Operation of Armed Forces personnel in harsh military terrains for extended tenure period necessitates protection from elements and battle hazards. Harsh military terrains exert profound effects on the physical and physiological performance of the soldiers and can impart serious health hazards on inadequately protected soldiers resulting in mission failure and avoidable loss of lives. Harsh military terrains can be Mountain environment characterized by treacherous terrains with extreme cold and hypoxia, Deserts characterized by extreme heat stress, Depths of underwater that can pose life threatening situation in case of a distressed submarine, Aviation hazards (such as deadly G-forces faced by fighter pilots during G-manoeuvres and fire hazards that may result from crash) etc. Clothing being the first layer of protection for the wearer, forms an important protective measure in military operation against combat and environmental hazards.

Military fabric is not just about uniforms. It includes a wide variety of functions. Ponchos, Tents, Backpacks and Utility Belts, Personal Protective Equipment (PPE) Linings in Rockets, Cords, Ropes, and Cables, Straps and Sheaths for Carrying Weapons, Helmet Coverings , Flags, Bedsheets & Mattress Fabrics, Hats, Gloves, and Belts.also constitute military fabric.

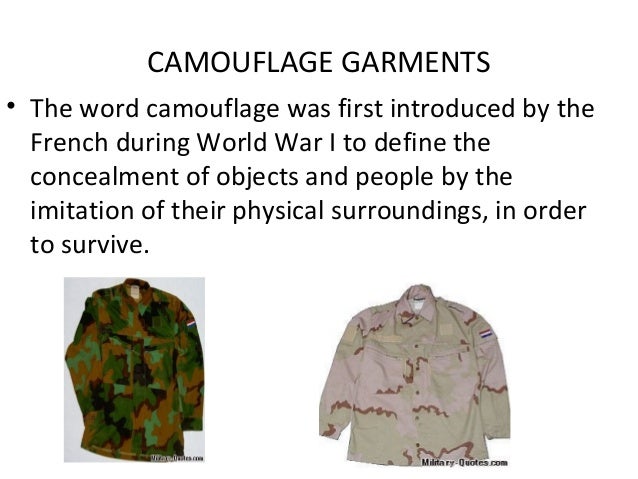

Demand for military fabric varies, depending on various factors including the level of protection required. Fabrics are customised to fight extreme weather conditions like heat, cold, wind or rain. Textiles need to offer protection against ballistic impact, nuclear, biological and chemical threats. The basic requirement of military fabric is to provide camouflage in the visible spectrum, as well as in ultra-violet and infra-red wavelengths.

Military fabrics are made from more than just your standard fabrics like cotton or canvas; they are also made from things like polyester, vinyl, polyester vinyl composites, and acrylics to name a few. Soldiers stationed around the world wear and use specialty military fabrics every day. From the uniforms to the helmets they wear, specialty fabrics make up an integral part of the tools they need to protect and serve their countries.

So, each nation has something different on their shopping list for military fabric. Following this, the textile industry offers customised clothing to the military according to specifications. Light weight, fire retardant uniforms with buoyant properties are in demand in the Canadian forces. New Zealand Navy needs hoods and hand gloves made of Kevlar fibre. National Aeronautic Space Authority (NASA) has prescribed clothing of special property to protect soldiers from the critical environment during warfare.

Russian military uniforms are among the finest contemporary designs with a perfect balance between conventional and contemporary. The modern Russian military uniform is made of a variety of materials with multiple layers. The United States is one of the most active nations in developing new safety measures for military uniforms is concerned. Most of the research and development pertaining to military fabric is also being carried out there. This explains the technically advanced military fabrics used by its defence forces. Apart from reliance on technically sound fabrics, the United States of America updates its camouflage patterns as well. Its new camouflage pattern uniforms were launched in the market on 1 July 2015.

India’s defence forces have adopted their own Disruptive Pattern Material for camouflage uniforms. Indian defence forces are one of the major users of protective textiles, but there is a huge gap between the military textiles of developed countries. According to a study conducted by FICCI, many materials currently in use for military purposes are outdated and need immediate upgrading. The domestic textile industry in India is seeking a share of the Rs 2,000 crore annual clothing requirements of more than 15 lakh defence and 12 lakh paramilitary personnel, as India’s textile sector has the capability to deliver world-class military gear.

Defence Research and Development Organisation (DRDO) is helping Indian textile industries produce yarns to end the reliance on imports of Chinese and other foreign clothing for making military uniforms. Director of Directorate of Industry Interface and Technology management (DIITM) at DRDO, Dr Mayank Dwivedi said that for Indian army’s summer uniform alone, the approximate requirement of the fabric is 55 lakh metres and if all the requirements of Navy, Air Force and Para Military forces are added then the requirement may go well beyond 1.5 crore metres per annum.

The DIITM Director further said that the scope of technical textiles such as glass fabric, carbon fabric, aramid fabric and advanced ceramic fabrics is enormous in defence application. Some industries in Ahmedabad and Surat are manufacturing advanced fabrics being used in defence applications. It was emphasised that the use of advanced textiles blends using yarns of polyester/ nylon 6,6 / cotton/polyurethane/rayon will enhance operational capabilities and comfort of Indian Armed Forces.

Military Requirments

The term “military grade” is a broad term that can be used in reference to the quality of a product or even the materials used to develop said product. A basic definition is “environmental worthiness and overall durability of material system design”, based on a set of tests established by the US Department of Defense that test military standards of durability and performance.

Textiles for military uniforms face a complex set of challenges. Military fabrics are made to withstand the rigors of military life. The surrounding environments such as desert, jungle or extremely cold areas as well as the nature of the situations involved pose a threat to the soldier’s safety. Therefore, the improvement and development of fibrous materials, textile structures and finishing processes can bring new perspectives for saving lives.

That means these fabrics can stand up to things like inclement weather, and they can repel the harmful ultraviolet rays of the sun, and most of all, these textiles are dependable. That means these fabrics allow soldiers to do their work without worrying. For example, it’s important that things like tents and other military fabric structures stay tight on the frame, won’t tear easily and are waterproof; that’s why performance fabrics/specialty fabrics are so important in the creation of military fabric products. If a soldier has to worry about his tent, his mind is not on the mission at hand.

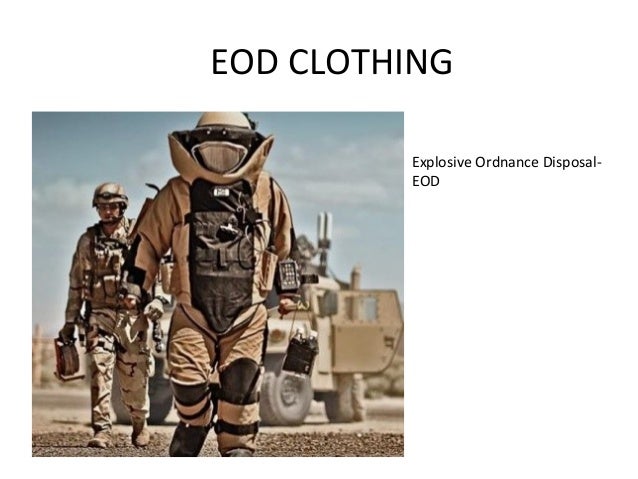

There must be a provision for durability, comfort and protection and also should withstand a wide range of hostile environments. A soldier’s mobility, survivability and stamina are closely linked with comfort and fit of their outfit. They must provide protection, durability and comfort in a wide range of hostile environments. The general requirements of military textiles, include damage resistance, comfort, sweat management, cold-weather conditions and the integration of high-tech materials into uniforms. The protective role of military textiles, cover such areas as high-performance ballistic fibres, textiles for chemical and biological protection, camouflage materials and military fabrics for flame protection.

Military grade textiles are, therefore, textiles that are modified and designed to be high-durability, tough, and steadfast, and can be applied to numerous military uses. Some examples of the durability features considered in the development and production of military grade fabrics include staying strong through “extreme weather conditions (heat, cold, wind, and rain), against ballistic impact, and against nuclear, biological and chemical threats”, among other common threats to the fabric and wearer in the military field (Source). Another feature that has to be considered in the development of military grade fabrics is functionality. While durability is an important feature, the fabric should be lightweight, comfortable, and maybe even have moisture wicking or temperature controlling capabilities depending on fabric application.

Military grade textiles can be applied beyond military uniforms; these textiles can be used from anything from carrying cases for tools and electronics, to wearable vests to carry technology or weaponry, or even to holsters to carry both medical and military supplies, and so much more. The military grade textile is constantly progressing, and the most recent developments concern the integration of nanotechnology into these textiles, making them not only high function, but also intelligent textiles that can aid in anything from camouflage to specified muscle stimulation to enhance wearers strength. In the future, military grade textiles and smart textiles could very well be synonymous, including self-healing fabric technology, graphene applications, and more. Military grade fabrics are, in a way, the ultimate performance textile in terms of protection, intelligence, and function.

Technology trends

A great deal of research is being carried out by military/defence research laboratories worldwide in collaboration with industries to develop technical textiles incorporating suitable smart material finishes for the alleviation of the dangers associated in the combat terrain. Extended Cold weather clothing ensemble, High Altitude Pulmonary Oedema chambers, Anti-G suits, Flame retardant overalls, Submarine Escape Sets, Chemical warfare protection ensemble, liquid cooled garment for protection against hyperthermia etc., are fabricated from variety of technical textiles having special material properties.

Fabric used for military purposes have to undergo regular modifications to meet challenges posed by modern warfare techniques. Nanotechnology is one of the deciders that influences military textile. With nanotechnology, it is possible to enhance functionality of military fabric. According to TechNavio’s analysts, the smart textile market for military will grow globally at a compound annual growth rate of 10.35 per cent between 2014 and 2019. This figure indicates that military fabric has gone on to become one of the top priorities.

Nanotechnology has made military textile light-weight, an important pre-requisite for the wearer who often carries heavy equipment. Nanotechnology helps fabric change colour and pattern according to the environment, offering better camouflage. Some other popular military textiles in demand include fabrics with fibres to invigorate muscles to make physical activity like jumping, running and lifting easier to perform. Fire retardant textiles, water proof fabrics and anti-stain fabrics are some of the general requirements for military textile for which polyester, cotton, high tenacity polyester, para-aramid synthetic fibres, moisture wicking fabrics etc are used.

With rise in risks during military operations, wearable technology has become even more significant. Electronic textiles are capable of converting sunlight or artificial light into direct current electrical power. Smart textiles will ensure soldiers wear next-to-skin garments that keep a check on physical fitness status like heartbeat, blood pressure, respiration and body temperature.

However multifunctional the fabric is, the main concern remains its weight. “Lightweight, wearable power is very desirable since it will replace some batteries, which add weight to the soldier’s load. The key to future advancements is the development of electronic circuits that are entirely made of fabric,” said senior officer Dr Eugene Wilusz of United States Army Natick Soldier Research, Development and Engineering Centre (NSRDEC).

The United States Naval Research Laboratory has come up with solar array blankets that offer high power output along with being light weight and flexible. Most of the current e-textiles available for the military is bulky, lacks durability and restricts movement. So, researchers are concentrating on incorporating flexible antennas, power networks, sensors etc into the clothing. Among the new approaches, military textile harvesting kinetic energy and photovoltaic’s are popular. “We’ve always looked at the uniform as a potential data and power bus. It could transport data and power throughout the soldier system,” pointed out textile technologist at the NSRDEC, Carole Winterhalter.

Military standards and Testing

A military grade product will be made from top-quality and high durability parts that will maintain their forms during high environmental stress situations. “Mil-spec” is a term that refers to a set of military specifications that are followed by manufacturers to produce military grade goods. These standards are defined in MIL-SPECs, which outline defense specifications and standards established by the Department of Defense (there are currently around 25,000-30,000 active specifications today for anything the military currently utilizes – from textiles, to tires, to hoses, to footwear, etc.). These specifications may ensure the safety of our military personnel, but how are the subjects put to the test before they make it into the field?

*Products that have been developed for the US military all must share one feature: the product must be Berry Compliant. Berry compliance means that all materials – raw and produced – must be made or grown in the US. This limits where the material can be sourced from and where products can be made during the manufacturing of military grade goods.

There are many features that need to be tested for in order to make sure that the textile will uphold maximum protection. These include (but are not limited to):

Heat and Flame Resistance/Retardancy and Extreme Freezing Temperatures: This is to make sure that the textile will not burn when exposed to extreme temperatures or an open flame, and will not freeze when in extremely cold temperatures. The ability for the fabric to protect whatever it is covering (be it a human in the case of a uniform or specialized equipment in the case of a carrying case) is crucial to it’s performance.

Air Permeability: This is the breathability of the fabric and ease with which air passes through it.

Physical Testing (Tensile Strength, Abrasion Resistance, Strength, Denier Thickness): This is one of the most important features; the ability for the textile to hold up to weathering, abrasion, and tears. The military requires only the most durable textiles, and by testing the durability beforehand it prevents any unexpected material failures in the field. While testing for fabric durability, it is also important to test for durability of the final product.

Antibacterial Properties: In most cases, military fabrics will have coatings that prevent bacteria from growing and spreading. This is an ideal feature to have not only in uniforms, but also in rucksacks and backpacks, as it protects what is inside.

Antifungal Properties: Similarly, fungus can grow in wet and dark areas, such as inside of a closed rucksack that had dampness trapped inside. A textile coating can also prevent this.

This list of features just scratches the surface of what military textiles are tested for. Other features include water resistance, moisture wicking, drying time, and more specific needs.

Military Textile Materials Testing Market

Global Military Textile Materials Testing market is segmented into: Combat Uniforms, Sleeping Bags, Cold Protective Clothing, Immersion Suits and Other. Military textile materials testing is the technique offered in checking and confirming the quality of military textiles, which adds invaluable benefits to the military sector. The military textile materials have various properties, which are achieved by various processes in chemical finishing, i.e. certain substances are applied to the surface of the textile fabric where they are retained, not penetrating into the yarn.

The military textile materials testing market include various tests for thermal insulation, wear comfort and skin sensorial comfort. One of the most prominent features of comfort for military textile materials is the property of thermal comfort, i.e. comfort or discomfort associated with how hot or cold one feels. In the wear comfort test of textiles, there is a difference between thermo-physiological aspects of the material i.e. maintaining the moisture and warmth, and the way textile looks on skin. The thermal insulation test for combat uniforms, sleeping bags and cold protective clothing and immersion suits can be measured by using the thermal manikins. Skin sensorial comfort test is done for the sensitivity of skin, which is a significant aspect that influences wear comfort.

The necessity of perfect comfort and protection of the military personnel in extreme environments along with the various thermo-physiological properties of textile materials boosts the demand of military textile materials testing and thus in turn fuelling the growth of global military textile materials testing market. The main aim of military textile material testing is to meet industry and regulatory standards and to determine that textile products and their components must meet the required specifications for intended use and expected life cycle.

High cost of testing and unavailability of skilled labours to perform the critical tests are the major challenges for the military textile material testing and thus hampering the growth of global military textile materials testing market. Top Leading Companies of Global Military Textile Materials Testing Market are Hohenstein Institute, Element Materials Technology, Precision Testing Laboratories, UL LLC, VARTEST LABORATORIES and SGS SA.

Regional segments

With increased awareness among developing nations about the safety of defence personnel, the market for military fabric is expanding fast. In the past few decades, the textile material technology has been upgraded regularly. This has resulted in increased usage of technical and smart textiles for the defence services.

Considering regions, Europe accounts for major share in the sales of military textile materials testing, however the growth rate is expected to decline over the forecast period due to substantial reduction in the demand of military textiles. The demand for military textile materials testing is expected to increase in the Asia Pacific and MEA region. Currently, demand for military textile materials testing in developed regions such as North America and Europe is a result of the establishment of national defence force to fight the rising waves of terrorism. The replacement of old fashioned military textile materials testing create an adequate demand for latest military textile materials testing and thus in turn propelling the growth of global military textile materials testing market.

Current military textile specifications in India do not lay emphasis on comfort and safety depending on changing battle field conditions. High mobility and smart looks, which are essential requirements in the US, are often given low priority in India. The main reason for this is lack of availability of upgraded fabrics in developing nations like India and Pakistan.

Nevertheless, India’s technical textile sector is expected to grow at 20 per cent per annum between 2015 and 2016. According to a PHD Chamber of Commerce study, India’s technical textiles market is likely to reach US$ 32 billion by 2023. This can give a boost to protective clothing required by the armed forces as well.

References and resources also include:

http://blog.fieldtexcases.com/mil-spec-textile-testing/

https://www.fibre2fashion.com/industry-article/7597/global-perspective-on-military-

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis