With the growing global concerns over climate change, scientists are looking for cleaner energy sources and other ways to minimize the carbon footprint in the world. A carbon footprint is the total amount of greenhouse gas emissions that come from the production, use and end-of-life of a product or service. It is expected that in the next few decades there will be a major transformation in the materials used in civilian and military applications or in the aeronautics, automobile and other industries, and there will be a need to use materials and products that are more environmentally friendly.

Over several years, fiber-reinforced composites have been attracting great interest because of their many superior properties and applications. The well-known fact is that the reinforcement of fibers in different polymers significantly increases the mechanical properties of the composites. Generally, aircraft and automobile industries prefer to use synthetic fibers such as glass and carbon fibers for reinforcement in polymers. In addition, the increasing performance of composites has been identified by advanced research with two or three polymers/reinforcements or fillers. However, the recycling of these composites is difficult due to difficulty for separation of their components. On the other side, these composites cause severe environment issues during the landfills or burning. Most of these composites are made from petroleum-based nonrenewable resources.

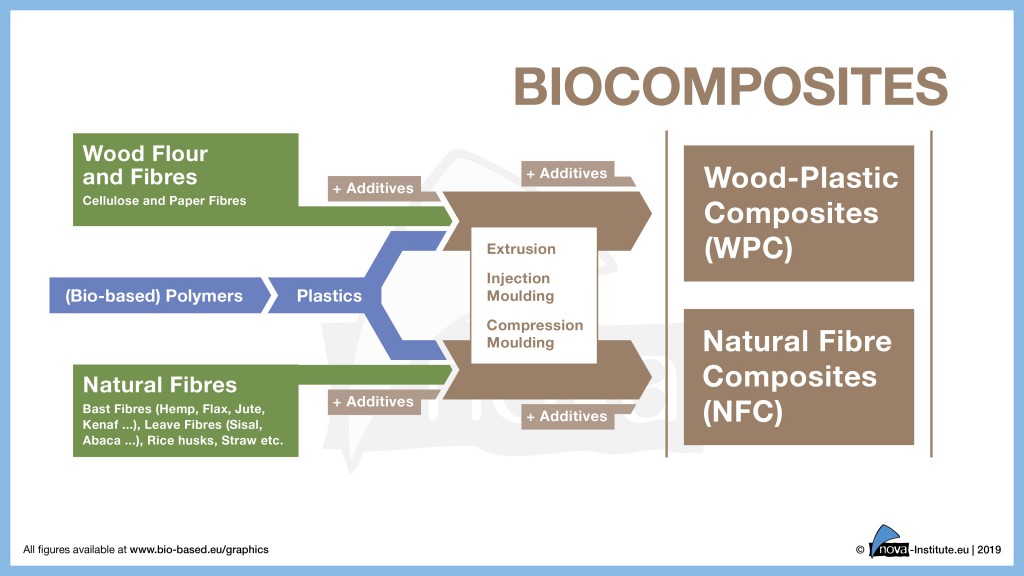

In order to replace the petroleum-based nonrenewable resource-based composites, the eco-friendly biocomposites need to reduce environmental impact. A biocomposite is a composite material formed by a matrix (resin) and a reinforcement of natural fibers. Environmental concern and cost of synthetic fibres have led the foundation of using natural fibre as reinforcement in polymeric composites.

The matrix phase is formed by polymers derived from renewable and nonrenewable resources. The matrix is important to protect the fibers from environmental degradation and mechanical damage, to hold the fibers together and to transfer the loads on it. In addition, biofibers are the principal components of biocomposites, which are derived from biological origins, for example fibers from crops (cotton, flax or hemp), recycled wood, waste paper, crop processing byproducts or regenerated cellulose fiber (viscose/rayon).

The reinforcements (cotton, hemp, flax, sisal, jute, and kenaf or recycled wood and paper) and biopolymers (natural biopolymers such as gelatin, corn zein and soy protein; synthetic biopolymers such as poly(lactic acid) (PLA), poly(vinyl alcohol) (PVA); and other microbial fermentation such as microbial polyesters) are renewable and degradable

Development of polymer biocomposites using natural fibers or wood particles as the reinforcing components is gaining increasing attention since synthetic fibers are expensive, non-biodegradable and their production is energy consuming, with the attendant negative impact on the environment. The use of wood fibers and wood flours as reinforcement in thermoplastics have been intensified due to their several advantages over the traditional synthetic fibers like glass, carbon and Kevlar fibers. Reinforcing polymer with wood fiber or particles enables the development of innovative, lightweight, strong, and low-cost materials that can find application in different areas of engineering. Most importantly, natural fibres are renewable, recyclable and biodegradable materials, which are very crucial for environmental sustainability.

They can be used alone, or as a complement to standard materials, such as carbon fiber. “A significant market driver for high-volume applications is the potential to disassociate material costs from the fluctuating price of oil and energy,” El Mansori said. “In many cases biobased materials offer weight reduction, added functionality, e.g., damping (restraining of vibratory motion) or impact absorption, and occupational health benefits.” Advocates of biocomposites state that use of these materials improve health and safety in their production, are lighter in weight, have a visual appeal similar to that of wood, and are environmentally superior

Biocomposites are rapidly emerging in industrial applications (automobiles, railway coach, aerospace, military applications, construction, and packaging) and fundamental research, due to its great benefits (renewable, cheap, recyclable, and biodegradable).

Chonta palm (Bactris gasipaes), also called pupunha palm, peach palm, or heart palm has origin in the tropical Latin American regions (Amazonia). Peach palm fruits are used in great proportion as food and oil products. Chonta wood palm is believed to be one of the hardest woods in the Amazonia for its strong and durable fibers and they can be used to make crafts, building parts, and weapons for hunting and fishing. Because of these properties, chonta palm fibers or wood particles offers innovative resource for reinforcement for polymer matrix composites. For example, heart palm residues have been used to build agglomerate and plywood panels, chopped fibers and polyurethane resins were mixed in a plywood mold, resulting in panels that can meet the ANSI 208.1 standard for flexural strength of particle boards

Classification

Biocomposites are divided into non-wood fibers and wood fibers, all of which present cellulose and lignin. The non-wood fibers (natural fibers) are more attractive for the industry due to the physical and mechanical properties which they present. Also, these fibers are relatively long fibers, and present high cellulose content, which delivers a high tensile strength, and degree of cellulose crystallinity, whereas natural fibers have some disadvantages because they have hydroxyl groups (OH) in the fiber that can attract water molecules, and thus, the fiber might swell. This results in voids at the interface of the composite, which will affect the mechanical properties and loss in dimensional stability. The wood fibers have this name because almost than 60% of its mass is wood elements. It presents softwood fibers (long and flexible) and hardwood fibers (shorter and stiffer), and has low degree of cellulose crystallinity.

Japan is developing wooden satellites to send into orbit by 2023 to cut down on space junk

Kyoto University is teaming up with a Japanese forestry company, Sumitomo Forestry, to develop wooden satellites to shoot into orbit by 2023 in an effort to cut down on space junk.Doi added that “eventually it will affect the environment of the Earth.”

“We are very concerned with the fact that all the satellites which re-enter the Earth’s atmosphere burn and create tiny alumina particles which will float in the upper atmosphere for many years,” explains Kyoto University professor Takao Doi, who took a trip to the International Space Station in 2008. “Eventually it will affect the environment of the Earth.”

At this point their ambitious program is still in the conceptual phase and scientists are exploring which varieties of wood might endure the harsh conditions of space, which include violent temperature fluctuations and radiation bombardment. The team’s preliminary investigation into the feasibility of their invention is being heavily guarded at this point and their intended methods are being kept secret.

So maybe this isn’t such an outlandish idea after all. Wood is an extremely durable material comprised of a pair of super-strong organic polymers called cellulose and lignin. Scientists have had success in the past by physically altering and chemically treating wood to boost its compositional strength as well, with some experiments discovering that wood can be even stronger than aluminum.

“The next stage will be developing the engineering model of the satellite, then we will manufacture the flight model,” Professor Doi added, noting that the first model would be ready for launch in 2023.

The partnership between Texas A&M Engineering and the Ecole Nationale Superieure d’Arts et Métiers aims to effect change to the global manufacturing industry.

Dr. Satish Bukkapatnam, director of the Texas A&M Engineering Experiment Station’s (TEES) Institute for Manufacturing Systems, and Dr. Mohamed El Mansori, professor in the Department of Mechanical, Materials Science and Manufacturing Engineering at ENSAM, combined their complementary strengths to advance the science and technology for biocomposite manufacturing to form the AM² transatlantic partnership. This partnership aims to effect change to a global manufacturing industry through extensive research collaborations, education programs, and mutual faculty and student exchange initiatives.

A biocomposite is a composite material formed by a matrix (resin) and a reinforcement of natural fibers. The matrix phase is formed by polymers derived from renewable and nonrenewable resources. Hemp, cotton, jute and flax are some common natural fiber reinforcements in biocomposites that have good mechanical properties. “The work with Professor El Mansori was initiated to adapt methods for studying the machining process to create precisely shaped slabs of natural fiber composite materials for the emerging industrial applications,” said Bukkapatnam.

In 2017 they combined their collaborative strengths: Texas A&M in smart manufacturing, focusing on advanced in situ sensing, and ENSAM’s strengths in multi-scale modeling and analysis, which led to several outcomes. First was the creation of a smart experimental setup to study forces, vibrations and acoustic emissions generated during the machining of natural-fiber composite materials, and thereby using the signal patterns themselves to understand the physical phenomena underlying the way the material is removed from the surface of the composite material during the cutting process. This guided the setting of the various conditions such as the speed at which the tool should move the cut, the best orientation of the composite material to achieve an efficient cut and quality products. The work also led to the development of mathematical, finite element models to simulate how forces are generated during the cutting process and how they vary under the influence of the heat generated during the process.

El Mansori said biocomposites, especially those with long continuous fibers, present many challenges during near net-shape processing, where requirements include accurate dimensional tolerancing, drilling holes for assembly and controlled surface characteristics. Finishing operations such as machining or polishing are mandatory for fabricating the biocomposite part to meet service requirements.

However, finishing operations should not cause excessive damage in order to preserve the required industrial functionality of the biocomposite part (i.e., mechanical, frictional, thermal, acoustic or damping properties). The main damage source emanates from the severe contact between the abrasive tools and the biocomposite due to the high-generated tribological and thermal stresses. Addressing these challenges required expertise in multiple areas.

“Understanding the mechanism of the cutting process is essential for creating quality products, especially those of interest to the automotive industry,” Bukkapatnam said. “Besides the two of us, this research effort brought together the expertise of Drs. J.N. Reddy and Bruce Tai of mechanical engineering (at Texas A&M), and two project associates, Drs. Zimo Wang and Faissal Chegdani, who have since graduated and now serve as assistant professors in SUNY Binghamton, U.S. and Arts et Métiers, France, respectively.” Because of the wide range of applications that exist for these natural composites, the impact of their research on cutting techniques can be enormous.

“Combinations of natural fibers and biobased polymers have been shown to have appealing composite properties, offering the enticing prospect that fully biobased composites are an increasing commercial reality,” El Mansori said. “Green image, weight savings, shorter cycle times, scratch resistance and above all, a lower (carbon) footprint are important factors for this development.”

Plus, the demand from designers, manufacturers and consumers for environmentally friendly products will inevitably drive the rapid development of other biocomposite materials and products as well. And future developments in fully biobased composites of consistent quality natural-fiber products could also be required at an affordable price in appropriate forms for composite molding and secondary mechanical processing technology.

“The next few decades will witness a major transformation in the materials that we use in our daily lives and for various applications,” Bukkapatnam said. “There will be a major push toward using materials and products that use a minimal carbon and economic footprint, and are environmentally benign. This research leverages Texas A&M’s initiatives in smart manufacturing to lead a major thrust toward smart, secure and sustainable manufacturing systems. These efforts are central to the current transatlantic partnership led by Texas A&M and Arts et Métiers.”

Biocomposite Market

The Global Biocomposites Market is expected to grow from USD 23,969.22 Million in 2019 to USD 41,532.60 Million by the end of 2025 at a Compound Annual Growth Rate (CAGR) of 9.59%

Increasing use of biocomposites in end-use sectors such as automotive, building and construction, electrical and electronics, and consumer goods is the main driver triggering the biocomposites market. Additionally, changing consumer preference from plastic composites to eco-friendly biocomposites is expected to spur market growth over the forecast period.

The handling of plastic waste globally is a serious issue as plastic products do not decompose easily. In order to tackle this problem, a number of governments have banned plastic products and are promoting the use of biocomposites as a substitute for plastic composites. Furthermore, they are used as a substitute for metal and alloys in automotive nonstructural parts such as parcel shelves and interior panels. The use of biocomposites in the automotive sector is likely to help in decreasing the overall weight of a vehicle and also reduce instances of injuries to passengers in cases of accidents. Similarly, surging demand in electrical and consumer durables sectors is expected to drive the market.

Biocomposites are one of the primary materials which are used in the automotive industry as they offer weight reduction, anti-damping, and impact absorption properties. The growing demand for lightweight vehicles, coupled with the increase in demand for electric cars across the globe is further expected to boost the global biocomposites market in the forecast period. For instance, Toyota Raum has its interior parts made by hemp fibers, and its springboard made from potato-derived PLA reinforced with sugarcane bagasse. The surging demand for biocomposites is also augmented towards its rapid growth across other end-use industries such as construction, electronics, consumer goods, and others.

Global Bio-Composites Market, by End-Use Industry

In terms of end-use industry, the transportation segment is the largest end-use industry for bio-composites in 2020 and is anticipated to remain so till the forecast period. Bio-composites are mainly used to make various automotive interior and exterior components in a vehicle. Bio composite-based auto parts and components are generally lightweight as compared to the competing metal elements and so, are gaining popularity in the marketplace for replacing metal auto parts and components to reduce the vehicle weight. Lightweight vehicles consume less fuel, which lowers CO2 emission and improves vehicle performance.

Global Bio-Composites Market, by Fiber Type

In terms of fiber type, the wood fiber type has captured the largest market share in 2020 and is anticipated to remain the largest segment till the forecast period. These fibers are widely available across regions and are of comparatively low cost. They are widely used in making various products and components for transportation and building & construction end-use industry.

Global Bio-Composites Market, by Process

In terms of process, the extrusion process is leading among other processes in the global bi-composites market in 2020. The extrusion process has the ability to provide complex cross-sectional products and components with superior finish, which are used in transportation, industrial, and building & construction end-use industries.

Global Bio-Composites Market, by Resin Type

In terms of resin type, the synthetic resin has captured approximately two third of the global bio-composites market in 2020 and is anticipated to remain the largest segment till the forecast period. Synthetic resin type bio-composites provide superior mechanical and physical properties and finishing, along with durability. These are mainly used in building & construction, aerospace & defense, and transportation end-use industries to make various products and components.

Global Bio-Composites Market, by Region:

Asia Pacific region is anticipated to grow with the highest CGAR of 22.3% during the forecast period till 2028. Asia-Pacific is projected as largest market of biocomposites due to demand in numerous end-use industry which includes building & construction, automotive, consumer goods, and others mainly in China which is followed by India, Japan, South Korea, and South-East Asian countries. Additionally, the region has undertaken the expansion of its infrastructural projects, which is anticipated to propel the demand for biocomposites in this region. In addition to construction, automobile industries in this region are fetching the maximum demand due to the growth of lightweight vehicles which provides better fuel efficiency and low carbon emission.

Asia-Pacific is trailed by North America, which is the second-largest region in the global biocomposites market. The growth of the market in this region is attributed to reconstruction activities and demand from the transportation sector coupled with the sports and aerospace industry. The primary application for biocomposite in the transportation sector in this region driven by aircraft manufacturers. Europe is another substantial market after North America in the global biocomposites market. The demand for the product in this region is majorly driven by the automotive industry and building & construction industry.

Latin America and the Middle East & Africa is expected to witness moderate growth in biocomposites market during the forecast period mainly due to applications of biocomposites in industries such as building & construction and automotive industry.

Some of the key players of global bio-composites market include UPM Biocomposites, Jelu-Werk J. Ehrler GmbH & Co. , Tecnaro GmbH, Trex Company, Inc, FlexForm Technologies , Green Bay Decking, Green Bay Decking, Yixing Hualong New Material Lumber Co., Ltd., Anhui Guofeng Wood-Plastic Composite Co., Ltd, Lingrove, TimberTech ,Fiberon, LLC, Universal Forest Products, Inc., Axion International, Inc., and others.

References and Resources also include:

https://www.syfy.com/syfywire/japanese-tech-firm-creating-the-worlds-first-wooden-satellites