The civil global aviation market has experienced considerable economic growth in recent years and will keep increasing. It is estimated that around 1300 new international airports will be required, and the commercial aircraft fleet will double by 2050, with a projected passenger throughput of 7.2 billion in 2035.

This growth is desirable from an economic standpoint, but aviation is predicated on fossil fuels, which increase greenhouse gas and air pollutant emission.

Presently, Aviation Industry generates 2-3 percent of the world’s human-generated carbon dioxide emissions and 12 percent of the CO2 emissions from all transportation sources. It is projected to rise to 11% if new technology is not advanced in the next two decades to cope with the projected annual growth of the aviation industry.

To reduce its impact on the environment and improve the sustainability of its operations, the commercial aviation industry has committed to achieve net-zero air transport emissions by 2050.

Although aircraft have seen many improvements in vehicle configurations and engine systems that have enhanced their flight efficiency, their continued dependency on hydrocarbon fuels means that commercial aviation will continue to contribute a significant amount of greenhouse gas emissions across the national and international transportation industry.

Achieving these goals requires disruptive innovation in the propulsion system of aircraft. The need to reduce gas emissions, optimize aircraft performance, decrease operating and maintenance costs, is pushing aircraft industry to progress towards more electric aircraft (MEA), and ultimately an All Electric Aircraft. Electric propulsion can be powered by rechargeable batteries, fuel cells, or solar energy.

The Clean Sky initiative launched in public-private partnership between the European Commission and the European aeronautics industry had announced plans to improve the MEA performance to reach 20-30% lesser fuel consumption and related CO2 emissions. Airbus and Boeing are two aircraft dealers operating MEA, and Boeing’s B787 is the only aircraft in the MEA segment which has successfully balanced fuel consumption and weight to deliver power equal to that of a fully ATF powered aircraft engine

Rolls-Royce in Jan 2019 revealed plans to build a 300-mile-per-hour, 500-horsepower, all-electric aircraft capable of flying from London to Paris on a single charge.

Researchers at NASA’s Glenn Research Center are actively researching the next generation of efficient aircraft. One of their current objectives is to help shift the industry from solely using gas turbines to start implementing hybrid or turboelectric propulsion. The benefits of this are reduced energy consumption, emissions, and noise.

Boeing backed Zunum Aero’s 12-seat plane will be powered by battery packs with a small fuel reserve for a back-up engine. According to the company, the first model will fly about 700 miles, far enough to ferry travelers from Boston to Washington or Silicon Valley to Los Angeles. Short-haul flights produce over 40 per cent of aviation emissions. Zunum said in a sttement, “With our aircraft, we believe these will be largely eliminated within twenty years.

Our aircraft are ”hybrid-to-electrics” that sip fuel only when they have to, will use even less over time as batteries upgrade, and will one day go completely without. They add, Zunum’s plans reveal a rush to develop small electric aircraft based on rapidly evolving battery technology and artificial intelligence systems that avoid obstacles on a road or in the sky.

Military is also interested in the gains like obtaining the weight savings benefits of a full more electric architecture implementation. Joint Strike Fighter (JSF), C-141 transport aircraft, and UAV’s like Condor, Global Hawk and Dark Star are some examples where the MEA concept has been introduced. With MEA technology, the weight in an aircraft can be shifted from hydraulic systems and plumbing to passengers, fuel or mission payloads. MEA technology could dramatically reduce per passenger costs and ticket prices for commercial aircraft, while giving military planes more maneuverability and survivability due to less vulnerability to enemy fire, says Honeywell.

Whilst full electric flight in the civil aviation sector is still a long way in the future, electrically assisted engines, a hybrid technology step, will soon be possible and the consequences of this technology change in terms of aircraft engine design and aircraft efficiency improvements are important to the industry.

The report “More Electric Aircraft Market – Global Forecast to 2021”, estimates the more electric aircraft market to grow from USD 7.68 Billion in 2016 to USD 10.94 Billion by 2021, at a CAGR of 7.33% from 2016 to 2021.

More Electric and All Electric Aircrafts

More Electric Aircraft (MEA) are future-generation aircraft that are equipped with more electrical systems to minimize non-propulsive power systems, such as mechanical, hydraulic, and pneumatic systems including flight control actuation, environmental control system, and utility function. In the “No-Bleed” architecture, the pneumatic aircraft systems, namely engine starting, wing de-icing, landing gear deployment system, secondary flight control actuators, cabin pressurization, environmental control, and braking systems will be replaced by electrically powered machines. This has resulted in a reduction in the weight of the aircraft, usage of less fuel, and reduction in emissions, leading to a low cost of ownership and increased reliability.

For more information about the technology and applications of Electric Aircraft please visit: Electric Skies: How Electric Airplanes are Revolutionizing the Future of Air Travel

The final destination will be all-electric propulsion, where conventional combustion engines will be completely superseded by a purely electric power source. A growing number of projects exploring the many possibilities are being conducted around the world, led by established industry players and startups alike.

Hybrid or all-electric propulsion offers significant benefits:

1. Enhanced performance

Huge technological progress has been made with latest-generation combustion engines, and further advances are possible by optimizing

architectures, materials and coatings to boost performance. Hybrid layouts are another way to reduce weight, fuel burn and environmental

impact, especially by avoiding the need to design the main combustion engine to meet maximum power requirements, for example at

takeoff.

2. More reliable operation

More-electric architectures are more robust and require less maintenance. Smart electronic management makes them potentially more

compatible with new digital technologies, allowing data to be collected and analyzed for greater automation, optimized flight and better

failure prediction and management.

3. New markets

By increasing the number of electric motors, certain architectures such as multi-rotor VTOLs are inherently much safer and could open up a

host of new uses in urban and suburban areas, as well as bringing this kind of flying to many more people, thanks to manually-assisted or

fully-automated operation.

Electric motors offer other advantages too compared to combustion engines, they don’t need air to produce power, so they can maintain their full rated punch even at high altitudes, where the air is thin. The use of electric power in airframe systems saves fuel and helps in cost reduction. Electric motors can be made quite light and small and still develop considerable power with high reliability—they scale well. Air-breathing engines, both reciprocating and turbine, have many more moving parts, are more complex. The more electric aircraft architecture also helps in reducing maintenance costs as it requires fewer moving or non-moving parts, as compared to the conventional aircraft systems.

German said the trend in the military is for “more electric,” writes Stew Magnuson in NDIA. That is, jets need more power to run its suites of energy-hungry electronics, radars, and so on. It wants less fuel being diverted to these systems. “Another flight profile might be an unmanned aerial surveillance aircraft that uses the gas engine for the flight to a targeted area, then switches over to the much quieter battery in order to be more stealthy, or extend its range,” writes Richard “Pat” Anderson, professor of aerospace engineering and director of the Eagle Flight Research Center at Embry-Riddle Aeronautical University’s Daytona Beach, Florida, campus.

Challenges

More Electric Aircraft (MEA) applications demand high reliability, high availability, and high power density while aiming to reduce weight, complexity, fuel consumption, operational costs, and environmental impact. New electric driven systems can meet these requirements and also provide significant technical and economic improvements over conventional mechanical, hydraulic, or pneumatic systems. However, the MEA puts some challenges on the aircraft electrical system, both in the amount of the required power and the processing and management of this power.

Using electrical power to actually propel planes, however, is a more complicated challenge. In a conventional jet airplane, the engine sucks air in through its front, a compressor squeezes it, and fuel is sprayed in and lit, creating burning gases and forward thrust. Electric plane power is much simpler — batteries power an electric motor that spins a propeller. It’s more efficient, but involves far less thrust, which is why electric planes tend to be slow.

“For an electric airplane, the top three priorities are weight, weight and weight,” said Cory Combs, co-founder and chief technology officer of Los Angeles-based Ampaire, Inc. “It has to spend a lot of its energy just keeping itself in the air.” The fundamental challenge, he explained, is that an electric plane has to carry enough battery power to allow it to take off carrying a nominal payload of passengers or cargo, fly at a reasonable speed, then travel a sufficient distance, notionally 100 miles, to make it commercially viable. If its battery packs become too large or too heavy, the aircraft will have a limited ability to carry passengers and cargo. This energy requirement is exacerbated, Combs added, by the Federal Aviation Administration (FAA)’s requirement that all aircraft must carry at least 45 minutes of reserve fuel, enough to divert to another airport or go around for another landing attempt.

The most significant limiting factor at this point is not the weight of the engines, or the design of the aircraft, but rather it is the batteries. Batteries at this point cannot provide the power-to-weight ratio needed for electric aviation to be feasible. Currently, jet fuel yields about 70 to 80 times more energy than an equivalent mass of battery. In addition, Batteries have a higher maintenance costs than gas turbines, and on top of that require replacement after only 1,500 charge cycles.

“Lithium (Li) ion batteries are the current state-of-the-art stored energy technology for aviation,” said Dr. Ajay Misra, deputy director, Research and Engineering Directorate, NASA’s Glenn Research Center, “the same type of technology used in cells phones and electric cars.” For aviation, Misra added, the relevant measure of battery suitability is called pack specific energy, also referred to as pack gravimetric energy density. A pack contains thousands of battery cells. The units of pack specific energy are watt-hours per kilogram (Wh/kg). According to Misra, the pack specific energy of the most commonly used Li-ion batteries today is about 150 to 170 Wh/kg. By contrast, the specific energy of jet fuel is nearly 12,000 Wh/kg, or about 70 to 80 times more energy dense than Li-ion batteries.

One of the ways the technology can be applied for larger aircraft is distributed power systems, German said. For example, the larger a gas-turbine engine is the more efficiency can be squeezed out of it. That’s why there tends to be only a few massive engines hanging off aircraft such as the C-17. Researchers have known for many years that putting many smaller propellers or engine fans, distributed at key areas would be even more efficient. Every aircraft has a boundary layer, an area of dead air above the wing that builds up and creates drag as the plane flies. By placing several smaller fans along the aircraft, the boundary layer is “ingested” and almost disappears, making the aircraft faster or more energy efficient, German explained.

Another challenge that exists is creating a practical cooling system that can be used. Thermal management for these systems will require a system that can reject anywhere from 50 to 800 kW of heat in flight. A cooling system is required for the integrated power module used for high-power electronics. Materials will need to be developed for improved thermal performance, and a lightweight system developed for the power electronics cooling. Superconductivity and supercooled electronics will be required to reduce the electrical resistance of the aircraft.

Electric Aircraft demonstrations

The vision of an electrically powered commercial airplane turned from a dream to a possibility when Solar Impulse 2, a solar-powered plane that completed an around-the-world journey in 2016. Earlier in July 2015, the E-Fan, an Airbus design with batteries, crossed the English Channel, however Airbus’ two-seat electric plane could only go a maximum speed of about 136 miles per hour. Contrast that to a Boeing 787, which flies at 585 mph, and carries more than 242 passengers.

The plane, called Solar Impulse 2, had more than 17,000 solar cells that powered four electric motors. “But solar power, while an interesting technical challenge, is not a particularly realistic option for mass transit of passengers. As can be seen from the Solar Impulse aircraft, the power output from the Solar Panels on a very wide wingspan is able to transport only the aircraft and the pilot for any significant distance,” writes Dr Peter Wilson.

According to Roei Ganzarski, CEO of magniX, a Redmond, Washington producer of electric motors, however, electric aviation is facing a chicken/egg situation. “You’re not going to get batteries for aviation unless there’s an electric airplane that needs them,” he explained. “And no one is going to design and build an electric plane unless there’s an electric propulsion system that can power the plane.” That’s why Ganzarski believes that electric propulsion will drive the so-called third revolution in aviation, just as the automotive-derived piston engine used by the Wright Flyer launched the first revolution, and the advent of the jet engine ushered in the second.To support this idea, magniX is working with Vancouver, B.C.- based Harbour Air, a regional airline, to retrofit several types of seaplanes with electric propulsion systems. In Dec. 2019, the two companies conducted first flight of the world’s first fully-electric commercial aircraft, a five-passenger de Havilland Canada DHC-2 Beaver propelled by magniX’s Magni500 560kW system.

The age of electric flight is finally arriving. Harbour Air, North America’s largest seaplane airline and magniX, the company powering the electric aviation revolution, announced the successful flight of the world’s first all-electric commercial aircraft in Dec 2019. The successful flight of the ePlane, a six-passenger DHC-2 de Havilland Beaver magnified by a 750-horsepower (560 kW) magni500 propulsion system, took place on the Fraser River at Harbour Air Seaplanes terminal in Richmond (YVR South). In July 2019, Paris Airshow saw the launch of the world’s first commercial all-electric passenger aircraft – albeit in prototype form. Israeli firm Eviation says the craft – called Alice – will carry nine passengers for up to 650 miles (1,040km) at 10,000ft (3,000m) at 276mph (440km/h). It is expected to enter service in 2022.

In coming months, magniX will be seeking FAA certification of its Magni500 motor while Harbour Air hopes to obtain certification for the DHC-2 Beaver. Eventually, the air charter company hopes to electrify its entire fleet of approximately 40 seaplanes. Current FAA regulations, adopted in 2017, allow certification of electric airplanes weighing 19,000 pounds or less, with 19 or fewer passenger seats. As Ganzarski sees it, retrofitting existing, previously-certified aircraft with new electric propulsion systems is a faster, less expensive way to reduce air pollution through electric aviation than building electric airplanes from scratch. “The FAA already knows the de Havilland Beaver,” he said. “There’s nothing ‘new’ about this aircraft except now it will be electrically powered.” The downside of electrifying older seaplanes, Ganzarski admits, is that they won’t have the range of the original aircraft, which were designed with large, heavy engines on the front. Traditional seaplanes can also carry high-energy-density fuel in their wings and don’t need to make room for lots of heavy batteries.

For the foreseeable future, explains NASA’s Misra, Li-ion batteries will remain the go-to stored energy technology for electric airplanes. “With incremental increases in the chemistry of the Li-ion battery, its pack specific energy could rise another 20 to 30 percent, reaching perhaps 200-220 Wh/kg,” he said. “More advanced battery chemistries, such as those using silicon or lithium metal anodes (vs the graphite anode used by most Li-ion batteries today) may be able to reach 300, even 400 Wh/kg, if we are lucky.” These specific energy levels, he believes, could enable introduction of all-electric regional jets capable of carrying 10 to 20 passengers, or slightly larger (50 to 70 passenger) jets powered by hybrid-electric propulsion systems.

“Within 10 years, we will likely see hybrid-electric regional jets capable of flying 500 miles,” projected Misra. “Larger, all-electric passenger jets like the 737, however, are not likely before 2040 as significant advances in battery technology will be required.”

Brian German, associate professor at the Daniel Guggenheim School of Aerospace Engineering at Georgia Tech, said there are no distinct lines in the sand yet for aircraft categories, but generally researchers are looking at all-electric, or battery only, systems for smaller aircraft and various hybrid or turbo-electric systems to power the larger ones.

Engineers look at this one of two ways. It’s either making the engine fans more efficient, or creating less drag on the wing. Both effects are at play, German said. This is the principle behind DARPA’s LightningStrike vertical takeoff and landing X-plane that it is developing with Aurora Flight Sciences. An artist’s rendering of the plane shows 26 hybrid-electric propulsion fans distributed on the aircraft. The program has flown a 325-pound scale model and expects to build a full-scale version within the next two years, the company said in a statement. Operating from austere landing zones is the requirement the program is seeking to fill, it said.

Rolls-Royce Aims For Electric Aircraft Speed Record

In Sep 2020, Rolls-Royce announced that it has completed testing of the ground-breaking technology that will power the world’s fastest all-electric plane. All the technology has been tested on a full-scale replica of the plane’s core, called an ‘ionBird’, including a 500hp electric powertrain powerful enough to set world speed records and a battery with enough energy to supply 250 homes. Rolls-Royce in Jan 2019, revealed plans to build a 300-mile-per-hour, 500-horsepower, single-seater all-electric aircraft capable of flying from London to Paris on a single charge.

Over 6,000 cells are packaged in the battery for maximum safety, minimum weight and full thermal protection. Since January, our engineering and test pilots have spent many hours optimising the system and developing operating procedures for electric flight.

Generating GBs of data every hour of operation which the team have analysed to improve performance wherever possible.

The Accel relies on the most energy-dense battery pack every assembled for an aircraft—6,000 cells packaged together for lightness and thermal protection, combined with an advanced cooling system built to withstand extreme temperatures and high-current demands in flight. The nose-mounted propeller is powered by three high-density electric motors. The propeller spins at a much lower rpm than an aircraft with conventional propulsion, yielding a smoother and quieter ride.

The all-electric power train runs at 750 volts while delivering 90% energy efficiency and zero emissions. Onboard sensors monitor 20,000 different points on the powertrain, measuring diverse metrics including battery temperature and battery voltage. When the Accel takes to the air in 2020, Rolls-Royce plans to set the speed record for all-electric flight (the current record is 210 mph set by Siemens in 2017).

“This plane will be powered by a state-of-the-art electrical system and the most powerful battery every built for flight,” Accel project manager Matheu Parr said in a statement. “In the year ahead, we’re going to demonstrate its abilities in demanding test environments before going for the gold in 2020 from a landing strip on the Welsh coastline.”

Accel is just a small part of Rolls-Royce’s vision for a more-electric aviation future that could soon start showing up on jet engines. Last year the company shared its vision of how electric aircraft engines hold the promise of reduced noise, emissions, and operating costs via four likely development pathways: more electric, full electric, partial hybrid, and full hybrid.

Boeing’s experimental autonomous aircraft completes its first test flight

Boeing has completed a series of fuel cell demonstrator flight tests, and recently wrapped up a NASA study that identified hybrid electric propulsion technology as having good potential to meet future environmental goals for air vehicles in the 2030 to 2050 timeline.

Aurora Flight Sciences, a subsidiary of aerospace giant Boeing, said in Jan 2019 that it recently conducted the first test flight of its all-electric autonomous passenger air vehicle. The unpiloted vehicle took off vertically, hovered for a few seconds, and then landed at the company’s test site in Manassas, Virginia. Boeing said that future flights will test forward, wing-borne flight, as well as the transition phase between vertical and forward-flight modes.

Powered by an electric propulsion system, Boeing says the prototype is designed for fully autonomous flight from takeoff to landing, with a range of up to 50 miles (80.47 kilometers). Measuring 30 feet (9.14 meters) long and 28 feet (8.53 meters) wide, its airframe integrates the propulsion and wing systems to achieve efficient hover and forward flight (also known as vertical takeoff and landing, or VTOL). It’s a significant step toward a future in which autonomous, electric “flying taxis” zip from skyscraper to skyscraper, bearing passengers and cargo in service of an entirely new form of urban mobility.

A small experimental airplane recently took to the skies near Sywell Aerodrome near Northampton, United Kingdom, for an important test flight. Unlike traditional engines, the hybrid electric propulsion system used in this flight test consisted of an internal combustion engine and an electric motor/generator. Researchers said the aircraft can fly using the engine or the electric motor, or both in combination. The engine can also power the generator that can charge the battery, allowing the airplane to use the electric motor during a later phase of the flight.

The demonstrator aircraft uses up to 30% less fuel than a comparable plane with a petrol-only engine. The aircraft is also able to recharge its batteries in flight, the first time this has been achieved. During take-off and climb, when maximum power is required, the engine and motor work together to power the plane, but once cruising height is reached, the electric motor can be switched into generator mode to recharge the batteries or used in motor assist mode to minimise fuel consumption. The team also developed an advanced battery management and state-of-health monitoring system.

“Until recently, batteries have been too heavy and didn’t have enough energy capacity. But with the advent of improved lithium-polymer batteries, similar to what you’d find in a laptop computer, hybrid aircraft – albeit at a small scale – are now starting to become viable,” said Dr Paul Robertson of Cambridge’s Department of Engineering, who led the project.

NASA’s 18-Engine Electric Propulsion-Powered Experimental Aircraft Underway

NASA is researching ideas that could lead to developing an electric propulsion-powered aircraft that would be quieter, more efficient and environmentally friendly than today’s commuter aircraft. Currently there is a project underway known as the NASA Electric Aircraft Testbed. This project is looking at the current technology obstacles of electric flight. With this testbed, increased efficiency and reduced weight are the goals. The testbed can be adapted to power larger and larger engines as technology is improved.

The proposed piloted experimental airplane is called Sceptor, short for the Scalable Convergent Electric Propulsion Technology and Operations Research. The concept involves removing the wing from an Italian-built Tecnam P2006T aircraft and replacing it with an experimental wing integrated with electric motors.

An advantage of modifying an existing aircraft is engineers will be able to compare the performance of the proposed experimental airplane with the original configuration, said Sean Clarke, Sceptor co-principal investigator at NASA’s Armstrong Flight Research Center in California. The Tecnam, currently under construction, is expected to be at Armstrong in about a year for integration of the wing with the fuselage. Armstrong flew a different Tecnam P2006T in September to gather performance data on the original configuration.

NASA researchers ultimately envision a nine-passenger aircraft with a 500-kilowatt power system in 2019. To put that in perspective, 500 kilowatts (nearly 700 horsepower) is about five times as powerful as an average modern passenger car engine.

However, to reach that goal NASA researchers intend to fly the Aeronautics Research Mission Directorate-funded Sceptor in about two years. Progress in three areas is happening now to enable that timeline, Clarke said.

One step in this process involves testing an experimental wing on a truck (yes, on a truck). This is called the Hybrid Electric Integrated Systems Testbed (HEIST). HEIST’s first experiment was called the Leading Edge Asynchronous Propeller Technology, or Leaptech. The experiment began in May at Armstrong and consisted of 18 electric motors integrated into the carbon composite wing with lithium iron phosphate batteries.The wing is made of carbon composite, while the electric engines are powered by lithium iron phosphate batteries.

Tests so far show the distribution of power among the 18 motors creates more than double the lift at lower speeds than traditional systems, he said. Leaptech is a collaboration of Armstrong and NASA Langley Research Center in Hampton, Virginia, and California companies Empirical Systems Aerospace of Pismo Beach and Joby Aviation of Santa Cruz. Key potential benefits of Leading Edge Asynchronous Propeller Technology (LEAPTech) include decreased reliance on fossil fuels, improved aircraft performance and ride quality, and aircraft noise reduction.

For example, researchers are integrating Sceptor aircraft systems with an Armstrong flight simulator for pilots to evaluate handling qualities. Researchers also will be able to study balancing the power demands of the motors with batteries and then a turbine, Clarke explained. Researchers are interested if a hybrid of distributed electric motors and gas-powered turbines could provide power to extend the aircraft’s range and enable the envisioned 9-place concept aircraft, Clarke explained.

Sceptor could be a solution to greater fuel efficiency, improved performance and ride quality and aircraft noise reduction. NASA will be key in developing those technologies for the future that will be with people when they fly.

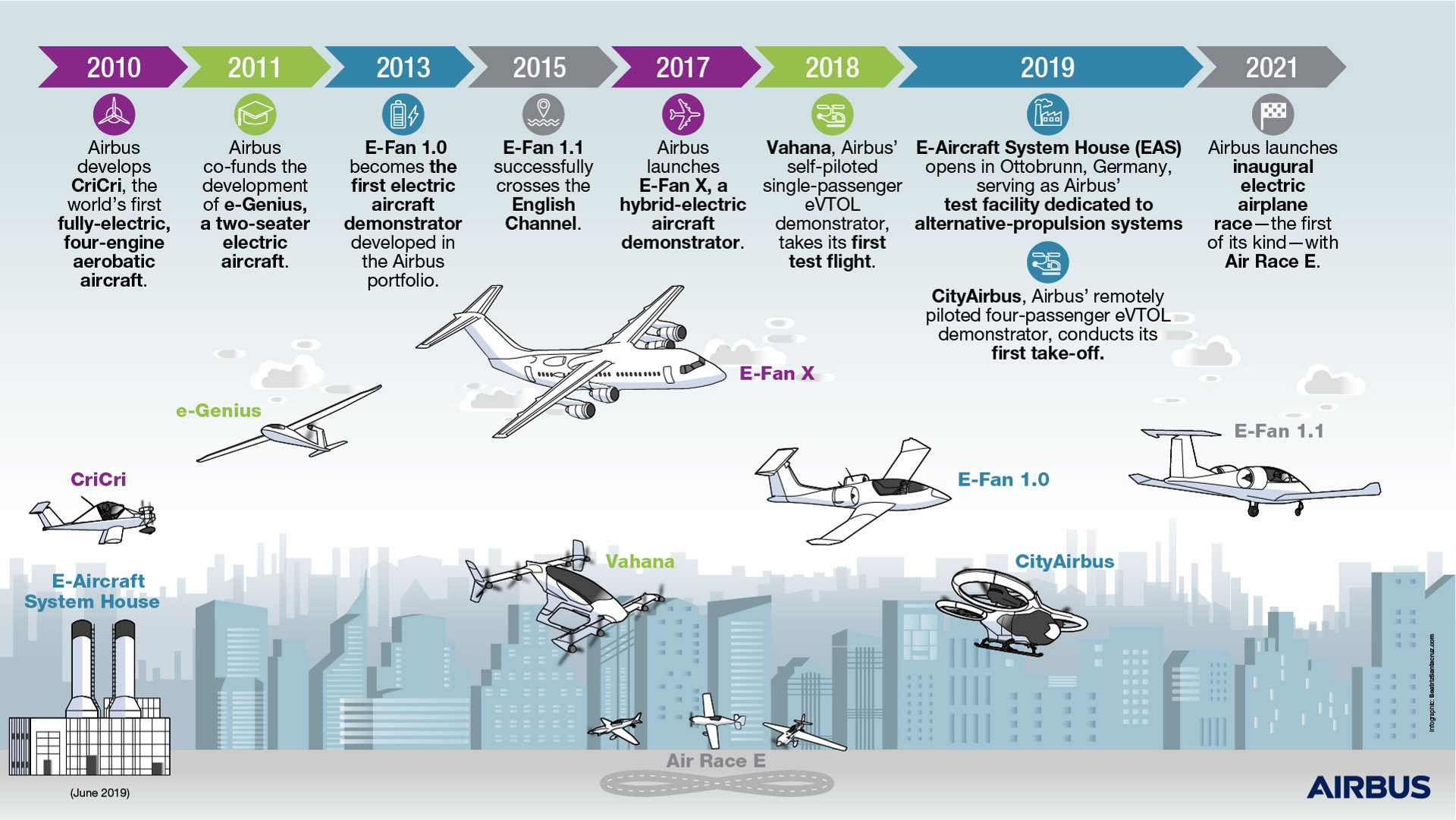

Airbus Group Innovations has flown its E-fan with hybrid propulsion

Airbus Group Innovations has flown its E-fan proof-of-concept electric aircraft with hybrid propulsion, adding an internal-combustion engine as a range extender. The 600-kg (1,320-lb.) aircraft has an endurance on batteries only of 30 min. This is increased to 2 hr. 15 min (plus recharging the batteries to 80%) using the range extender, a two-cylinder, two-stroke piston engine with electronic fuel injection providing 50 kw (68 hp) of power on aviation gasoline. The Solo 2625 02i engine, certified for use in ultralights, weighs 24 kg dry.

The combustion engine sits behind the cockpit, and is only used to charge the plane’s lithium-ion batteries which are embedded in the wings. The combustion engine doesn’t provide any of the plane’s thrust. The two ducted fan engines that do give the plane its thrust are mounted on each side of the fuselage. The plane takes off and lands on electric power only — to make it as quiet as possible. The combustion engine will charge the batteries only during the cruise portion of each flight.

In its previous all-electric configuration, as the E-Fan 1.1, the aircraft crossed the English Channel on electric propulsion in July 2015, a flight lasting 37 min. Airbus is confident that it can also reduce the carbon emissions for all new aircraft by 75 percent.

This small two-seater experimental aircraft called ‘E-Fan’ measures 19 feet from nose to tail, has all-composite construction and manufactured by Toulouse-based Airbus. It has pair of electric engines generating a combined power of 60 KiloWatts powered by 120 lithium-ion polymer batteries, enough to sustain one hour of flight. Airbus is working with general aviation manufacturer Daher and electric motor supplier Siemens to put the two-seat, all-electric E-Fan 2.0 into production as a training aircraft.

Israeli Electric aircraft

Eviation Alice is an Israeli electric aircraft that is under development by Eviation Aircraft. This plane features three propellers, two on the wingtips and one in the rear of the plane body. The plane features an electric propulsion system and is developed from 95 percent composite materials.

The aircraft, named Alice, doesn’t just swap jet fuel for batteries but is a whole new design concept that improves the way the propulsion system is integrated into the airframe.The company was started in 2015 and is currently underway to manufacture the first prototype of its all electric business and commuter aircraft. Carrying nine passengers with a range of 1,000km, Alice is expected to enter service in 2022.

DARPA’s Lightning Strike vertical takeoff and landing X-plane

The US Defense Advanced Research Projects Agency’s (DARPA’s) LightningStrike vertical take-off and landing (VTOL) X-Plane programme has completed an initial flight demonstration phase with a scale model. DARPA said the subscale X-Plane model demonstrated auto takeoff, sustained hover, directional and translational control, waypoint navigation and auto landing functions during flight tests that began in March 2016. That test run is now over and officials will next focus on a full-scale system demonstration.

The SVD aircraft is a 325 pound, Lithium battery powered scale model of the 12,000 pound, 61 foot wingspan XV-24A. It will remain in flight status to supplement the full-scale XV-24A flight test program, currently scheduled to begin in late 2018.

Industry, university collaborate on hybrid-electric aircraft

International aircraft manufacturing leaders have teamed with aerospace, aviation and research institute Embry-Riddle Aeronautical University to design a hybrid-electric turboprop aircraft. The goal is to produce a commercially viable, nine-passenger hybrid turboprop by 2025, and a large hybrid-electric jet by 2035. “The confluence of modern controls, batteries and the overhaul of the regulatory landscape make this the right time to design the air vehicles of the future,” said EFRC Director and Professor of Aerospace Engineering Dr. Richard “Pat” Anderson, who is the founder and lead for the consortium.

The three-phase, multi-year project aims to produce a prototype 600 SHP turboprop engine. Utilizing battery packs as the power source, the design will address weight concerns and technology needs. Having completed Phase I — the conceptual design of clean-sheet hybrid turboprop airframes and propulsion systems — the consortium is now in Phase II, which includes designing the motor, battery packs and battery management systems. Phase III is completing a design of the prototype engine and associate systems, increasing ground test facility capabilities, manufacturing and testing the prototype motor.

MEA and AEE market

The global More Electric Aircraft Market was valued at USD 1.8 billion in 2019, estimated to be USD 3.4 billion in 2022 and is projected to reach USD 8.6 billion by 2030, at a CAGR of 12.2% from 2022 to 2030. The aircraft electrification technology is installed to enable the evolution of traditional aircraft operating on conventional fossil fuels into electrically operated aircraft.

Some of the major factors driving the growth of the global aircraft electrification market are an increase in global government concerns about environmental pollution, stringent rules regarding carbon emissions through airplanes by the aircraft industry to reduce aircraft noise, and low operational costs.

Growing demand for high-performance fuel-efficient aircraft and an increase in demand for less polluting aircraft has led to rapid rise in research activities for the development of commercially viable electric aircraft. The important driver for these research activities and the introduction of new electric aircraft in the market are the various advantages of aircraft electrification over other traditional technologies such as noise reduction, reduced carbon emissions, lower vibrations, and simpler design for manufacture and maintenance.

Reduced maintenance costs and improved reliability because the MEA architecture uses fewer parts than previous systems is expected to increase the growth of the electric aircraft market. Recent technological advancements in the field of power electronics, fault-tolerant architecture, electro-hydrostatic actuators, flight control systems, high-density electric motors, and power generation and conversion systems have fuelled the adoption of MEA. More Electric Aircraft (MEA) technology allows for gradual improvements in aircraft efficiency through the use of electric and hybrid-electric power sources.

Electric aircraft’s restricted range and capacity, on the other hand, are projected to hinder market expansion. On the other hand, advancements in superior power electronics components and Lithium-ion battery technology are expected to open up the attractive potential for the electrified aircraft propulsion market.

In traditional architecture, the engines provide the majority of secondary aircraft systems power needs in pneumatic form. However, in the MEA architecture, the engines (no-bleed) provide the majority of aircraft systems power needs in the electrical form via shaft-driven generators. The conventional aircraft pneumatic bleed system design results in engine performance that is less than ideal. Since the total aircraft level power requirements are reduced when the pneumatic bleed is removed, the engine operates more efficiently and burns less fuel. Thus, the fuel-efficient feature of MEA is expected to increase the growth of the more electric aircraft market.

The use of high-performance electric drives (HPED) in the MEA architecture can control an aircraft’s high electric loads and improve its performance. These innovations encourage the aviation industry to use MEA technology to meet the changing needs and demands of its customers.

Based on technology, the more electric aircraft segment is estimated to account for the largest share of the market in 2022. The increasing need to optimize aircraft performance has been a catalyst in boosting the growth of the more electric aircraft (MEA) segment. The hybrid-electric segment of the market is projected to grow at the highest CAGR, followed by fully electric aircraft over the forecast period. The growth of the market for hybrid electric technology across the globe can be attributed to the advantages offered by electric aircraft for airliners, including reduced consumption of fuel and lower maintenance.

By aircraft systems, airframe systems are expected to lead the market over the forecast period. The demand for less polluting, fuel-efficient, and high-performance propulsion systems for aircraft will be the primary driver of segment development. Based on application, the power distribution segment is estimated to account for the largest share of the market in 2022. The trend towards the development of electrical components is influencing the growth of the power distribution segment. Further, power conversion is one of the most important systems used in aircraft. Various equipment, such as inverters, transformer rectifier units, and transformers, are used on aircraft to provide power supply. Enhancement of operational efficiency and reduction in total aircraft system weight drive demand in the power conversion segment of the market.

In terms of sales, Europe leads the MEA market, followed by North America, Asia-Pacific, and LAMEA. Because of the country’s strong manufacturing and production infrastructure for more electric aircraft systems, the United States dominated the global more electric aircraft market share in 2019 and is projected to rise at a significant pace during the forecast period.

Based on region, the Asia Pacific region is expected to witness substantial growth during the forecast period. Countries in the Asia Pacific region are undergoing development and upgrading various capabilities in the field of aircraft electrification, which offers significant potential for the manufacturers of electric components. A rise in demand for low-cost carriers (LCCs) is one of the factors driving growth of the market in the Asia Pacific. With affordable air travel on the rise and relaxation in some government regulations, the Asia Pacific region is witnessing an increased procurement of LCCs. Additionally, increasing aerospace & defense expenditure and expansion in airline networks in emerging nations, such as India and China, are expected to drive the demand for aircraft electrification in the region.

The aircraft electrification market has been gaining traction over the past few years due to the presence of several established companies as well as startups. Some of the major players in the aircraft electrification market include Honeywell International Inc. (US), Safran (France), Thales Group (France), United Technologies Corporation (US), and GE Aviation (US), among others.

References and Resources also include:

http://www.boeing.com/features/2015/01/corp-hybrid-01-05-15.page

https://www.nasa.gov/centers/armstrong/features/sceptor.html

http://aviationweek.com/oshkosh-2016/airbus-e-fan-goes-hybrid

https://techcrunch.com/2018/07/08/the-electric-aircraft-is-taking-off/

https://now.northropgrumman.com/electric-airplanes-promise-cleaner-quieter-regional-air-travel/

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis