The world’s oceans are vast and deep, and submarines have been a vital component of naval forces for decades. These underwater vessels can operate silently, dive to great depths, and strike from unexpected directions, making them an incredibly effective tool in modern warfare. However, the ability of submarines to remain undetected is crucial, and this requires the use of advanced materials and technologies to enhance their capabilities.

A nuclear submarine is a ship powered by atomic energy that travels primarily under-water, but also on the surface of the ocean. Previously, conventional submarines used diesel engines that required air for moving on the surface of the water, and battery-powered electric motors for moving beneath it. The limited lifetime of electric batteries meant that even the most advanced conventional submarine could only remained submerged for a few days at slow speed, and only a few hours at top speed. On the other hand, nuclear submarines can remain under-water for several months. This ability, combined with advanced weapons technology, makes nuclear submarines one of the most useful warships ever built.

Submarines provide unique warfighting capabilities including a stealthy platform with great range, mobility, endurance, payload potential, and survivability. In many hostile environments, the submarine may be the only survivable platform. Future submarines will offer a significant degree of flexibility and reconfigurability, both internally and through the use of off-board vehicles, sensors, and weapons; they also will accommodate rapidly emerging technology to improve current capabilities and to enable new roles and missions.

Advanced battle management systems that enable cooperative engagement with other naval forces will enhance the effectiveness of submarine participation in complex missions including antisubmarine warfare, strike operations, theater and national missile defense, and the deployment of ground forces for specialized warfare. The greater relative survivability (based on stealth, mobility, and endurance) of the submarine and the potential for expanding the range and depth of mission effectiveness suggest a greater role for submarines in the Navy of 2035

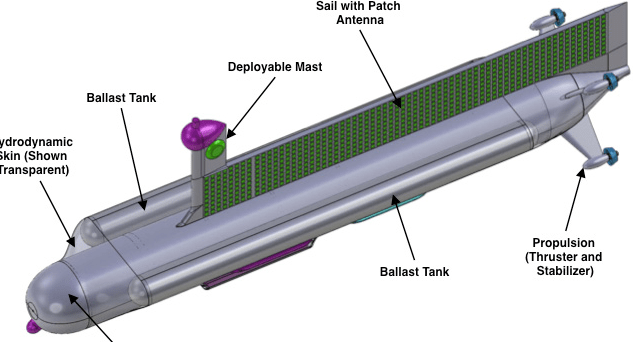

One of the technology focus areas is Submarine Architecture, including hull structure, shaping, and materials. It encompasses the use of innovative design, materials selection, and total systems integration to significantly improve submarine performance, payload capacity, and stealth while improving manufacturability and reducing costs. The goals of advances in architecture include greater speed for the same power input by reducing drag, greater stealth through the reduction of acoustic and nonacoustic signatures, and simplified fabrication using creative structural design and advanced materials.

An integrated approach is required because changes to individual architectural components affect hydrodynamic and operational performance. Various geometries and materials have been identified that could provide improvements in hydrodynamic performance and reduced target strength and, in the long term, provide space and surface area for embedded sensors. Improved sail shaping could reduce life-cycle cost by facilitating maintenance.

The main material used in manufacturing a nuclear submarine is steel. Steel is used to make the inner hull that contains the crew and all the inner workings of the submarine, and the outer hull. Between the two hulls are the ballast tanks, which take in water to make the submarine sink and eject water to make the submarine rise.

All small modern submarines and submersibles, as well as the oldest ones, have a single hull. However, for large submarines, the approaches have separated. All Soviet heavy submarines are built with a double hull structure, but American submarines usually are single-hulled. They still have light hull sections in bow and stern, which house main ballast tanks and provide hydrodynamically optimized shape, but the main, usually cylindrical, hull section has only a single plating layer.

A double hull submarine has two major components, the light hull and the pressure hull. The light hull (casing in British usage) of a submarine is the outer non-watertight hull which provides a hydrodynamically efficient shape. The pressure hull is the inner hull of a submarine that maintains structural integrity with the difference between outside and inside pressure at depth.

The double hull approach also saves space inside the pressure hull, as the ring stiffeners and longitudinals can be located between the hulls. These measures help minimise the size of the pressure hull, which is much heavier than the light hull. Also, in case the submarine is damaged, the light hull takes some of the damage and does not compromise the vessel’s integrity, as long as the pressure hull is intact.

Materials Requirements for Hull

The minimum thickness of the pressure hull required for a submarine can be reduced by using material with higher yield strength. A lesser thickness would be advantageous in reducing the weight, but comes at a cost of higher price

Depth is one of the most important and deciding structural design criteria. The pressure hull is the primary structural element of the submarine, and is designed to be able to withstand the external hydrostatic pressure. It is designed for a particular collapse depth, at which complete failure is expected within a very narrow range. The collapse depth is actually calculated by multiplying the maximum operable depth (MOD) or service depth with a factor of safety. The hydrostatic pressure at this depth is considered as the design pressure for all the pressure hull calculations.

A submarine is designed to withstand the loads generated by underwater detonations (for example, mine explosions, pressures generated by bursting of large underwater gas bubbles). Apart from the direct shock load imparted from the explosion, each shockwave from a single underwater explosion causes a wave of vibration to propagate along the pressure hull. Vibratory loads not only reduce the fatigue life, but can cause resonance resulting in major structural failure.

The pressure hull is generally constructed of thick high-strength steel with a complex structure and high strength reserve, and is separated with watertight bulkheads into several compartments. The constructions of a pressure hull requires a high degree of precision. This is true irrespective of its size. Even a one inch (25 mm) deviation from cross-sectional roundness results in over 30 percent decrease of hydrostatic load. Minor deviations are resisted by the stiffener rings, and the total pressure force of several million longitudinally-oriented tons must be distributed evenly over the hull by using a hull with circular cross section. This design is the most resistant to compressive stress and without it no material could resist water pressure at submarine depths. A submarine hull requires expensive transversal construction, with stiffener rings located more frequently than the longitudinals. No hull parts may contain defects, and all welded joints are checked several times with different methods.

For deeper understanding of Submarine hulls materials please visit: Submerged Resilience: Advanced Materials and Technologies Empowering Futuristic Submarine Hulls for Dominant Warfighting Capabilities

New Materials and technologies for Hulls

The hull of a submarine is its most important structural component, and it must be able to withstand the harsh conditions of the underwater environment. Traditional hull materials, such as steel, are heavy and can corrode easily. New materials, such as composite materials and ceramics, are lighter and more resistant to corrosion. They are also more expensive, but the benefits they offer can be significant.

In recent years, new materials and technologies have been developed that are specifically designed to enhance the performance of submarine hulls. These advancements have led to improvements in range, endurance, and stealth, making submarines an even more formidable force on the battlefield.

Advanced Composites

One of the most significant advancements in submarine hull technology is the use of advanced composites. These materials offer significant weight savings, making submarines lighter and more maneuverable. They are also stronger and more resistant to corrosion, which improves the longevity of the hull and reduces maintenance requirements. Advanced composites are also more durable, meaning they can withstand the stresses of deep dives and high-pressure environments.

Russia’s development of a new generation of nuclear-powered submarines is set to push the boundaries of submarine technology even further. These submarines, which will incorporate composite materials in their hulls and other parts, will allow for significant improvements in stealth and endurance.

Russia’s testing of composite propellers is also an important development. Propellers are one of the most critical components of a submarine, and the use of composite materials in their construction could have a significant impact on the submarine’s performance. By reducing vibration in the blades and increasing efficiency, the acoustic signature of the submarine can be improved, making it more difficult to detect.

The use of composite materials in submarines is not limited to Russia. The United States and other countries have also been exploring the use of composites in submarine construction. However, Russia’s adoption of these materials in its next-generation submarines is a significant step forward, and it is likely that other countries will follow suit in the coming years.

Other Materials

In addition to steel, various parts of a nuclear submarine are made from other metals, such as copper, aluminum, and brass. Other materials used to manufacture the thousands of components that make up a fully equipped nuclear submarine include glass and plastic. Electronic equipment includes semiconductors such as silicon and germanium. The nuclear reactor that powers the submarine depends on uranium or some other radioactive element as a source of energy.

Another significant development in submarine hull technology is the use of biomimicry. This technology involves mimicking the natural structure of marine animals to create a hull that is quieter and more stealthy. The use of biomimicry in submarine hulls has led to a significant reduction in underwater noise, making them more difficult to detect. This technology has also led to improvements in hydrodynamics, allowing submarines to move through the water more efficiently, which improves range and endurance.

Stealth technologies

Finally, there is research being conducted on new stealth technologies. Submarines are designed to be difficult to detect, but new technologies are being developed that can make them even more stealthy. These technologies include new hull designs, noise-canceling systems, and radar-absorbent materials.

China Develops New ‘Stealth Technology’ For Its Submarines That Can Dodge US Navy Sonars By Mimicking Water

Chinese scientists have developed new stealth technology for submarines that could potentially cancel out US Navy sonar, according to a report by the South China Morning Post in March 2023. The technology is based on a metamaterial that can effectively cloak a submarine from sonar detection.

The tile-like device can analyse enemy sonar frequency, and generate opposing sound waves to cause the sonar operator to mistake the submarine for water, the researchers said.

Low-frequency sounds produced by the tiles can reach an intensity of up to 147 decibels, which is louder than a rock concert and sufficient to “cancel out” some of the most powerful active sonars used by the US military or its allies, according to the team from the Beijing Institute of Technology.

Traditional “passive” sound-absorbing tiles, made of rubber or synthetic polymer, are usually less than 7 centimetres (2.8 inches) thick, and work best against sonar signals in a higher frequency range with wavelengths shorter than their thickness. But they may not be as effective against longer wavelengths, and therefore lower frequencies, as the two are inversely proportional.

“The frequency of modern active sonars is getting lower and lower, with wavelengths exceeding one metre,” lead researcher Wang Wenjie and his colleagues said in their paper.

A complete unit of the device is less than half the size and thickness of a brick, allowing engineers to stick them all over the hull of a submarine to tackle sonar beams from different directions.

The material can also be adapted for other military applications, including aircraft and ships. While it is not clear how far along the development of this technology is, it highlights the ongoing global competition to enhance submarine stealth capabilities.

Active Mounts.

Active mounts, which employ piezoelectric materials or other types of actuators to actively cancel mechanical vibration, can greatly attenuate major noise paths from the machinery to the hull. Such mounts can be incorporated into a system of shipwide active noise control techniques that will work together to maximize the effect of this technology at minimal cost.

Conclusion

In conclusion, the development of new materials and technologies for submarine hulls is critical to enhancing their warfighting capabilities. Advances in composite materials, biomimicry, coatings, and hydrophobic materials have all contributed to improved range, endurance, and stealth. As these technologies continue to evolve, submarines will become even more effective tools for naval forces around the world.

References and Resources also include:

https://www.marineinsight.com/naval-architecture/submarine-design-structure-of-a-submarine/

https://www.nap.edu/read/5839/chapter/6#87