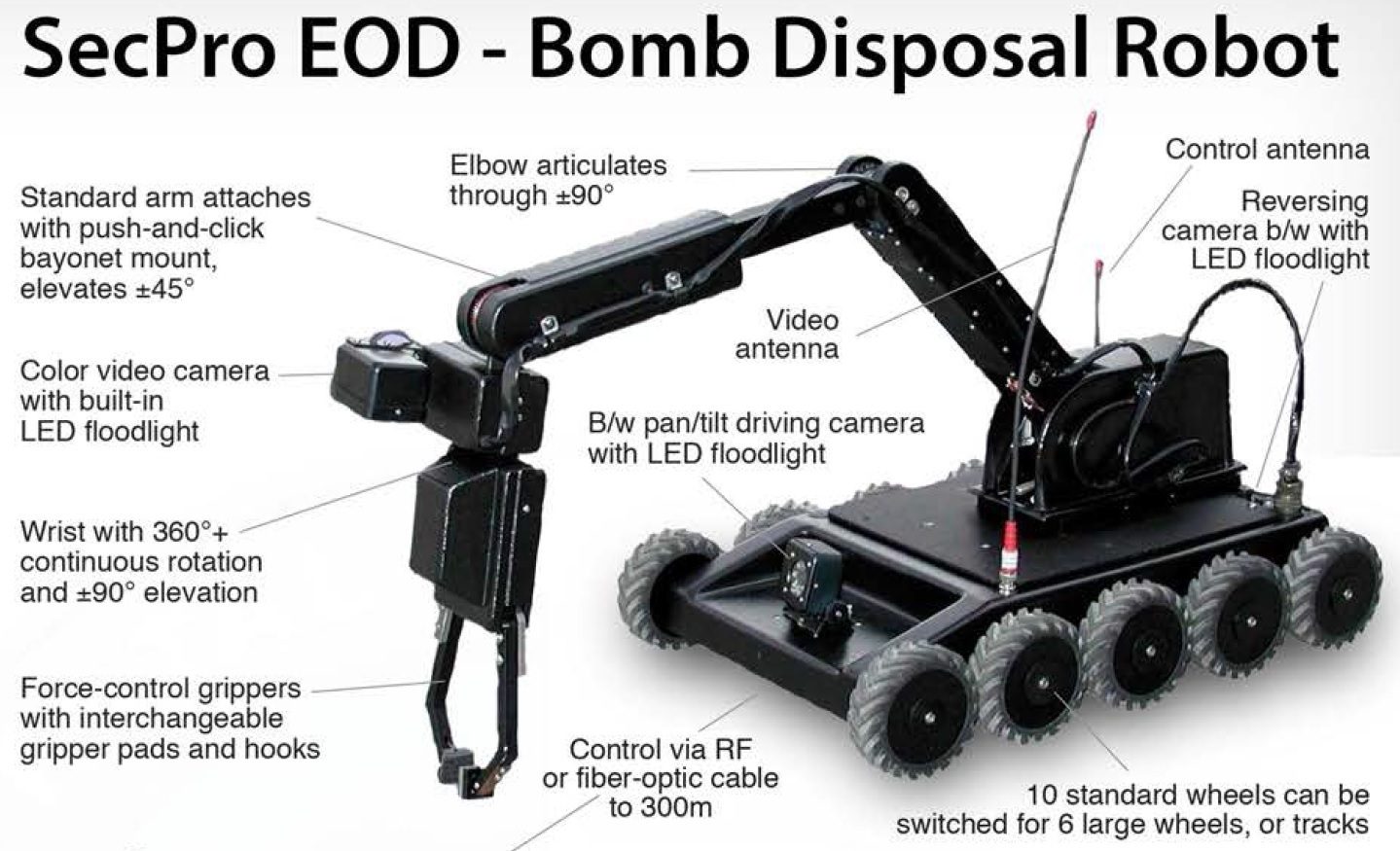

EOD operators or ammunition technical officers conduct some of the military’s most dangerous jobs, who has the daunting task of dismantling, defusing and disposing bombs and other explosive ordnance, often in the most hostile and challenging of environments. Making this job safer are bomb disposal robots, unmanned vehicles capable of disabling explosive devices without endangering human lives.

IDST Pro Access Required

This analysis is part of IDST premium intelligence.

Subscribe to Continue ReadingAlready a member? Log in