In 2009, the U.S. Navy began construction of the first new type of aircraft carrier in nearly thirty-five years. The Navy refers to its newest aircraft carrier, the USS Gerald R. Ford, as “4.5 acres of sovereign U.S. territory. Gerald R. Ford is a class of supercarriers being built to replace some of the United States Navy’s existing Nimitz-class carriers.

In recent years, a number of countries, China, Russia, and Iran, have accelerated investments in anti-access/area denial (A2/AD) capabilities such as advanced air defense systems, anti-ship cruise and ballistic missiles, submarines, and aircraft carriers. Long-range precision guided anti-ship missiles are increasingly able to target and destroy aircraft carriers at distances as far as 1,000-miles off shore. Chinese-built DF-21D missile is referred to as a “carrier-killer” is able to destroy targets more than 900 miles off shore. These technologies and weapons systems allow enemies to attack carriers at increasingly longer distances make the platforms more vulnerable and degraded power projection dominance in a potential future combat environment.

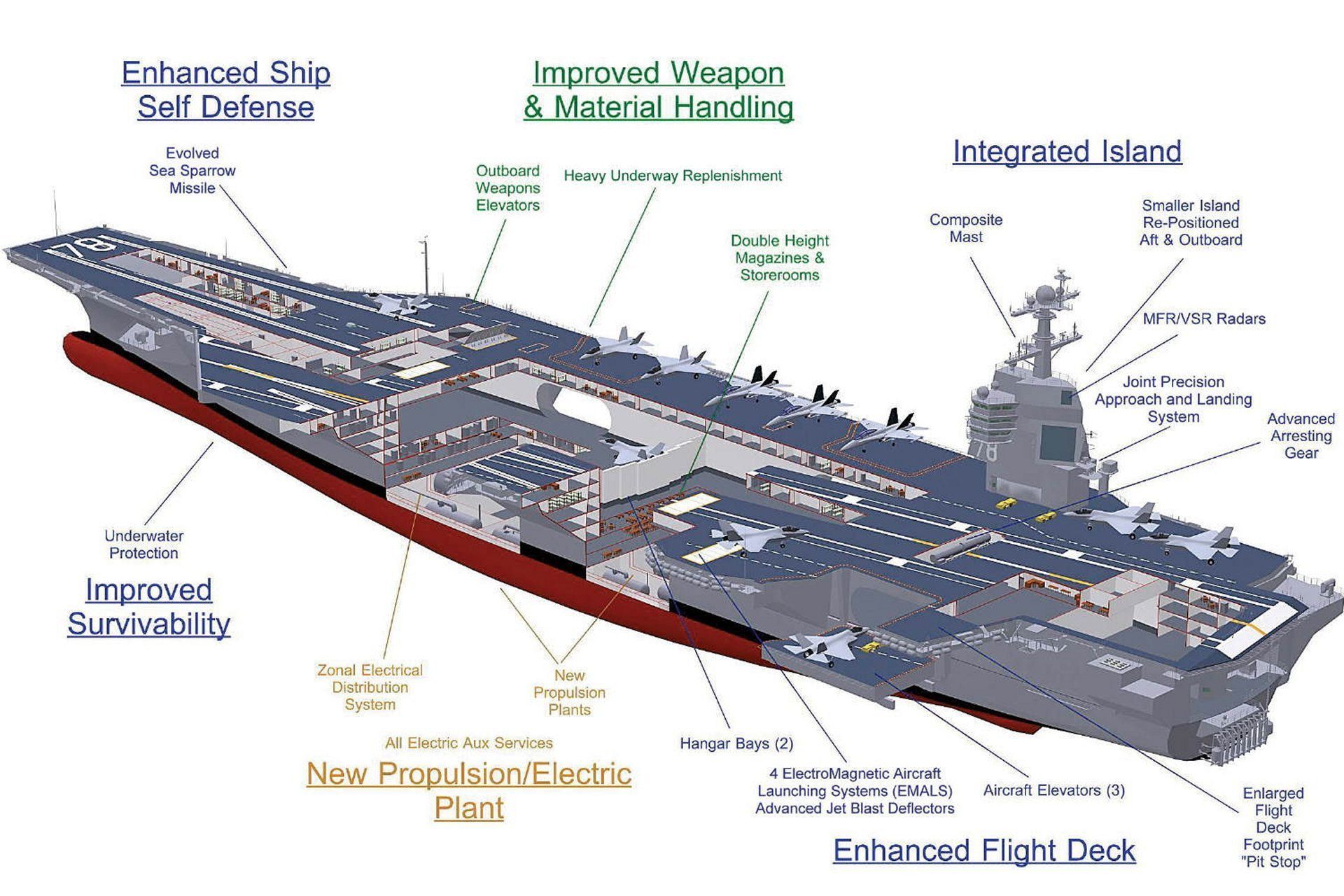

The USS Gerald R. Ford is the first is a series of new Ford-class carriers designed with a host of emerging technologies to address anticipated future threats and bring the power-projecting platform into the next century. The Ford class carriers are engineered with greater high-tech sensors and additional ship defensive technologies including missile interceptors and directed energy weapons, greater speed and maneuverability to avoid enemy fire and configurations which allow for more drones to launch from the deck of the ship. At the same time, the design is flexible enough to be adapted with new technologies for the future threats.

Ford’s entry into active service will once again raise the Navy’s carrier force to eleven ships. The Navy’s carrier fleet is unique in having a congressionally mandated minimum force level: U.S. Code § 5062 states, “the naval combat forces of the Navy shall include not less than 11 operational aircraft carriers.” For, now the Navy is operating with a waiver.

However, according to Capt. Brent Gaut, Ford’s executive officer, the next steps for the ship and her crew after commissioning will be to move into the test and evaluation phase. The ship is expected to set sail for a 10 to 12-day shakedown period where the crew will begin to test all of Ford’s systems including the EMALS and AAG. If all goes well, the ship will be certified to launch and recover aircraft. McCormack said. If all goes well, the ship should be operational by 2020. If the current schedule holds, Ford should be able to work up with an air wing and deploy in 2021 or 2022.

Ford Class Carrier Design

The Ford class is comparable to the Nimitz ships in size and weight, they measure 1,106 feet long versus the Nimitz’s 1,092 feet. Both classes weigh the same: approximately one hundred thousand tons fully loaded.

It has the ability to carry up to 90 aircraft, including the Boeing F/A-18E/F Super Hornet, Boeing EA-18G Growler, Grumman C-2 Greyhound, Northrop Grumman E-2 Hawkeye, Lockheed Martin F-35C Lightning II, Sikorsky SH-60 Seahawk helicopters, and unmanned combat aerial vehicles such as the Northrop Grumman X-47B. It has Stealth features to help reduce radar cross-section.

The ship is powered by two new-design AB1 nuclear reactors. The reactors are manufactured by Bechtel, which beat out longtime naval reactor giants General Electric and Westinghouse for the reactor contract. To power her systems and to meet future growth requirements, the two reactors create six hundred megawatts of electricity, triple the two hundred megawatts of the Nimitz class.

Ford is going to need that power, not only to reach its estimated top speed of thirty-plus knots but also the new Electromagnetic Aircraft Launch System (EMALS), which uses electric currents to generate strong magnetic fields that can quickly accelerate an aircraft to takeoff speeds. “Only half of the electrical power-generation capability on Ford Class is needed to run currently planned systems, including EMALS. CVN-78 will thus have the power reserves that the Nimitz class lacks to run lasers and dynamic armor.”

The US Navy aims to use modern equipment and extensive automation to reduce the crew size and the total cost of future aircraft carriers.The Ford — sitting now at Newport News Shipbuilding — will house about 2,600 sailors, 600 fewer than the Nimitz-class carriers. The Navy says that will save more than $4 billion over the ship’s 50-year lifespan. The air wing to support the Ford could add more personnel to the ship, which is designed to house more than 4,600 crew members.

The biggest visible difference from earlier supercarriers will be the more aft location of the island. Ships of the Ford class are intended to sustain 160 sorties per day for 30-plus days, with a surge capability of 270 sorties per day. Director of Operational Testing Michael Gilmore has criticized the assumptions used in these forecasts as unrealistic and has indicated sortie rates similar to the 120/240 per day of the Nimitz class would be acceptable.

The entire ship features far greater automation—with far greater reliance on electrical and electronic systems—than any other carrier in the fleet. Underneath, the massive steel deck, Ford is equipped with four Electromagnetic Aircraft Launch Systems (EMALS) and an Advanced Arresting Gear (AAG) which are replacing their steam and hydraulically driven equivalents onboard the Nimitz-class (and which allows for unrestricted operation of the #4 catapult). The ship also features 40 refueling stations and a revised configuration for her weapons elevators.

The new vessels have a hull similar to the Nimitz carriers, but introduce design features intended to improve efficiency and reduce operating costs, including reduced crew requirement. Each new technology and design feature integrated into the Ford-class aircraft carrier improves sortie generation, manning requirements, and operational capabilities. New defense systems, such as free-electron laser directed-energy weapons, dynamic armor, and tracking systems will require more power. The addition of new technologies, power systems, design layout, and better control systems results in an increased sortie rate of 25% over the Nimitz-class and a 25% reduction in manpower required to operate.

The Navy expects the Gerald R. Ford class will be part of the fleet for 90 years, until the year 2105, which means that the class must successfully accept new technology over the decades.

Technology

A1B Nuclear reactor

The new A1B reactor plant is a smaller, more efficient design that provides approximately three times the electrical power of the Nimitz-class A4W reactor plant. The modernization of the plant led to a higher core energy density, lower demands for pumping power, a simpler construction, and the use of modern electronic controls and displays. These changes resulted in a two-thirds reduction of watchstanding requirements and a significant decrease of required maintenance. The ship is powered by two Bechtel A1B nuclear reactors, each capable of producing 300 megawatts of electricity, triple that of Nimitz-class reactors.

Anchor room and hangar bay

The Ford weighs close to 100,000 tons and getting it to rest dead in the water requires some serious stopping power. Hours of planning go into dropping anchor, but when the brake is released and the anchor starts to drop, it happens fast: 90 feet of chain can pay out in 5 seconds.

Electromagnetic Aircraft Launch System (EMALS)

The vessel includes electromagnetic launch systems for jets and drones, replacing steam catapults; a smaller island that sits farther back on the ship, making it easier and quicker to refuel, re-arm and relaunch planes; and a nuclear power plant designed to allow cruising speeds of more than 30 knots and operation for 20 years without refueling.

The Electromagnetic Aircraft Launch System (EMALS) is more efficient, smaller, lighter, more powerful, and easier to control. The system is touted as easier on aircraft, extending their service lives, easier to maintain in general and capable of generating up to 25 percent more sorties than the older steam catapult system.

https://www.youtube.com/watch?v=dxMGj7tksa8&list=PLrl_d-N5C9D6S81_hdx6lQEy0pwAKVZsp

Increased control means that EMALS will be able to launch both heavier and lighter aircraft than the steam catapult. Also, the use of a controlled force will reduce the stress on airframes, resulting in less maintenance and a longer lifetime for the airframe. The power limitations for the Nimitz class make the installation of the recently developed EMALS impossible. EMALS was tested in June 2015.

Advanced Arresting Gear landing system

Electromagnetics will also be used in the new Advanced Arresting Gear (AAG) system. The AAG is designed for a broader range of aircraft, including UAVs, while reducing manpower and maintenance. Rotary engines which use simple energy-absorbing water turbines (or twisters) coupled to a large induction motor provide finer control of the arresting forces.By using electromagnetics the energy absorption is controlled by a turbo-electric engine. This makes the trap smoother and reduces shock on airframes.

The major systems that make up typical arresting gear are the hook cable or pendants, purchase cables or tapes, sheaves and arresting engines. Ford class carriers shall have three arresting cables laid across the landing area.

The current system relies on hydraulics to slow and stop a landing aircraft. While the hydraulic system is effective, as demonstrated by more than fifty years of implementation, the AAG system offers a number of improvements. The current system is unable to capture UAVs without damaging them due to extreme stresses on the airframe. UAVs do not have the necessary mass to drive the large hydraulic piston used to trap heavier, manned airplanes. Even though the system will look the same from the flight deck as its predecessor, it will be more flexible, safe, and reliable, and will require less maintenance and manning.

The AAG is being developed by General Atomics. In Jan 2020, General Atomics Electromagnetic Systems (GA-EMS) announced that High Cycle Testing of its Advanced Arresting Gear (AAG) system for Ford-class aircraft carriers was completed over a two-day period. High Cycle Testing was conducted on a single AAG system that is identical to the three systems aboard the USS Gerald R. Ford. Five F/A-18E/F Super Hornets were involved in the testing to simulate the operational tempo of carrier flight operations at sea. AAG is a turbo-electric system designed for controlled and reliable deceleration of aircraft. High Cycle Testing is part of the verification and validation of AAG System requirements. The AAG system test program has completed more than 5,000 arrestments at the land-based test facilities and 747 arrestments aboard CVN 78 during the ship’s initial sea trials, according to the company.

Sensors and self-defense systems

Ford will also have the most modern radar systems in the fleet by Raytheon, an integrated Active electronically scanned array search and tracking radar system. The Ford will have the new Dual Band Radar, which combines both the X-Band AN/SPY-3 Aegis radar and the S-Band Volume Surveillance Radar, distributed into three phased arrays. DBR is capable of search, track and multiple missile illumination, detecting enemy aircraft and missiles and then guiding Evolved Sea Sparrow Missiles (ESSM) to intercept. The island can be kept smaller by replacing six to ten radar antennas with a single six-faced radar.

The three faces dedicated to the X-band radar are responsible for low altitude tracking and radar illumination, while the other three faces dedicated to the S-band are responsible for target search and tracking regardless of weather. “Operating simultaneously over two electromagnetic frequency ranges, the DBR marks the first time this functionality has been achieved using two frequencies coordinated by a single resource manager. This new system has no moving parts, therefore minimizing maintenance and manning requirements for operation.

For self-defense, Ford will have two Mk. 29 missile launchers with eight ESSM each, and two Rolling Airframe Missile launchers. Raytheon Evolved Sea Sparrow missile (ESSM), defends against high-speed, highly maneuverable anti-ship missiles.It will also have four Phalanx Close-In Weapon Systems for point defense against aircraft, missiles and small ships, and four M2 .50 caliber machine guns. The close-in weapon system is the rolling airframe missile (RAM) from Raytheon and Ramsys GmbH.

Free Electron laser

The Navy is actively developing a weapon system called the free-electron laser (FEL) to address the cruise missile threat and the swarm-boat threat against Ford-class carriers. An FEL uses an electron gun to generate a stream of electrons. The electrons are then sent into a linear particle accelerator to accelerate them to near light speeds.

The accelerated electrons are then sent into a device, known informally as a wiggler, that exposes the electrons to a transverse magnetic field, which causes the electrons to “wiggle” from side to side and release some of their energy in the form of light (photons). The photons are then bounced between mirrors and emitted as a coherent beam of laser light. To increase the efficiency of the system, some of the electrons are then cycled back to the front of the particle accelerator via an energy recovery loop. The cost to fire one round from an FEL is about $1 and consumes about 10 MW of electricity.

RIM-162 Evolved SeaSparrow Missile (ESSM)

The RIM-162 Evolved SeaSparrow Missile (ESSM) is a development of the RIM-7 Sea Sparrow missile used to protect ships from attacking missiles and aircraft. ESSM is designed to counter supersonic maneuvering anti-ship missiles. ESSM also has the ability to be “quad-packed” in the Mark 41 Vertical Launch System system, allowing up to four ESSMs to be carried in a single cell.

Compared to the Sea Sparrow, ESSM has a larger, more powerful rocket motor for increased range and agility, as well as upgraded aerodynamics using strakes and skid-to-turn. In addition, ESSM takes advantage of the latest missile guidance technology, with different versions for Aegis/AN/SPY-1, Sewaco/Active Phased Array Radar (APAR), and traditional target illumination all-the-way. ESSM Block II will leverage existing technology and features a dual-mode X-band seeker, increased maneuverability, and other enhancements. Unlike Block 1, Block 2’s active seeker will support terminal engagement without the launch ship’s target illumination radars. The improved ESSM Block II will be fielded by the US Navy from 2020

AN/SPY-3 Radar

The AN/SPY-3 consists of three active arrays and the Receiver/Exciter (REX) cabinets abovedecks and the Signal and Data Processor (SDP) subsystem below-decks. The VSR has a similar architecture, with the beamforming and narrowband down-conversion functionality occurring in two additional cabinets per array. A central controller (the resource manager) resides in the Data Processor (DP). The DBR is the first radar system that uses a central controller and two active-array radars operating at different frequencies. The DBR gets its power from the Common Array Power System (CAPS), which comprises Power Conversion Units (PCUs) and Power Distribution Units (PDUs). The DBR is cooled via a closed-loop cooling system called the Common Array Cooling System (CACS).

The REX consists of a digital and an analog portion. The digital portion of the REX provides system-level timing and control. The analog portion contains the exciter and the receiver. The exciter is a low-amplitude and phase noise system that uses direct frequency synthesis. The radar’s noise characteristics support the high clutter cancellation requirements required in the broad range of maritime operating environments that DBR will likely encounter. The direct frequency synthesis allows a wide range of pulse repetition frequencies, pulse widths, and modulation schemes to be created.

The receiver has high dynamic range to support high clutter levels caused by close returns from range-ambiguous Doppler effect waveforms. The receiver has both narrowband and wideband channels, as well as multichannel capabilities to support monopulse radar processing and sidelobe blanking. The receiver generates digital data and sends the data to the signal processors.

The DBR uses IBM commercial off-the-shelf (COTS) supercomputers to provide control and signal processing. DBR is the first radar system to use COTS systems to perform the signal processing. Using COTS systems reduces development costs and increases system reliability and maintainability.

The high-performance COTS servers perform signal analysis using radar and digital signal processing techniques, including channel equalization, clutter filtering, Doppler processing, impulse editing, and implementation of a variety of advanced electronic protect algorithms. The IBM supercomputers are installed in cabinets that provide shock and vibration isolation. The DP contains the resource manager, the tracker, and the command and control processor, which processes commands from the combat system.

The DBR utilizes a multitier, dual-band tracker, which consists of a local X band tracker, a local S band tracker, and a central tracker. The central tracker merges the local tracker data together and directs the individual-band trackers’ updates. The X band tracker is optimized for low latency to support its mission of providing defense against fast, low-flying missiles, while the VSR tracker is optimized for throughput due to the large-volume search area coverage requirements.

The combat system develops doctrine-based response recommendations based on the current tactical situation and sends the recommendations to the DBR. The combat system also has control of which modes the radar will perform. Unlike previous-generation radars, the DBR does not require an operator and has no manned display consoles. The system uses information about the current environment and doctrine from the combat system to make automated decisions, not only reducing reaction times, but also reducing the risks associated with human error. The only human interaction is for maintenance and repair activities.

The Enterprise Air Surveillance Radar (EASR) is a new design surveillance radar that is to be installed in the second Gerald R. Ford-class aircraft carrier, John F. Kennedy, in lieu of the Dual Band radar. The America-class amphibious assault ships starting with LHA-8 and the planned LX(R) will also have this radar. The EASR suite’s initial per-unit cost will be about $180 million less than the DBR, for which the estimate is about $500 million.

Problems Delays and challenges

USS Ford, has had many problems, delays, and cost overruns due, mainly, to the Navy’s use of concurrency in attempting to develop new technologies at the same time as production. Ford has been under severe criticism. “The Ford is a poster child for how you don’t build a ship,” says Ray Mabus. He was former Secretary of the Navy during the Obama administration. “They were designing the Ford while they were building it — not a good way to build a ship,” Mabus says. “This is just a dumb way to build any type of ship, particularly something as big and complicated as a carrier.” “Not only did the price go through the roof, but the schedule just became terrible because there were so many new technologies, because it was so unproven and it wasn’t completely designed,” Mabus says.

The EMALS launch system and the Advanced Arresting Gear (AAG) have been two notable failures. Poor or unknown reliability of the newly designed catapults, arresting gear, weapons elevators, and radar, which are all critical for flight operations, could affect the ability of (the carrier) to generate sorties, making the ship more vulnerable to attack, or create limitations during routine operations,” the Director, Operational Test and Evaluation, or DTOE, report states.

However, Capt. Rick McCormack, Ford’s commanding officer, said that the ship has already tested the EMALS and AAG with dead loads, and as such, he is very confident that the systems will work as advertised. Navy is confident that they shall meet operational standards at sea.“I’m very very confident that the EMALS will do everything we need it to,” McCormack said.

However, there is another new technology that has been just as problem plagued but has not received as much attention – the ship’s Advanced Weapons Elevators (AWE). These elevators are used on carriers to move munitions from the ship’s magazines to the flight deck and handling areas for subsequent loading onto the aircraft. The elevators are quite small compared to the main aircraft elevators. Te Navy opted to abandon the well established elevators of the Nimitz class and, instead, develop a brand new electromagnetic elevator that works similar to the EMALS catapult system. As with the EMALS, development has been difficult and the Ford was delivered with non-functional elevators, all 11 of them.

In Feb 2018, DONALD Trump’s state-of-the-art supercarrier warship broke down while being chased by a 300ft-long Russian spy ship, a US Navy source claims. The newest and most expensive class of US aircraft carrier had problems with its steering while being pursued off the east coast of the US, a source close to the Navy told Daily Star Online. It is understood the USS Cole was prompted to get in between the Ford and the Russian ship, whose crew has access to anti-aircraft missiles and turret cannons for last-resort self-defence.

References and Resources also include:

- http://phys.org/news/2016-11-129b-acres-navy-next-generation-aircraft.html

- https://en.wikipedia.org/wiki/A1B_reactor

- http://nationalinterest.org/blog/the-buzz/the-us-navy-planning-big-changes-americas-future-aircraft-17762

- http://www.cbsnews.com/news/uss-gerald-r-ford-poster-child-for-how-you-dont-build-a-ship-says-former-navy-secretary/

- https://navy-matters.blogspot.com/2018/09/uss-ford-ups-and-downs.html

- https://www.youtube.com/watch?v=erU8fUuvIR8