Norwegian oil and gas industry is heading into the Arctic, and its looking for Work clothing specifically tailored to Arctic conditions is hard to find. Industrial designers have now joined forces with researchers to create the perfect clothing concept. Wenaas is a leading supplier of work clothing to the oil and gas industry and aims to develop a clothing concept tailored both to the harsh Arctic weather conditions and the tasks that workers have to carry out.

U.S. military is increasingly concerned about Russian military build-up in Arctic and is acting to protect its own interests in Arctic. When Navy SEALs carry out dives in Arctic waters, or when rescue teams are diving under ice-covered rivers or ponds, the survival time even in the best wetsuits is very limited — as little as tens of minutes, and the experience can be extremely painful at best. Finding ways of extending that survival time without hampering mobility has been a priority for the U.S. Navy. US Navy, is working with researchers at MIT, is developing a new method for treating wetsuits that could extend the amount of time troops can spend in freezing water from minutes to hours.

Army posts in Siachen, Kargil and many more such places are above 12000 feet where they have to face extreme cold weather conditions. Siachen, Nathu La, Bumla, East Laddakh and Kargil are some of areas where negotiating with the prevailing weather condition without special clothing and equipments are impossible.

Army sources told One India that the government has to cough up Rs 600 to 800 crore on purchase of these special clothing and equipment so the process of Indigenisation was started by the government as both the government as well as the Army wanted to do this. The indeginisation programme taken up by the ministry and the Army has been able to save money to the tune of Rs 250 to 300 crore per Annam to the government exchequer.

Extreme Weather Requirements

Such clothes must not only provide effective protection against the wind and weather, but must also be durable, fire-proof, anti-static and designed to accommodate the use of hearing protection and communications equipment. This places great demands on both textiles and design.

“A major issue that emerged was that an ideal clothing concept would have to meet a set of contradictory requirements,” says says industrial designer and SINTEF researcher Ole Petter Næsgaard. “There is a clear need for protection against wind and moisture. The clothing must not only provide protection against a long series of risk factors, but must also be able to withstand rough handling,” he says.

“Moreover, workers move between tasks of vastly varying levels of intensity. Insulated thermal suits make the wearers sweat too easily when they’re very active. Those who have worked under these demanding weather conditions commonly find it difficult to regulate their temperature according to their needs,” explains Næsgaard, who is heading SINTEF’s contribution to the project.

Extreme weather clothing concept

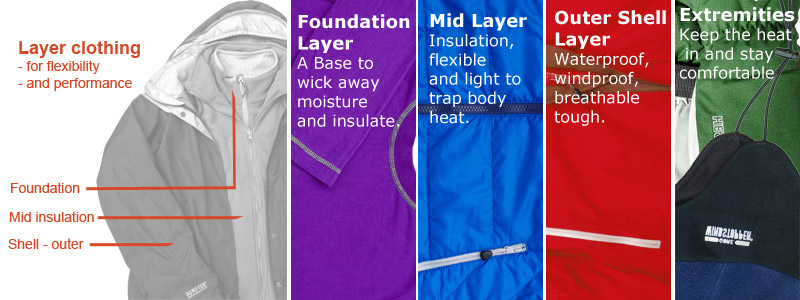

The “layer method” of dressing is more effective than a single bulky garment. Several layers are built up, each of which has its own part to contribute, insulating air is trapped between as well as within layers, flexibility is maintained as conditions change.

The layer next to the skin, this should be soft, comfortable and able to wick away perspiration quickly so leaving you feeling dry in spite of your exertions in the cold. Damp clothing in the cold can reduce the insulation significantly, so it is important to get sweat away from your skin and away from your clothes – breathability is of the utmost importance. To function most efficiently the foundation layer should be close fitting to the body. Modern foundation layer garments are generally made of synthetic material. In some cases the material is even treated so that it prevents the build up of bacteria that live in sweaty clothes and make them smell, especially important if you don’t have lots of changes of clothes or opportunity to wash them very often.

The gold standard of thermal underwear is merino wool, not a budget option but it really does deliver performance-wise. A soft and fine natural product, the wool of the merino sheep, very good at wicking sweat from the skin surface and naturally odor resistant.

The clothing concept is divided into several layers with the aim of making it easier to regulate insulation properties according to different weather conditions and work tasks. Priority is also given to practical functions, making it easy to use communications equipment and hearing protection devices. “A common problem today is that face masks and balaclavas are difficult to combine with hearing protection devices without the latter slipping and compromising noise protection,” explains Næsgaard. “Our solution is a specially-adapted balaclava made up of “zones” of fabrics of different thicknesses, each with its own function. This means that it works well both beneath a helmet and when wearing ear defenders,” he says.

As a base layer, researchers have selected something as unconventional as woollen underwear. “There is no fabric that can out-perform wool when it comes to providing thermal protection in wet conditions,” says Næsgaard. “Standard woollen underwear is worn by many rig workers today, and they’re very happy with its performance. Wool also meets the fireproofing standards required of all layers in contact with the skin,” he says.

However, when it comes to the intermediate layer, a lot of work has gone into developing a novel and more technical fabric. This is reminiscent of a medium-thick fleece, with a highly three-dimensional and airy structure enabling it to provide adequate ventilation when the wearer is active, and insulation when he or she is at rest. But even here, 50 per cent of the fabric is wool.

Major heat loss around the legs

The outer layer, or shell, has a waterproof and breathable membrane. A work clothing version of Gore-Tex is one of the textiles currently being tested. Major focus has been directed on the design to ensure that communications equipment is both easily accessible and at the same time not obstructive when the wearer is actively working.

The researchers have also spent a lot of time and energy looking into leg coverings.

“We’ve noted that keeping the leg area around and below the thighs warm is critical to a wearer’s sense of feeling warm enough,” says Øystein Wiggen, who is the physiologist responsible for testing the clothing concept. “At the same time it’s easy to lose a lot of heat from the legs because they’re less sensitive to cold,” he says.

The clothing concept also includes a new winter glove designed to conform to the natural curvature of the human hand. This enhances mobility and the wearer’s ability to grip objects in cold conditions. And in response to requests from workers, the glove has a woolen inner lining and built-in shock absorbance in the sections protecting the knuckles.

MIT Researchers develop New Materials

Michael Strano and Jacopo Buongiorno, two chemical engineering researchers at MIT, looked at the different strategies that various animals use to survive in these frigid waters, and found three types: air pockets trapped in fur or feathers, as with otters and penguins; internally generated heat, as with some animals and fish (including great white sharks, which, surprisingly, are warm-blooded); or a layer of insulating material that greatly slows heat loss from the body, as with seals’ and whales’ blubber.

In the end, after simulations and lab tests, they ended up with a combination of two of these — a blubber-like insulating material that also makes use of trapped pockets of gas, although in this case the gas is not air but a heavy inert gas, namely xenon or krypton.

The material that has become standard for wetsuits is neoprene, an inexpensive material that is a mix of synthetic rubber materials processed into a kind of foam, producing a closed-cell structure similar to styrofoam. Trapped within that structure, occupying more than two-thirds of the volume and accounting for half of the heat that gets transferred through it, are pockets of air.

Neoprene is full of little air pockets, or cells, that insulate a human in cold water. Strano and Buongiorno found that if the trapped air is replaced with xenon or krypton, the material’s insulating properties increase dramatically.They have discovered that if you fill the little air pockets with heavy, inert gases like argon or xenon, could improve survivability in water colder than 10 degrees Celsius, raising it from less than one hour to two or three hours.

In this work, we develop and demonstrate a strategy for drastically reducing the thermal conductivity of a flexible, closed-cell polychloroprene foam to 0.031 ± 0.002 W m−1 K−1, approaching values of an air gap (0.027 W m−1 K−1) for an extended period of time (>10 hours), within a material capable of textile processing. Ultra-insulating neoprene materials are synthesized using high-pressure processing at 243 kPa in a high-molecular-weight gas environment, such as Ar, Kr, or Xe.

The result, they say, is a material with the lowest heat transfer of any wetsuit ever made. “We set a world record for the world’s lowest thermal conductivity garment,” Strano says — conductivity almost as low as air itself. “It’s like wearing a coat of air.”

The process they discovered works by simply placing the standard neoprene wetsuit inside a pressure tank autoclave no bigger than a beer keg, filled with a heavy inert gas, for about a day. The treatment then lasts for about 20 hours, far longer than anyone would spend on a dive, explains Buongiorno, who is an avid wetsuit user himself. (He competed in a triathlon just last week.) The process could also be done in advance, with the wetsuit placed in a sealed bag to be opened just before use, he says.

One next step in their research is to look at ways of making a long-term, stable version of a xenon-infused neoprene, perhaps by bonding a protective layer over it, they say. In the meantime, the team is also looking for opportunities to treat the neoprene garments of interested users so that they can collect performance data.

“Our process is unique in that it modifies an existing wetsuit, making it demonstrably more insulating. So far, there are no tradeoffs with respect to comfort, flexibility, dexterity, etc. So the technology appears promising,” Strano told Defense One over email.

“The next phase of our research will examine the human factor for this technology,” he said. “We’ve demonstrated a record low in thermal conductivity for neoprene, an important advance for sure. But the next step is to conduct field trials,” meaning it’s time to collect more detailed measurements about how well the suit works on humans

Aerogel

Aerogels is an ultralight material, with 95-99% of it consisting of air or other gas, making them the lightest known solids and a standout amongst the most effective insulation materials. A profoundly permeable structure with low density forms a barrier, shutting out uncomfortable cold or warmth.

PrimaLoft Gold Insulation Aerogel, that is designed to give comfort in extraordinary weather conditions as it ensures against freezing temperatures, and heat. This is made conceivable through little air chambers that form a warm barricade that locks out the inconvenience of punishing temperatures. Integrated into shoes and gloves, PrimaLoft Gold Insulation Aerogel optimally performs, even under strain,” the company says.

“While lofted insulations can lose their elite performance under sustained compression, PrimaLoft Gold Insulation Aerogel gives phenomenal execution even when compressed by the movement of the hands and feet, retaining 98% thermal performance. This is particularly key for footwear, where each additional millimeter determines optimal fit and comfort.”

Research facility tests have demonstrated that insoles with PrimaLoft Gold Insulation Aerogel keep the foot warmer by 14°C in extreme cold (- 78°C) and 10°C cooler in high heat (60°C) than previous PrimaLoft footwear insulation. The tough PrimaLoft Gold Insulation Aerogel is additionally very fleaxable, waterproof and greatly lightweight.

Oros Used Space Technology To Create The Warmest Jacket On Earth

“Aerogel is what NASA uses to insulate the space shuttles, Mars rovers and other things in space,” Michael Markesbery says. “Space is negative 4550° F. This insulation is surviving the best torture test in the universe, but it isn’t being used in apparel.” Markesbery and Venna plan to disrupt the outdoor and performance apparel industry with Oros’ exclusive Solarcore insulation, the brand name for the company’s use of NASA’s aerogel material on which it has filed several patents.

Markesbery working alongside Venna found out why nobody had used aerogel in clothing. In its natural state aerogel is brittle and shatters when poked. “Our passion project for our senior year became figuring out how to make this amazing insulating material flexible and durable enough for apparel,” he explains. “We discovered how to take small particles of aerogel and use those particles to create a composite that can be put into fabric with minimal thickness and maintain 97% of its thermal performance. That is called Solarcore and it goes into all of our gear today,” Markesbery continues.

Markesbery breaks down the advantages of Oros’ technical superiority to goose down, and other insulating materials, scientifically:

- It passes the test – Solarcore has been laboratory-tested using ASTM C518 protocol against 250 insulating materials and to date, Markesbery says, “We haven’t found one yet that beats it.”

- No bulk – Trapping air is what makes every other insulation work and that creates volume, what the industry calls loft. The more loft or more air trapped, the more insulation provided. “So the more air you funnel in, the puffier and puffier your jacket becomes. You end up looking like the Michelin Man,” he explains.

- Breathability – On the flip side of staying warm, is what happens when you heat up inside your jacket, which is particularly problematic for performance wear and those engaged in outdoor activities. Oros has a fix for that. Solarcore doesn’t require super-dense fabric, like down does, to keep the insulation in.

Markesbery explains that most insulating materials, including Solarcore, goose down and other synthetics, are highly breathable, but the problem is the fabrics that are used to wrap around the insulation. “Down-proof fabric that keeps feathers from poking through are so tightly interwoven that they have constricted airflow,” he explains. “We have none of those limitations. We can put the most breathable fabrics around our insulation. The inner liner of our garments is sports mesh which is as breathable as it gets.”

“The Orion Parka has been taken to the summit of mountains in Nepal and back with only a t-shirt underneath,” Markesbery says, adding that a group of German trekkers braved -40° weather in the Siberian tundra going 60 miles an hour on snowmobiles. “It is the warmest jacket in the world,” he exclaims.

References and Resources also include:

https://www.sciencedaily.com/releases/2016/03/160308085933.htm

http://news.mit.edu/2018/artificial-blubber-protects-divers-frigid-water-0619

https://pciaw.org/industry-news/primaloft-brings-aeronautical-to-outerwear/