Introduction:

The world of military technology is undergoing a profound transformation with the advent of High Power Fiber Lasers (HPFL). These lasers, harnessing the principles of “light amplification by the stimulated emission of radiation” (LASER), are at the forefront of innovation, enabling the development of Laser Directed Energy Weapons (LDEWs). This article explores the recent breakthroughs in HPFL technology and their implications for the deployment of advanced laser weaponry.

Understanding Lasers and Their Applications:

Laser, a device that stimulates atoms or molecules to emit light at particular wavelengths and amplifies that light, typically producing a very narrow beam of radiation. The emission generally covers an extremely limited range of visible, infrared, or ultraviolet wavelengths. Many different types of lasers have been developed, with highly varied characteristics. Laser is an acronym for “light amplification by the stimulated emission of radiation.”

Lasers deliver coherent, monochromatic, well-controlled, and precisely directed light beams. Most laser applications fall into one of a few broad categories: (1) transmission and processing of information, (2) precise delivery of energy, and (3) alignment, measurement, and imaging. These categories cover diverse applications, from pinpoint energy delivery for delicate surgery to heavy-duty welding and from the mundane alignment of suspended ceilings to laboratory measurements of atomic properties.

Scientists have shown that lasers can concentrate extremely high powers in either pulses or continuous beams. Major applications for these high-power levels are fusion research, nuclear weapons testing, and missile defense. Extremely high temperatures and pressures are needed to force atomic nuclei to fuse together, releasing energy. In the 1960s physicists at the Lawrence Livermore National Laboratory in California calculated that intense laser pulses could produce those conditions by heating and compressing tiny pellets containing mixtures of hydrogen isotopes.

Military Applications: Laser Directed Energy Weapons:

In the military arena, lasers have evolved into potent weapons known as Laser Directed Energy Weapons (DEWs). These weapons offer a range of advantages, including high precision, rapid on-target effects, scalability, minimal collateral damage, low logistics overhead, and cost-effectiveness. The development of laser weapons has become a strategic focus for defense forces worldwide.

One of the earliest operational weapon was U.S. Navy’s Laser Weapon System (LaWS), a 33 kW system, successfully demonstrated its capabilities by shooting down an unmanned aerial vehicle. This system, utilizing six fiber lasers incoherently combined into one beam, highlights the adaptability and effectiveness of fiber lasers in real-world scenarios.

The development of laser weapons requires many critical technologies, first is development of lasers capable of generating powers in kilowatts to megawatts range to be able to produce useful damage effects on the target. Laser require a power of the order of 100 kW, to be employed as directed energy weapons, in varieties of missions such as wide-area, ground-based defense against rockets, artillery and mortars; precision strike missions for airborne platforms; and shipboard defense against cruise missiles. To destroy anti-ship cruise missiles would require a beam of 500 kilowatts and demand megawatts of power.

Chemical lasers are the only systems that have produced megawatt-level outputs, however, they require special handling because of toxic chemicals hence fallen out of favor. Another reason is that they rely on what is essentially an external/independent power source, and thus lack the key strategic value of directed energy weapons: a virtually unlimited magazine.

The push to optimize the size, weight and power (called SWaP in military parlance) of field deployed laser weapons has driven a progression in the technology of the gain material used from chemical (e.g. deuterium fluoride), to solid state, and, most recently, to fiber.

Three core technologies for generating high power lasers include:

Solid-state lasers. This could include slab and disk lasers which are currently used in battlefield targeting applications. The power level of solid-state laser technology offers a range of hundreds of kilowatts. DE lasers in the class of 100 kW to 1 MW are needed to pursue applications such as anti-cruise and ballistic missiles.

Solid state lasers are electrically powered, and they are separated into three types: Fiber solid-state lasers like LaWS, slab solid-state lasers, and free electron lasers. While they avoid the complicated logistics associated with chemical lasers, SSLs are generally not very efficient.

Fiber lasers. The fiber laser is a variation on the standard solid-state laser, with the medium being a clad fiber rather than a rod, a slab, or a disk and Laser light is emitted by a dopant in the central core of the fiber. While typically used in the commercial material processing industry, this laser technology dominates the lower end of the power scale offering 1kW to tens of kilowatts of power. However, the size and weight requirements make industrially engineered fiber lasers challenging to integrate into defense platforms.

Hybrid lasers. Diode-pumped alkali lasers are a prominent example of the new hybrid technology, which includes elements of both fiber and solid-state laser technologies. Hybrid technology strives to achieve megawatt power levels at size and weight targets compatible with airborne platforms.

All three types of directed energy laser technologies — fiber, solid-state or hybrid, have one thing in common —they are all optically pumped with a laser diode. Laser diodes offer an electrical-to-optical conversion efficiency over 60% and are easily scalable to MWs of power. This is an essential element for directed energy applications, as the increased power is needed to reduce the time the laser needs to be held on target and allows for effective targeting at an increased range.

The Rise of High Power Fiber Lasers:

Three core technologies drive high-power lasers: fiber lasers, solid-state lasers, and hybrid lasers. Fiber lasers, especially, have emerged as the most promising technology for directed energy weapons. Their advantages include high electrical-to-optical efficiency (40%), reliability in harsh military environments, and near diffraction-limited light output.

Fiber lasers utilize an optical fiber doped with rare-earth elements, confining photons within the fiber. This not only ensures stability but also simplifies beam delivery without requiring complex optical equipment. The choice of rare-earth dopants like ytterbium, erbium, and thulium allows for various output wavelengths, including eye-safe ranges.

Because a fiber laser generates its beam inside the core, delivery of the beam doesn’t require complex or sensitive optical equipment. A normal laser, on the other hand, either uses an optical fiber to move the laser beam or uses mirrors to bounce it around. Either approach works, but both require extremely precise alignment. That makes normal lasers sensitive to movement and impact. And once things go out of alignment, a specialist has to set things right. A fiber laser has no such sensitivity. It’s stable. A fiber laser can handle the bumps, knocks, vibrations and general discord of any assembly line.

Efficiency and Power Scalability:

Fiber lasers excel in power efficiency, converting nearly 100% of input into the beam. This minimizes heat generation, contributing to the lasers’ robustness and reducing maintenance requirements. Moreover, fiber lasers boast superior reliability, making them ideal for high-demand applications in military environments.

High Power Fiber Lasers have emerged as a game-changer, offering a unique set of advantages over traditional laser systems. Unlike their solid-state counterparts, fiber lasers utilize optical fibers as the gain medium, allowing for enhanced efficiency, flexibility, and scalability. The breakthrough lies in achieving unprecedented power levels with these fiber lasers, making them ideal candidates for directing energy in military applications.

Fiber laser Configurations

Continuous-wave fiber lasers can be either single- or multimode (in terms of transverse modes). A single mode produces a high-quality beam for materials working or sending a beam through the atmosphere, while multimode industrial lasers can generate higher raw power. If an application does not require the extremely high intensities resulting from singlemode operation, the higher total power from multimode operation is often an advantage—for example, for some kinds of cutting and welding, and particularly for heat-treating, where a large area is illuminated.

Long-pulse fiber lasers are essentially quasi-CW lasers, typically producing millisecond-type pulses. Typically they have a 10% duty cycle (resulting from the pump diode modulation). This results in higher peak powers than in CW operation—typically on the order of ten times higher. This can be an advantage for some kinds of materials working such as pulse drilling. The repetition rate can range up to 500 Hz, depending on the pulse duration.

Key differences among laser designs include:

- the nature of the gain media,

- how the gain media are energized (pumped),

- the design of the cavity,

- the inclusion of components to control the spectral, spatial, and temporal characteristics of the output beam,

- the optical system employed to deliver the laser beam to the application, and the coupling among these components.

The choices made by the laser designer among these technologies determine all of the important laser characteristics, including performance (power, efficiency, beam quality, wavelength, polarization, stability, etc.) and practicality (cost, reliability, manufacturability, serviceability, etc.), which ultimately determine the suitability of the laser source for the intended applications.

Three key technologies have been especially important for the development of high-performance, high-reliability lasers for industrial applications:

- Diode laser pump sources: Diode (semiconductor) lasers directly convert electrical energy to light with high efficiency (>50%). Continuous improvements, particularly during and after the telecommunications boom of the 1990s, have dramatically increased the power, efficiency, and reliability of diode lasers. Diode lasers are particularly well suited for pumping solid-state gain media because of their brightness and spectral characteristics. Diode lasers are manufactured in two formats: (a) single emitters, in which each semiconductor chip includes one light-producing region (emitter) that typically provides 10 – 20 W of power; and (b) diode bars, in which multiple emitters are included within one semiconductor structure. Single emitters were developed extensively for telecom (and the advances continue to this day); they provide the highest power, brightness, efficiency, modulation rate, and reliability (>1,000,000 hr. mean time to failure), in part because the emitters are thermally and electrically decoupled, and they can be efficiently coupled into an optical fiber.

- Solid-state gain media: Solid-state gain media are generally more reliable and require less maintenance and consumables than gaseous or liquid gain media. Most solid-state gain media are composed of a rare-earth element, which provides optical gain, doped into a crystalline or glass host. The choice of the rare-earth dopant(s) and host material determines the absorbing (pumping) and emitting (lasing) wavelengths and the efficiency, which in turn determine the attainable power and beam quality. Yb-doped gain media are particularly well suited for high-power applications because they are pumped at 910 – 980 nm, where diode lasers offer the highest power and efficiency, and lase in the wavelength range of 1030 – 1090 nm, where the small energy difference from the pump wavelength (“quantum defect”) enables operation at high optical-to-optical (pump-to-lasing) efficiency and correspondingly low thermal load.

- Optical fibers: An optical fiber is a strand of glass (typically silica-based) that guides light by total internal reflection, thereby eliminating the effects of diffraction. Confining a laser beam to a fiber enables low-loss transmission and delivery of optical power without the use of mirrors, lenses, or other free-space optics that are prone to misalignment, contamination, and damage and whose performance can be degraded by vibration, temperature variations, other environmental factors, and optical power changes. Passive optical fibers simply transmit light, whereas active optical fibers, in which the core is doped with a rare-earth element and pumped by a diode laser, provide gain. The fiber gain medium offers the highest optical-to-optical efficiency because of the long optical path length and excellent overlap of the lasing beam with the gain region. Furthermore, the high surface-area-to-volume ratio facilitates heat removal, making the fiber gain medium particularly well suited to power scaling. Finally, the mirrors required to form a laser cavity can be written into passive optical fiber (fiber Bragg gratings) and spliced to the gain fiber. As with pump diodes, advances in optical fibers have been driven by telecommunications applications and continue today.

The highest single-mode power available from a fiber laser is 10 kW, from IPG Photonics. In the system, a master oscillator produces a kilowatt of optical power that is fed into an amplifier stage pumped at 1018 nm with light from other fiber lasers. The entire laser system is about the size of two refrigerators. IPG’s High Power CW recent Fiber Lasers cover output power range from 1 kW to over 100 kW and feature a wide range of operating wavelengths, single-mode and multi-mode options, high stability and extremely long pump diode lifetime. These lasers are water-cooled and can be supplied with a built-in or standalone chiller. The lasers are available with a wide variety of fiber terminations, collimation optics and processing heads.

The highest multimode power reached is 50 kW, also by IPG Photonics. The system relies on incoherent beam combination, so it’s not a super high-quality beam (beam parameter product of 10, M2 of 33). This laser has been shipped around the country and has operated at 50 kilowatts in five states. This is the kind of durability that makes fiber lasers attractive for industry. Their primary use is in industrial materials working, a billion-dollar market for fiber lasers. Multimode fiber lasers can operate at continuous power levels to 100 kW because their larger cores spread the laser power through a larger volume, reducing the power density that contributes to nonlinear effects.

Q-switching is possible in fiber lasers, with the principle being the same as for bulk Q-switched lasers. Typical pulse lengths range from low nanosecond up to the microsecond range; the longer the fiber, the more time is needed to Q-switch the output, producing a longer pulse. Fiber properties impose some limitations on Q-switching. Nonlinearities are more severe in a fiber laser due to the core’s small cross-sectional area, so the peak power has to be somewhat limited. One can either use bulk Q-switches, giving higher performance, or a fiber Q-switch, which is spliced to the ends of the active part of the fiber laser.

The Q-switched pulses can be amplified in fiber or in bulk. An example of the latter is found at the National Ignition Facility (NIF; Livermore, CA), where a fiber laser is the master oscillator for the 192 beams of the NIF laser: Small pulses from the fiber laser are amplified up to megajoule size in large slabs of doped glass. Q-switched fiber lasers are used, for example, in pulsed materials working, such as laser marking or working semiconductor electronics. The are also used for lidar; a module green module about the size of one’s hand, contains an eye-safe erbium fiber laser with a 4 kW peak power, a 50 kHz repetition rate, and a 5-to-15-ns pulse duration.

In modelocked fiber lasers, the repetition rate depends on the length of the gain material, as in any kind of modelocking scheme, while pulse duration depends on the gain bandwidth. The shortest achievable oscillator pulses are in the 50 fs range, with more typical durations in the 100 fs range. Shorter pulses can be generated in oscillator-amplifier systems with external chirped-pulse amplification and subsequent pulse compression.

High Efficiency

Using a fiber as a laser medium gives a long interaction length, which works well for diode-pumping. This geometry results in high photon conversion efficiency, as well as a rugged and compact design. When fiber components are spliced together, there are no discrete optics to adjust or to get out of alignment.

Fiber lasers are quasi-three-level systems. A pump photon excites a transition from a ground state to an upper level; the laser transition is a drop from the lowest part of the upper level down into some of the split ground states. This is very efficient: For example, ytterbium with a pump photon at 940 nm produces an emitted photon at 1030 nm-a quantum defect (lost energy) of only about 9%

Overall fiber-laser efficiency is the result of a two-stage process. First is the efficiency of the pump diode. Semiconductor lasers are very efficient, with on the order of 50% electrical-to-optical efficiency. Laboratory results are even better, with 70% or even more of the electrical pump energy being converted into light. When this output is matched carefully to the fiber laser’s absorption line, the result is the pump efficiency. The second is the optical-to-optical conversion efficiency. With a small photon defect, high excitation and extraction efficiency can be achieved, producing an optical-to-optical conversion efficiency on the order of 60% to 70%. The result is a wall-plug efficiency in the 25% to 35% range.

In terms of SWaP optimization of pump diodes for laser weapons, a current benchmark is to achieve a weight to output power ratio of 1 kg/kW. Coherent | DILAS has developed several advances in diode laser technology to reach this goal, and, in fact, is already working on devices that will attain the next level of performance – 0.5 kg for 1 kW of output.

Existing lasers generally dissipate two-thirds to three-quarters of the energy as heat, requiring still-bulky cooling equipment to avoid overheating damage. Air cooling can yield an unacceptable delay between shots. A key factor for fiber lasers is that the fiber has a large surface-to-volume ratio so that heat can be dissipated relatively easily. Both solid state (e.g. slab and rod) and fiber lasers can be diode pumped, and diode power supplies and pump modules themselves are electrically efficient and lend themselves to miniaturization. This efficiency, in turn, reduces the cooling requirements, and all its attendant equipment (pumps, heat exchangers, etc.).

Fibre Laser technology

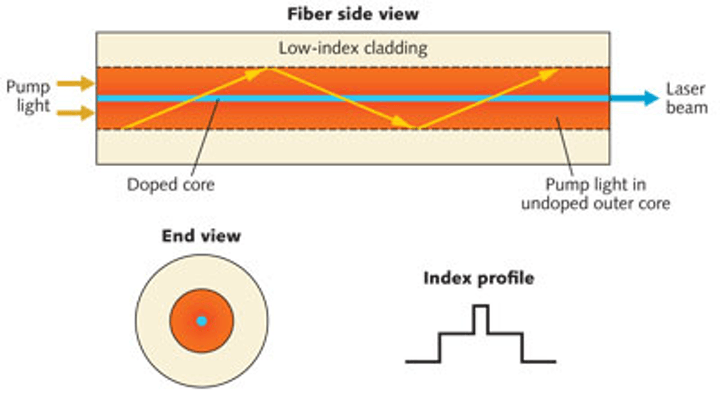

The most common geometry of the fiber used in fiber lasers is a dual-core structure. An undoped outer core (sometimes called an inner cladding) collects the pump light and guides it along the fiber. Stimulated emission generated in the fiber passes through the inner core, which often is singlemode. The inner core contains the dopant (ytterbium or erbium) that is stimulated to emit radiation by the pump light. The doped fiber has a cavity mirror on each end; in practice, these are fiber Bragg gratings, which can be fabricated within the fiber. Numerous noncircular variations exist on the shape of the outer core; these shapes, which include hexagonal, D-shaped, and rectangular, decrease the chances of the pump light missing the central core.

However, the fiber host is usually silica glass with a rare earth dopant in the core. The primary dopants are ytterbium and erbium. Ytterbium has center wavelengths ranging from about 1030 to 1080 nm and can emit in a broader range of wavelengths if pushed. Using pump diodes emitting in the 940 nm range can make the photon deficit very small. Ytterbium has none of the self-quenching effects that occur in neodymium at high densities, which is why neodymium is used in bulk lasers and ytterbium is used in fiber lasers (they both provide roughly the same wavelength).

Erbium fiber lasers emit at 1530 to 1620 nm, which is an eye-safe wavelength range. This can be frequency-doubled to generate light at 780 nm—a wavelength that’s not available from fiber lasers in other ways. And finally, ytterbium can be added to erbium so that the ytterbium absorbs pump light and transfers that energy to erbium. Thulium is another dopant that emits even deeper into the near-infrared (NIR; 1750 to 2100 nm), and is thus another eye-safe material

A fiber laser can be end- or side-pumped. In end-pumping, the light from one or many pump lasers is fired into the end of the fiber. In side-pumping, pump light is coupled into the side of the fiber; actually, it is fed into a coupler that couples it into the outer core.

Power limitations can arise, particularly from working within a singlemode fiber. Such a fiber core has a very small cross-sectional area, and as a result, very high-intensity light going through it. Nonlinear Brillouin scattering becomes increasingly important at these high intensities, and can limit output at multikilowatt levels. If the output is high enough, the fiber end can be optically damaged.

Another advantage is that fiber lasers are power efficient. A fiber laser can convert nearly 100 percent of the input it receives into the beam, thus limiting the amount of power that is converted into heat energy, That means the fiber tends to stay safe from heat damage or fracture. All of this adds up to a robust laser that requires next-to-no maintenance.

High power fiber lasers possess unique combination of properties that make them excel over conventional non-laser and competing laser technologies on both quality and cost:

- inherently higher brightness (high power and small spot size)

- Excellent beam quality: The beam quality is determined by the wave-guiding properties of the fiber and is extraordinarily stable, even in the presence of environmental perturbations and changes in optical power level. With suitable designs, fiber lasers can provide single-mode (diffraction-limited) beam quality, although this feature is not typically used for multi-kW industrial applications. The high beam quality of fiber lasers enables:

- superior reliability/ hot redundancy : A unique feature of fiber lasers is the ability to use fiber-based components and fusion splicing (melting together of the fibers) to completely eliminate free-space optics and their associated mounts and adjustments between the pump diodes and the process head. The optical beams are confined to a sealed, stable, alignment-free optical system that is impervious to vibration, contamination, power changes, etc. When pumped with single-emitter-based pumps with telecomgrade reliability, these fiber lasers have no consumables other than electricity and require no routine maintenance.

- wall-plug efficiency exceeding that of high brightness direct diode systems, typically achieving 30% and with the capability of 50%. In addition to reducing power consumption, high efficiency minimizes cooling requirements, further reducing power consumption, cost, and floor space required for the laser system.

- modularity and scalability allowing for easy maintenance and low down time

- fiber optic delivery with a wide choice of output fiber core diameters optimized for the application

- compact rugged design

- ease of integration with scanners and optical heads

- availability of beam switches, couplers and sharers providing unique versatility.

Key Technological Breakthroughs:

To overcome the limitations of single-mode fiber lasers, developers have ingeniously harnessed the power of multiple fiber lasers to generate high-intensity beams. Notably, Phillip Sprangle and colleagues at the U.S. Naval Research Laboratory explored incoherent beam combination, successfully combining beams from four fiber lasers to deliver a total of 5 kW to a target 3.2 km away. Their findings, indicating little difference in energy-on-target between coherently and incoherently combined laser beams over multi-kilometer propagation ranges and moderate to high turbulence, prompted the U.S. Office of Naval Research to acquire six 5.5-kW industrial fiber lasers from IPG. In the Navy LaWS (Laser Weapon System), these lasers were incoherently combined by directing their beams through a single telescope via different mirrors, mounted on the USS Ponce during its deployment to the Persian Gulf.

The success of this 33 kW system, comprised of easily-available components, was demonstrated when it effectively intercepted and brought down an unmanned aerial vehicle (UAV), showcasing the adaptability of fiber lasers to meet formidable power requirements.

Power Scalability: Recent advancements in HPFL technology have enabled significant increases in power scalability. Researchers have achieved record-breaking power levels, reaching into the kilowatt and even megawatt range. Researchers have successfully demonstrated HPFLs capable of delivering over 100 kW of continuous power, a significant milestone in the field. This breakthrough opens up possibilities for even more powerful LDEWs and industrial applications.

Fiber Optic Flexibility: The inherent flexibility of fiber optics allows for intricate beam control and manipulation. This characteristic proves invaluable in directing laser beams with precision, enabling military applications such as target tracking, engagement, and neutralization.

Improved Beam Quality: Enhancements in beam quality contribute to increased focus and accuracy. High beam quality ensures that the laser energy is concentrated over longer distances, making it an effective tool for military operations, including air and missile defense. Enhanced Advances in beam shaping and control techniques have led to the development of HPFLs with exceptional beam quality, enabling precise targeting and efficient energy delivery over longer distances.

Improved Efficiency: Researchers are continuously refining HPFL designs to achieve higher electrical-to-optical conversion efficiency, reducing energy consumption and improving overall system performance.

Compact and Robust Designs: HPFLs are becoming more compact and lightweight, making them suitable for integration into a wider range of platforms, from handheld devices to large-scale defense systems.

Efficient Cooling Systems: Overcoming the challenge of excess heat generation, modern HPFL systems incorporate efficient cooling mechanisms. This breakthrough ensures sustained high-power operation, making them reliable and capable of handling prolonged engagements.

Wavelength Diversity: The development of HPFLs operating in different wavelengths is expanding their applicability to various applications, such as material processing, biomedical treatments, and remote sensing.

Enhanced Reliability: HPFLs are becoming increasingly reliable and resistant to operational challenges, such as vibrations, extreme temperatures, and harsh environments.

Fiber-based Beam Combining: Researchers are exploring methods to combine multiple HPFLs into a single, high-power beam, further expanding the power capabilities of these lasers.

Integration with Advanced Control Systems: HPFLs are being integrated with sophisticated control systems that enable precise beam steering, modulation, and power control, enhancing their versatility and effectiveness.

Development of Novel Fiber Materials: Scientists are developing new fiber materials with improved properties, such as higher thermal conductivity and resistance to optical damage, to enhance the performance and longevity of HPFLs.

Exploration of Ultrashort Pulse HPFLs: Researchers are investigating the potential of ultrashort pulse HPFLs for high-precision applications in material processing, medicine, and scientific research.

Nano-Particles Enhancing Efficiency and Safety:

Researchers at the U.S. Naval Research Laboratory are pushing the boundaries by incorporating nano-particles into rare-earth-ion-doped fibers. This innovative approach has resulted in lasers with 85% efficiency at a 2-micron wavelength, considered eye-safe. The nano-particles not only enhance efficiency but also address challenges such as shielding rare-earth ions from silica and reducing light output degradation.

This innovative approach involves utilizing “rare-earth-ion-doped fiber,” wherein a silica fiber infused with holmium rare earth ions is pumped with laser light. Headed by Jas S. Sanghera, the Optical Materials and Devices Branch achieved an exceptional 85 percent efficiency with this method, crucial for developing high-energy, eye-safe lasers. By introducing a nano-particle ‘dopant,’ the team mitigated energy losses during the lasing process, reaching 85 percent efficiency at a 2-micron wavelength, deemed “eye-safer” than the traditional 1 micron.

This nano-particle doping not only addresses safety concerns related to scattered light but also resolves issues like shielding rare earth ions from silica interference and preventing ion clustering, optimizing light output. The ingenious chemistry involved, dissolving holmium in a cost-effective nano-powder, facilitates the creation of a suitable crystal environment for the rare earth ions. The resulting specialty fiber laser, synthesized using a low-cost process akin to making telecom fiber, holds promise for applications in defense, telecommunications, and precision tasks like welding and laser-cutting. A patent application for this transformative process has already been submitted, marking a significant leap in advancing laser technology for diverse commercial uses.

Applications of Laser Directed Energy Weapons:

Precision Targeting: Laser weapons offer unparalleled precision in targeting, minimizing collateral damage and reducing the risk of civilian casualties. High Power Fiber Lasers enhance this capability by providing a stable and focused energy beam.

Anti-Drone Defense: Unmanned Aerial Vehicles (UAVs) pose a growing threat in modern warfare. HPFL technology allows for rapid and precise targeting of drones, providing an effective defense against these airborne threats.

Missile Defense: Laser Directed Energy Weapons have the potential to revolutionize missile defense systems. The speed of light enables rapid target engagement, making it possible to intercept and neutralize incoming missiles with unprecedented speed and accuracy.

Shipborne Defense Systems: Integrating HPFL technology into naval defense systems enhances maritime security. Laser weapons can be used for ship self-defense against aerial threats, creating a dynamic and adaptive defense strategy.

T-Bar Laser Design

The T-Bar construction, short for “tailored bar,” represents a significant advancement in laser design, particularly in achieving the SWaP benchmark. Coherent | DILAS has introduced this innovative approach to combine the high total output power of traditional diode laser bars with the more relaxed cooling requirements of single emitters. The fundamental unit of the T-Bar is a diode laser mini-bar containing five emitters on a single, 5 mm wide substrate, producing approximately 50 W in total.

For military applications, four T-Bar dies are mounted onto a single substrate, resulting in a total of 20 emitters. Up to four of these substrates are then vertically stacked, creating a compact assembly with 80 individual emitters and a total output of around 800 W. The key optical feature of the T-Bar design lies in its wide emitter spacing, low divergence, and relatively low beam parameter product, allowing efficient colinearization of light from all 80 emitters. This light is then coupled into a single 225 μm core fiber with a numerical aperture of only 0.22, maximizing output power per unit volume.

The T-Bar’s larger emitter spacing significantly reduces thermal crosstalk, relaxing cooling requirements. Coherent | DILAS has introduced a “macrochannel” cooler, utilizing larger bore channels, allowing the use of less strictly filtered tap water and eliminating the need for high-pressure pumping. The reduced cooling demand enables the laser bar to be placed on a submount, avoiding direct electrical contact with the cooler and eliminating the need for deionized water.

Fiber Laser Market Overview:

The global fiber laser market was valued at $3.3 billion in 2022, and is projected to reach $9.2 billion by 2032, growing at a CAGR of 11% from 2023 to 2032.

Enhanced productivity is a key driver, with industries such as aerospace and defense, consumer electronics, healthcare, industrial, and manufacturing adopting fiber lasers for increased efficiency.

Fiber laser cutting systems are recognized for higher productivity compared to CO2 laser systems, making them increasingly essential for industries seeking improved productivity. The flexibility of fiber lasers allows for compact designs of cutting heads, while their efficient cooling mechanisms enable continuous operation for longer durations. The absence of moving parts simplifies maintenance, particularly in electronic and medical industries with intricate products and micro-cutting applications.

However, fiber lasers are sensitive to contamination, particularly within the fiber optic delivery system. Dust, debris, or even slight damage to the fiber can affect the laser performance and beam quality. Thus, regular cleaning and maintenance are necessary to ensure optimal performance, which is expected to hamper the market growth.

On the contrary, the global shift toward electric vehicles is anticipated to offer remunerative opportunities for the expansion of the global fiber laser market during the forecast period. In addition, fiber lasers are used in various stages of electric vehicle production, including battery manufacturing, welding of components, and cutting of lightweight materials. The projected growth of the electric vehicle market will drive the demand for fiber lasers.

The global fiber laser market is segmented into type, application, and region. On the basis of type, the market is categorized into infrared fiber laser, ultraviolet fiber laser, ultrafast fiber laser, and visible fiber laser. By application, it is segregated high-power, marking, fine processing, and micro processing.

By type, the ultrafast fiber laser segment dominated the global market in 2022, and is anticipated to grow at a CAGR of 11.2% during forecast period. Ultrafast fiber lasers play a crucial role in semiconductor manufacturing processes. It is used in applications such as micromachining, wafer inspection, and defect analysis. Ultrafast lasers can accurately remove thin layers, create microstructures, and detect minute defects on semiconductor surfaces. Overall ultrafast fiber lasers are versatile tools with applications in scientific research, materials processing, biomedical imaging, optical communication, semiconductor manufacturing, metrology, and spectroscopy.

Their unique capabilities in delivering ultrashort pulses of light make them invaluable for studying ultrafast phenomena and performing precision operations in various fields. These factors together drive the overall market growth.

Region wise, it is studied across North America, Europe, Asia-Pacific, and LAMEA.

The Asia-Pacific fiber laser market size is projected to grow at the highest CAGR of 11.3% during the forecast period and account for 44% of fiber laser market share in 2022.

China has emerged as a global manufacturing powerhouse. The country has a strong presence in industries such as automotive, electronics, machinery, aerospace, and metal fabrication. These industries heavily rely on advanced laser technologies for various applications. Fiber lasers, with their high precision, fast processing speeds, and versatility, have become a preferred choice for manufacturers in China. The robust manufacturing sector in China has significantly contributed to the growth of the fiber laser market.

Fiber lasers offer high precision, fine control, and the ability to work with a wide range of materials, making them essential tools for achieving the desired quality. In

addition, surge in demand for high-quality products is driving the adoption of fiber lasers in India.

The material processing segment has experienced significant growth in the fiber laser market, with firms replacing CO2 lasers to enhance productivity and return on investment. The demand for fiber lasers in coding, marking, and miniaturization of ICs and wafers is fueling growth in materials processing applications.

The global fiber laser market is characterized by fragmentation, with major participants including ABB Ltd., Amonics Ltd., Coherent Inc., FANUC Corp., IPG Photonics Corp., Jenoptik AG, MKS Instruments Inc., NKT Photonics AS, OMRON Corp., and TRUMPF GmbH + Co. KG. The market forecast report provides a detailed analysis of these market leaders to help clients improve their market position.

Conclusion:

High Power Fiber Lasers have ushered in a new era of military technology, unlocking the potential for Laser Directed Energy Weapons to become a staple in defense systems. With breakthroughs in power scalability, beam quality, and efficient cooling, these lasers offer a versatile and precise means of countering evolving threats on the battlefield. As research and development continue, the deployment of laser weapons will likely become more widespread, reshaping the landscape of modern warfare. The era of laser-directed energy weapons has dawned, bringing with it the promise of enhanced security and strategic capabilities for military forces around the world.

References and Resources also include:

https://www.techbriefs.com/component/content/article/tb/features/articles/26467

https://www.alliedmarketresearch.com/fiber-laser-market