics degrade with rising temperatures, necessitating stringent quality assurance through characterization and qualification processes. The market for high-temperature semiconductor devices, including innovative applications of synthetic diamond, is experiencing rapid growth, thanks to benefits like cost reduction and improved efficiency. It finds traction across diverse industries, including electronics, defense, aerospace, automotive, and optoelectronics, all requiring reliable high-temperature semiconductor solutions for harsh environments.

Flexible Wearables: Synthetic diamonds, with their superior heat-dissipation properties, have paved the way for flexible and transparent wearable technology. These diamonds prevent devices from overheating, ensuring more powerful and durable wearable devices with a longer lifespan.

Nuclear Batteries: Researchers have developed nuclear-powered batteries using synthetic diamonds. By encapsulating radioactive materials within diamonds, these batteries generate electricity without moving parts, emissions, or maintenance. They hold promise for applications in remote and long-lasting power sources. Potential applications for these batteries include scenarios where charging or replacing traditional batteries is impractical, such as in pacemakers, satellites, high-altitude drones, or spacecraft.

Despite their relatively low power output compared to current battery technologies, these diamond batteries boast an exceptional lifespan that could revolutionize long-term power solutions for various devices. When utilizing carbon-14, it would take approximately 5,730 years for the battery to reach 50 percent power, a timeframe nearly as old as human civilization itself.

Unlike conventional batteries, this innovation has no moving parts, produces zero emissions, and requires no maintenance. By encapsulating radioactive material within diamonds, a solution is created for long-term nuclear waste management while simultaneously providing a continuous source of clean energy.

The prototype ‘diamond battery’ introduced by the researchers of University of Bristol, currently employs Nickel-63 as the radiation source. However, their ongoing efforts aim to significantly enhance efficiency by incorporating carbon-14, a radioactive variant of carbon found in graphite blocks used for moderating reactions in nuclear power plants.

This innovation also addresses the challenge of safely storing the substantial quantity of graphite blocks in the UK, which amounts to nearly 95,000 tonnes. By extracting carbon-14 from these blocks, their radioactivity diminishes, reducing the cost and complexity associated with nuclear waste storage.

Synthetic Diamonds in Defense and Aerospace

Advanced Defense Applications: Synthetic diamonds have emerged as a versatile super material for defense applications. Applications such as broadcasting stations, communications satellites, and radars require higher output powers and frequencies, for example, 120 W and 10 GHz, respectively, for communications satellites. Such performance is beyond the ability of conventional semiconductor devices, so these applications still rely on traveling-wave tubes, which are vacuum tubes. However, the power efficiency of vacuum tubes is low because a large proportion of their input power is consumed as heat. Therefore, from the environmental and energy-saving viewpoints, vacuum tubes should be replaced by semiconductor devices.

They are employed in high-power radars, communications and electronic warfare systems, Directed Energy Weapons (DEWs), MEMS applications, and aerospace applications. Their radiation resistance, mechanical strength, and thermal conductivity make them invaluable in harsh environments.

Diamond Lasers: Researchers have developed diamond lasers with extraordinary power ranges. Their high-energy beams enable more precise and efficient targeting, with applications in defense, remote sensing, bio-imaging, medicine, and quantum science.

In the Laser & Optics industry, Associate Professor Rich Mildren and his team have made significant strides in diamond laser technology, achieving a remarkable 400 watts of power output, a substantial advancement from just a few watts five years ago. This achievement pushes the boundaries of conventional lasers, mainly attributed to diamond’s exceptional thermal conductivity and heat dissipation capabilities. This high-energy laser beam not only enhances precision by enabling tighter focusing on targets but also extends its range, making it valuable in applications such as defense against missile threats, remote sensing, bioimaging, medicine, quantum science, and space debris management. Researchers at MQ Photonics Research Centre harnessed Element Six’s low-absorption single-crystal CVD diamond to create a diamond laser with 20 times more power than previous systems, boasting an impressive 380 watts of output power, capable of cutting through steel. Synthetic diamonds are also pivotal in Raman lasers, offering a power scaling improvement of over two orders of magnitude

At the 2019 China International Jewellery Fair, a subsidiary of the China North Industries Group Corporation (Norinco), a major Chinese arms manufacturer, presented synthetic diamonds that have sparked interest due to their potential dual purpose. A report in the Global Times suggested that these diamonds might be intended for use in laser-based weaponry, citing insights from Chinese military analysts. This suggests that these synthetic diamonds hold strategic significance, bridging the worlds of advanced materials science and defense technology.

Laser Diode Arrays: Laser Diode Arrays, known for their high-power capabilities, find applications in a wide range of fields, from industrial material processing like welding and surface treatments to medical procedures such as tattoo removal and laser surgery. These arrays, often generating hundreds of watts, consist of multiple closely spaced emitters on a single chip, necessitating efficient thermal management for optimal performance.

Integrating a diamond heat spreader between the diode array and the submount serves as a game-changer, effectively dissipating heat away from localized emitter hotspots. This innovation not only significantly boosts beam intensity and quality by allowing for tighter emitter spacing within the arrays but also extends the lifespan of the diode arrays. The introduction of diamond heat spreaders marks a noteworthy advancement in enhancing the efficiency and longevity of high-power laser-diode arrays, revolutionizing their potential across various applications.

Space Exploration: In space missions, synthetic diamond’s radiation resistance, chemically and biologically inert properties, mechanical strength, and thermal conductivity have proven invaluable for components subjected to the harsh conditions of outer space. They are used in instruments aboard spacecraft, enhancing overall safety and performance.

Its resilience makes it an ideal choice for space missions, enduring the relentless radiation of the extraterrestrial environment over extended periods. Notably, Raytheon has incorporated synthetic diamond into various electronic components, even finding its application in instruments aboard the Mars rovers Spirit and Opportunity. This demonstrates the versatility and reliability of synthetic diamond in space technology, further solidifying its role as a space-age material of choice.

Radar and Communication Systems: Synthetic diamond-based components are used in radar and communication systems due to their exceptional electrical insulating properties, ensuring interference-free signal transmission and reception.

As the demand for higher data transfer rates in communication systems continues to surge, there is an urgent need for electronic devices that can operate at elevated frequencies while delivering increased output power. Simultaneously, there is a growing emphasis on environmental sustainability and energy efficiency in semiconductor devices. Diamond semiconductors have emerged as a solution that can address these multifaceted requirements.

Critical applications such as broadcasting stations, communications satellites, and radar systems demand higher output powers and frequencies, exemplified by requirements of 120 W and 10 GHz for communications satellites. These performance benchmarks exceed the capabilities of conventional semiconductor devices, leading to a continued reliance on vacuum tubes, known as traveling-wave tubes. However, vacuum tubes exhibit low power efficiency, with a significant portion of input power dissipating as heat. From environmental and energy-saving perspectives, there is a compelling case for replacing vacuum tubes with semiconductor devices.

Armor and Protective Coatings: The incredible hardness and durability of synthetic diamond make it an ideal material for armor and protective coatings on military vehicles, aircraft, and even personal gear, enhancing overall safety and protection.

Conclusion

Synthetic diamonds have transcended their origins in the jewelry industry to become indispensable materials in advanced sectors ranging from defense and aerospace to electronics and quantum computing. Their exceptional properties, including hardness, thermal conductivity, and electrical insulating capabilities, have positioned synthetic diamonds as a revolutionary substance. As technology continues to advance, the potential applications of synthetic diamonds are boundless, ensuring that their impact on various industries will only grow in significance. The synthetic diamond revolution has truly begun, heralding a new era of innovation and progress across the industrial landscape.

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis