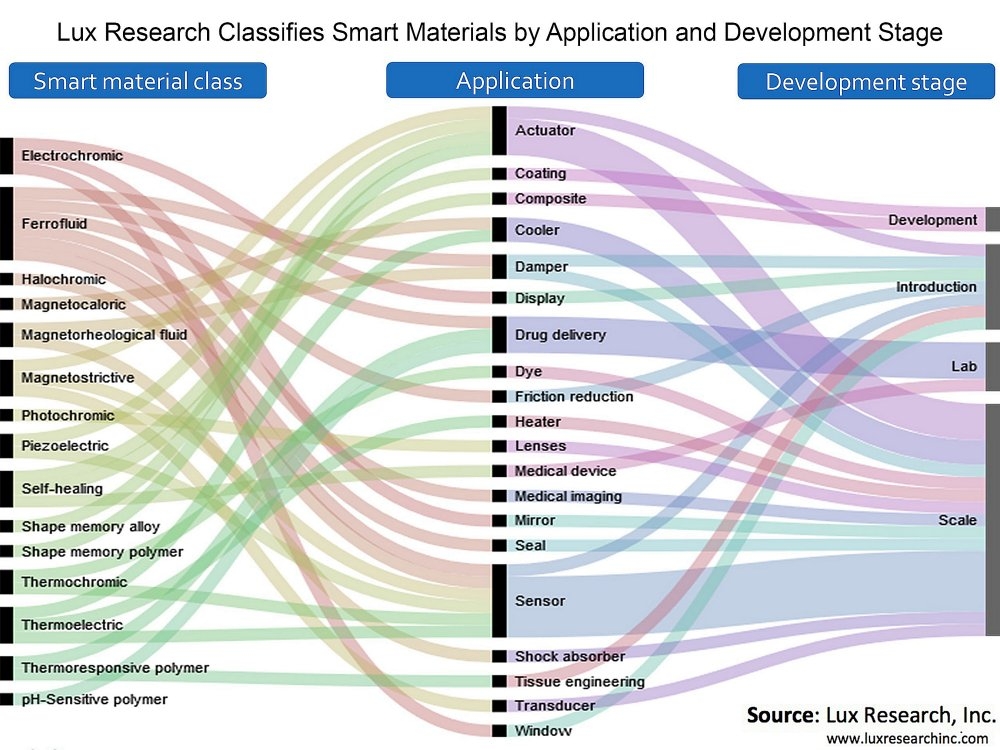

Smart materials or Active materials or Functional materials are designed materials that have diverse, dynamic features that enable them to adapt to the environment. They have one or more properties that can be significantly changed in a controlled fashion by external stimuli, the stimulus and response may be mechanical, electrical, magnetic, optical, thermal, or chemical.

Smart materials include self-healing materials, coatings with damage sensing, chemical sensing, friction changing, hydrophobicity changing capabilities, and also materials with several “smart” capabilities. They derive smart properties from structural patterning, often at the micro- or nanoscale, of already known material chemistries.

Smart materials are used to construct smart structures. A smart structure is a system containing multifunctional parts that can perform sensing, control, and actuation; it is a primitive analogue of a biological body. Smart structures are an integration of sensors, actuators, and a control system. Apart from the use of better functional materials as sensors and actuators, an important part of a “smarter” structure is to develop an optimized control algorithm that could guide the actuators to perform required functions after sensing changes.

New applications of shape memory materials are being demonstrated worldwide while new morphing structural concepts were tested in new ways. In 2019, Boeing and NASA’s Glenn Research Center in Ohio tested shape memory alloys, or SMAs, that could be incorporated into the composite materials that form the components of deployable structures on commercial airplanes. These SMA compositions would respond autonomously to ambient temperature changes. The new NASA-Boeing SMAs were incorporated into the hinge of a deployable vortex generator that was flight-tested on a Boeing 777-200 in November as part of the company’s ecoDemonstrator program. The vortex generator retracts at cruise to reduce drag.

In 2019, Texas A&M University researchers worked with University of British Columbia to develop SMA artificial muscle actuators mimicking the functionality of characterized bird muscles. Results were first presented publicly in May, showing that SMA components can act as actuators, brakes and structural components under cyclic stimuli, emulating avian muscle functions.

In July 2019 , the Harbin Institute of Technology in China revealed the existence of an experimental satellite that tested a prototype shape memory polymer composite for self-deploying solar arrays, or SMPCs. In a paper in the journal Smart Materials and Structures, the designers of the experiment, called Mission SMS-I, described the mission as the first SMPC demonstration in geostationary orbit. The authors said they have proved that their carbon-reinforced SMPC can deploy solar arrays by direct harvesting of solar energy without drawing system electrical power. To increase the stiffness of the solar array, new SMPC-based structures were studied this year toward the goal of a second round of flight testing, according to the authors.

Military and aerospace also have large demand for smart materials and devices including smart self-repair, smart clothing such as cloaking suits, winglets in aeroplanes that adapt automatically to changing flight conditions and adaptive hull structures for ships. The technology has been used in the head up displays of fighter pilot helmets to enable them to see the visual display even under conditions of rapid change in light intensity like going from bright sunlight into cloud or from cloud into bright sunlight. Smart materials could change shape to unfold a solar panel on a space satellite without need of a battery-powered mechanical device.

Smart Materials and Devices

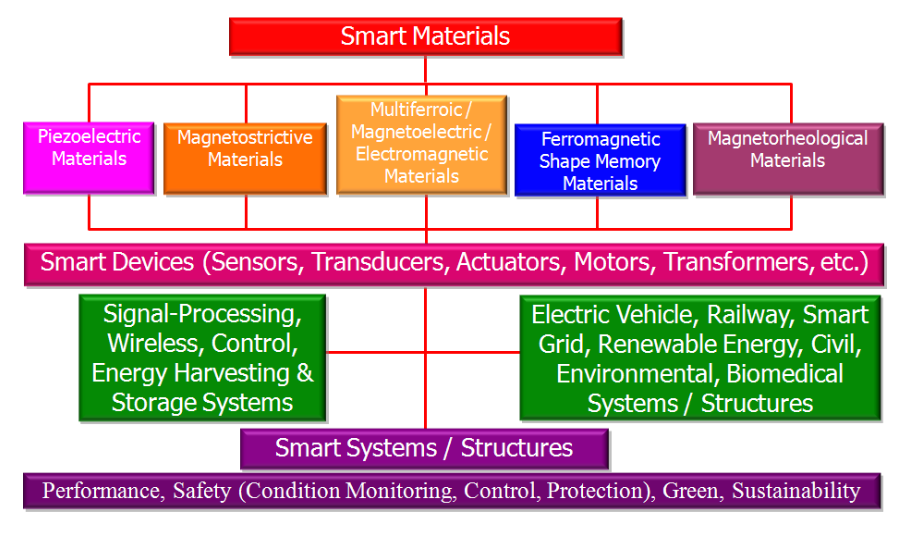

Mostly, “smart” materials are embedded in systems whose inherent properties can be favorably changed to meet performance needs. There are four of these aspects of which at least one is incorporated in a functional smart-material based device: smart materials can be sensors or actuators, they can be controlled or they can have biomimetic characteristics, according to Seung-Bok Choi of Department of Mechanical Engineering, Inha University, Incheon, South Korea.

Sensors are either bonded to the surface of a structural material or are embedded within a smart material to produce an electric signal proportional to the static or dynamic changes in the structural material.

Actuators are typically excited by an external stimulus, such as electricity, in order to change the stiffness and damping properties in a controlled manner. The control capability permits the dynamic behavior of the material to respond to an external stimulus according to a prescribed control algorithm associated to microprocessors.

The most promising materials with the above features are piezoelectric materials, magnetostrictive materials, magnetorheological (MR) fluids, electroactive polymers (EAPs), shape memory alloys, and electrostrictive materials.

Piezoelectric materials are materials that produce a voltage when stress is applied. Since this effect also applies in the reverse manner, a voltage across the sample will produce stress within the sample. Suitably designed structures made from these materials can therefore be made that bend, expand or contract when a voltage is applied. Piezoelectric materials are being used for contact sensors for alarm systems and in microphones and headphones.

Magnetorheological fluids are smart suspensions of soft magnetizable particles in non-magnetic liquid medium whose phase and rheological properties can be altered by an external magnetic field. They are commercially applied in a broad spectrum of areas due to their field-tunability. Shock absorbers, brakes, clutches, seismic vibration dampers, control valves, and precision polishing are just a few examples to illustrate their use.

Electroactive polymers are polymer-based composites in which electronic or ionic properties are embedded. EAPs exhibit a large displacement in response to external stimuli and hence can offer operational similarity to biological muscles. This is the reason why EAP materials have a really promising future in biologically inspired actuators.

They may drive various mechanisms for manipulation and mobility including microrobots, micro flying objects, tactile, and animatronic devices. Generally, the EAPs are divided into two major categories based on their activation mechanisms: electronic (driven by electric field or Coulomb forces) and ionic (involving mobility or diffusion of ions).

Military and Aerospace Applications

The demand for smart materials is being consistently driven by the growing need for such materials from the Military & Aerospace sector. Materials with enhanced functional properties such as shape memory, electrochromism and piezoelectricity, are gaining demand in the Automotive and Aerospace industries.

Piezoelectric materials are widely used in sensors and help in measuring fluid density, the force of impact, and fluid composition. These materials help in controlling the airflow across the wings of an aircraft and maintaining it during take-off and landing. Furthermore, these materials are also used to solve common problems with the aircraft, such as engine vibration, high cabin noise levels, ice formation on wings, flow separation due to turbulence, and control surfaces in cold climatic conditions. Also, piezoelectric materials find extensive applications in military and defense sector like smart sensors, smart nanorobotics, smart combat suits, and smart skins.

In aerospace, smart materials could find applications in ‘smart wings’, health and usage monitoring systems (HUMS), and active vibration control in helicopter blades.

Researchers at Clemson University, in South Carolina, are developing a layered film, or “skin,” that senses when it’s damaged. The thin layer of magnetostrictive film can change shape or dimension during the process of magnetization. The film is placed between two sheets of carbon fiber–reinforced polymer. The U.S. Army Research Lab in Adelphi, Md., gave the researchers a nearly $1 million grant to apply the material to military aircraft components. The goal is to help the Army reduce maintenance costs. The film essentially “feels” physical stress by sensing changes in the magnetic field. It sends data to a computer in real time. The skin also will be used on military vehicles to extend their lifetime, according to a Design News report

In 2014 GM began adopting a shape-memory wire in the Corvette C7 in place of a motorized actuator which reduced vehicle weight as well as mechanical complexity by replacing a complex assembly with a single substance.

Morphing Wing

A traditional aircraft is optimized for only one or two flight conditions, not for the entire flight envelope. In contrast, the wings of a bird can be reshaped to provide optimal performance at all flight conditions. Any change in an aircraft’s configuration, in particular the wings, affects the aerodynamic performance, and optimal configurations can be obtained for each flight condition. Morphing technologies offer aerodynamic benefits for an aircraft over a wide range of flight conditions. The advantages of a morphing aircraft are based on an assumption that the additional weight of the morphing components is acceptable.

The benefits of the use of morphing wings for UAVs make this technology important. UAVs with morphing wing technology; may increase its payload ratio, may achieve a shorter take-off distance, may land and stop in shorter distance, may take-off where runway clearance is limited, has more efficient altitude change at lower engine RPMs, can obtain higher cruise speeds, may decrease its stall speed, may lower its drag if necessary, thus; saving energy and time.

“Smart” materials and structures have the advantages of high energy density, ease of control, variable stiffness, and the ability to tolerate large amounts of strain. These characteristics offer researchers and designers new possibilities for designing morphing aircraft.

Shape memory alloys have attracted a great interest by many researchers as a promising morphing wing material because of its shape recovery upon application of voltage. Shape memory concept refers the property of a material or an alloy which regains its original shape when external load or electrical energy is applied. The design possibilities in the field of aerospace engineering are advanced by the unique thermal and mechanical properties of shape memory alloys now a day to improve the aerodynamic efficiency.

The types of morphing wings can be classified with regards to two purposes. The first one is to change the wing shape for the operating conditions or to improve the mobility. These morphing aircraft can perform multiple flight missions that are difficult to achieve using the fixed wing shape. The other one is to maximize the aerodynamic efficiency by substituting the section that causes aerodynamic losses.

Researchers at the Institut de Mécanique des Fluides and Laplace Laboratories, both in Toulouse, France, are creating an airplane wing [above] that can change its shape and vibrate along its edge, imitating the aerodynamics of birds, according to IEEE’s Engineering 360.

Shape-memory alloys are embedded in the wing’s surface to control the angle of the airplane’s wheels and allow for continuous wing movement. The European Commission provided 932,500 € ($1.1 million) to support the research. Airbus is the first airplane manufacturer to test the wing. It plans to complete test flights of the full-scale morphing wings starting in 2020. If successful, the technology will be integrated into the Airbus A340, the company says.

Morphing missiles being explored by the U.S. Air Force Research Laboratory would adjust their shapes in flight to provide aerodynamic benefits. Such concepts are enabled by novel actuator designs and morphing skins. Credit: U.S. Air Force Research Laboratory

Navy engineers design radar-absorbing structural armor reported in feb 2021

A research team at the Naval Surface Warfare Center’s Carderock Division in Maryland has developed armor that could help a small ship hide. Along with bullets and bombs, one of the armor’s structural layers is a ceramic composite with 3D conical-shaped inclusions that provide radar absorption.

“We began this project surveying the ballistic and ballistic material community for ‘rules of thumb’ to defeating the target projectile and velocity,” said Kruft, who worked with the Navy’s armor experts in Carderock’s Hull Response and Protection Branch to develop these rules of thumb. “The biggest challenge was staying true to these ballistic concepts while tailoring the composite to control electromagnetic energy propagation.”

The prototype was blasted with a gun three times and still showed significant wideband attenuation in radar bands of interest, according to the Navy. “We came up with an anti-reflective surface for our ceramic by trying to minimize the reflection of the side of the ceramic,” Good said. “Essentially, we measured the ceramic and a bunch of different geometrical layers. Then, working with our electromagnetic codes at Carderock, we were able to build up a design that achieved anti-reflective properties for that ceramic.”

The technology has both military and commercial applications, according to the Navy patent. “For example, an inventive embodiment of a ballistic armor structure may outperform existing ballistic armor structures. Structural and electromagnetic capabilities of an inventive material system may be incorporated by industry into commercial vehicles. The present invention can be embodied to provide a unitary composite structure that combines armor-protective, structural, and electromagnetically influential capabilities, the patent states. “Such combination of three functional capabilities is unique in the pertinent arts and can be beneficial in diverse applications. For instance, the combination of shaped ballistic ceramic inclusions with electromagnetic and structural properties may be advantageous for both large and small naval vessels.”

BAE is building explosion-proof military tanks that ‘bounce back’ into shape

In military operations worldwide, the threat of explosives disabling convoys of armoured vehicles looms large. Many vehicles already have pretty formidable armour to protect them from blasts but despite this protection, the suspension is often destroyed on impact, rendering the vehicle immobile and a sitting duck.

Aerospace and defence firm BAE Systems is using a bendable titanium alloy made from the same type of material used in flexible glasses, which enables the vehicle’s suspension to return to its normal form after impact. The design of the memory metal suspension was inspired by the hard shells and flexible legs of ironclad beetles. The insect’s exoskeletons are among the hardest of all arthropods.

Memory metal is presently used in bendable glasses and underwire bras and is a type of shape-memory alloy. These resiliant yet lightweight materials can be bent in any direction but will still return to their original shape. This is down to their superelasticity where the molecules inside the material pull back together after being moved and separated.

AFRL shape memory alloy (SMA) actuated release devices

The Air Force Research Laboratory (AFRL) has been actively developing low-shock, non-pyrotechnic spacecraft release devices to mitigate problems with traditional pyrotechnic devices. Specifically, pyrotechnic devices produce high shock, contamination, and have costly handling requirements due to their hazardous nature.

AFRL have provided funding for development and test of several shape memory alloy (SMA) actuated release devices. Through both ground testing and on-orbit performance, these devices have been shown to reduce shock by at least an order of magnitude, while remaining comparable in size and mass to pyrotechnic devices. The success of the low-shock devices is expected to pave the way for numerous applications, such as picosats, large spacecraft release, and fairing and stage separation.

Defence Research Establishment Ottawa, is investigating Smart structure technologies, based on a network of sensors and actuators, to increase the performance versatility and the structural stability of space structures. Large flexible space structures are required for phased arrays in space-based radar. These large space structures perform precision operations that require control of both rigid-body and elastic deformations.

EU-funded ADAM4EVE project for maritime

The EU-funded ADAM4EVE project, which ended in December 2015, has identified more than 20 innovative results that will pave the way for the development of new, adaptive, modern and efficient ship designs. Smart materials have been used to improve the ship’s performance as well as reduce the amount of energy needed for heating, cooling and passenger comfort.

Adaptive rudder-propeller can improve the manoeuvrability of a vessel. The rudder-propeller will allow the vessel to operate at design pitch when manoeuvring in port or locked at a 90-degree pitch in vertical plane in a seagoing condition.

Another development conceived by the project involved creating adaptive damping systems for thrusters in order to increase comfort levels on cruise vessels. Bow thrusters often produce high levels of noise and vibration but the easily-installed active control system reduces vibrations in areas where local modes are matched with the bow thruster excitation frequency

Results include adaptive windows for sailing yachts that allow the user to adapt the transparency of the yacht’s windows to increase or reduce sunlight. Other results, for example adaptive hull structures, have proven to be feasible, but will require further research, development and testing before being ready for market introduction.

DARPA

The DARPA supported several programs with a focus on smart materials and structures. The Smart Materials and Structures Demonstration projects aim to show the value of smart materials-based actuation systems in realistic applications. The Compact Hybrid Actuators Program (CHAP) efforts focus on the development of new types of useful electro-mechanical and chemo-mechanical actuators that exceed the specific power and power density of traditional electromagnetic and hydraulic-based actuation systems by a factor of ten for a range of applications.

Wind tunnel demonstrations of aeronautical adaptive structures

A number of new wind tunnel demonstrations of aeronautical adaptive structures applications were also performed in 2019. To quantify for the first time experimentally the acoustic benefit of an SMA slat cove filler in transport aircraft, researchers from Texas A&M University and NASA’s Langley Research Center in Virginia deployed a new aeroacoustic wind tunnel at Texas A&M in February and recorded a 2 decibel noise reduction at 20 meters/second on a 6.25% scale wing model.

An international team from Boeing, Deharde, the European Transonic Windtunnel and Langley demonstrated a new wind tunnel testing paradigm allowing airplane models to be actuated in a cryogenic wind tunnel, even given small model feature sizes. The test article consisted of a 4.5% scale Boeing-787 half-model with control surfaces powered by fully integrated SMA rotary actuators. In August, the model was tested at cryogenically simulated flight Reynolds number conditions. Another collaborative project initiated this year by the University of Maryland, University of Bristol and Intelligent Automation Inc. with NASA support demonstrated the feasibility of a camber morphing wing prototype. The prototype consisted of multimaterial 3D-printed morphing skins supported by a 3D-printed bioinspired flexure. The prototype’s 60-centimeter camber morphing section was actuated in a 24 m/s free jet wind tunnel with minimal flutter. Upscaling and flight tests are planned for future phases.

Regarding noncommercial applications of adaptive structures, in September 2019, the Aerospace Systems Directorate of the Air Force Research Laboratory first demonstrated a multiphysical “dry tunnel” that creates a simulated aerothermal test environment for morphing missiles. The approach gives researchers uninterrupted access to the structurally adaptive test article during simulated flight testing for full field strain and temperature tracking and allows testing of various missile articulation mechanisms across a range of speed and altitude conditions not achievable in traditional wind tunnels.

University of Central Florida researchers funded by the U.S. Navy’s Office of Naval Research in 2019 explored transient fluid-structure interactions during sea-based air vehicle morphing to find optimal configurations for modular high-stiffness structures. The researchers measured the unsteady forces on a twisting and bending compliant wing via water towing tank experiments, validating the concept and enabling new modeling approaches.

Future growth

Transparency Market Research (TMR), has published a new report titled “Smart Materials Market – Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2014 – 2020.” According to the report, the global smart materials market was valued at US$ 27.74 Bn in 2013 and is projected to reach US$ 63.28 Bn by 2020, expanding at a CAGR of 12.5% between 2014 and 2020.

Technavio’s market research analysts have estimated the global piezoelectric smart materials market to grow at an impressive CAGR of close to 13% over the forecast period. The increasing demand for piezoelectric smart materials from the military and aerospace sector is expected to drive the market for piezoelectric smart materials globally. The increasing demand for MEMS sensors, used in airbags and anti-lock braking systems, will translate into the demand for piezoelectric smart materials in the Americas. The market for piezoelectric smart materials will account for a market share of more than 47% until the end of 2020.

According to report published by Grand View Research, global smart coating market is expected to reach USD 11,676.0 million by 2024, owing to the rising demand from key end-user segments including military, aerospace, automotive, and healthcare. Growing application scope in end-use industries is attributed to superior properties including self-healing, self-cleaning and antimicrobial properties. Key participants in the industry include BASF SE, DuPont, 3M Company, PPG Industries, Dow Chemicals, and Dow Corning, among others.

References and Resources also include:

https://www.yahoo.com/tech/engineers-create-silk-based-materials-195053532.html

http://theinstitute.ieee.org/technology-topics/smart-technology/five-novel-uses-for-smart-materials

https://techlinkcenter.org/news/navy-engineers-design-radar-absorbing-structural-armor