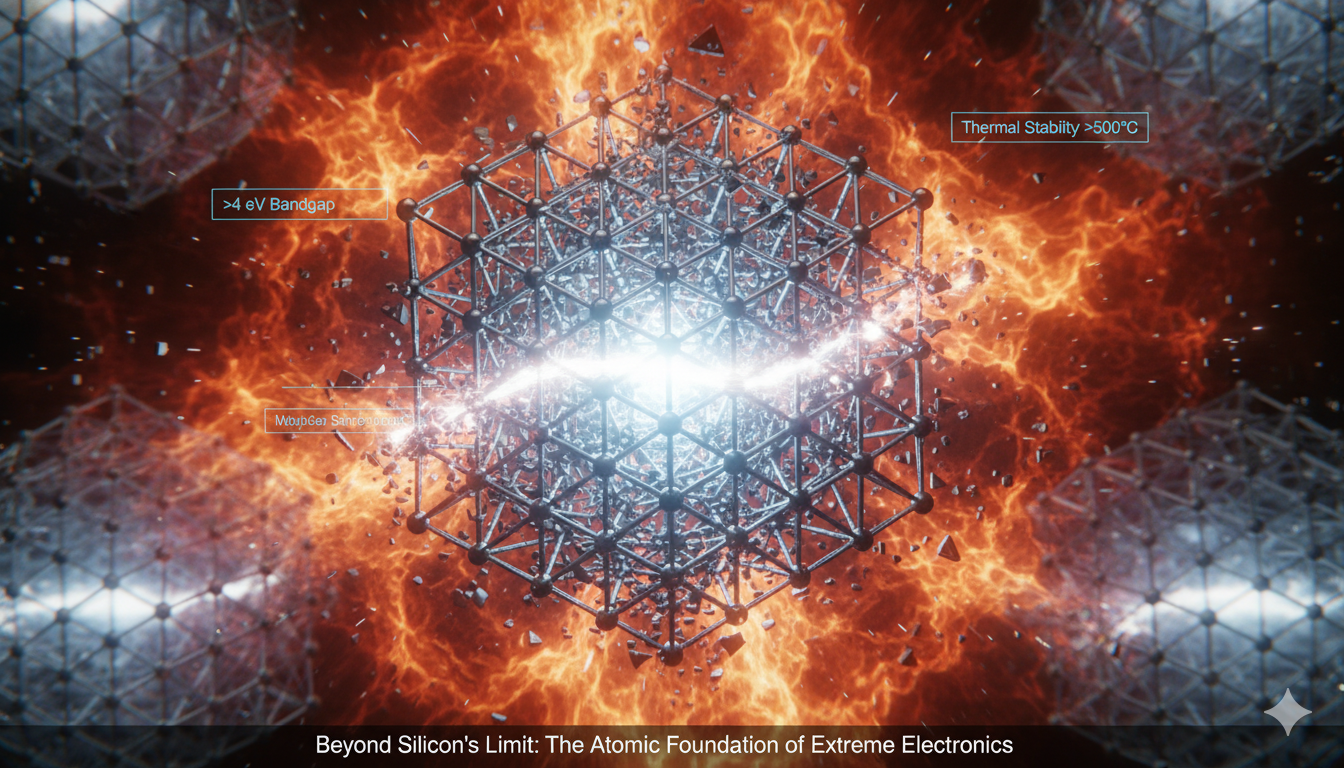

In the world of microelectronics, efficiency is everything. From data centers and electric grids to radar systems and electric vehicles, the quest for smaller, faster, and more power-efficient devices has driven decades of innovation. Yet silicon—the workhorse of the semiconductor industry—is reaching its physical and performance limits. To break through these barriers, the Defense Advanced…