The wearing of body armour provide troops an unparalleled advantage on the battlefield, improving survivability and reducing casualtiesis. It has also been very effective in reducing injuries and fatalities within the police force and correctional services.

Body armor for soldiers is designed to protect them from a variety of ballistic threats, including bullets and shrapnel. It typically consists of a combination of hard and soft armor plates, which work together to provide a high level of protection. The hard plates are typically made of ceramic or polyethylene, which are able to stop high-velocity rounds. The soft armor is usually made of aramid fibers such as Kevlar, which is able to stop lower velocity rounds. The armor is often worn in a vest or plate carrier, which is worn over the soldier’s clothing and can be adjusted for a proper fit.

Armor requirements

There are several different types of threats that soldier’s body armor is designed to protect against, including:

- Ballistic threats: This includes bullets and shrapnel. Body armor is typically rated to protect against specific types and caliber of bullets, such as small arms fire (rifle rounds) and fragmentation. The threats to armor are small arms ammunition that range from 9 mm hand-gun bullets to 7.62 mm hard-cored, armour-piercing rounds. It is important to note that it is the core of the bullet that controls its penetration behaviour, not the calibre. The hardness of the core materials and the sharpness of the nose (blunt, ogival, or conical) will also affect the bullet’s penetration capability. The effectiveness of each of these small arms rounds is determined best by Kinetic Energy Density (KED) value based upon core dimensions, rather than calibre. This is the kinetic energy of the core, divided by the contact area projected onto the target.

- Stab threats: Some body armor also includes a stab-resistant layer to protect against knives and other sharp objects.

- Blast threats: In addition to ballistic and stab threats, some body armor also includes a layer to protect against the effects of explosions, such as shrapnel and concussive force.

- Environmental threats: The body armor also protects the wearer from extreme weather conditions, such as heat and cold.

- Chemical and Biological threats: Some body armors have special layers that can protect against chemical and biological warfare agents.

By definition, a ballistic impact is a dynamic event and is usually completed within 50 – 200ms. It is not too surprising, therefore, that effective, resistive responses by an armoured structure, including the armour material itself, need to occur within this timeframe. Futhermore, with strain rates of up to 10 exp5/ s, any material whose elastic and/or plastic behaviour is time-dependent will also respond differently under ballistic impact conditions. The flow strength and tensile modulii of polymeric materials like the UHMWPE and aramid fibres are particularly sensitive to strain rate.

The perceived threat spectrum, as specified by the User, will continue to be the dominant factor in determing the overall weight of a body armour system. All bullet-resistant, protective apparel is designed to arrest an attacking projectile without serious insult to the human body. This is achieved by various means and through the use of various conventional materials, depending upon the perceived threat.

For hand gun bullets it is common practice to use a pack of layered fabrics, loosely held or stitched together to form a comfortable wrap around the torso. For knife and spike attack, additional, or different, packs are used which contain various “stiffer” materials like laminated fabrics, or metallic elements. For high-velocity rifle rounds, including armourpiercing (AP) ammunition, a hard armour plate (HAP) is commonly added to the front of the system to work in conjunction with the soft armour pack and prevent perforation and serious blunt trauma.

Armor system trade-offs

This protection comes at a price, however. U.S. ground troops today carry an average of 27 pounds of personal protective equipment (body armor and helmet). This weight comes on top of an already heavy burden consisting of a weapon, ammunition, water, batteries, and other gear. Surveys from recent wars have found dismounted ground combat troops carrying 90 to 140 pounds or more in combat. Heavy loads reduce mobility, increase fatigue, and reduce mission performance.

The Army’s current torso body armor system (Improved Outer Tactical Vest with ESAPI plates) weighs approximately 30–35 pounds, depending on size and specific configuration. This weight has the immediate effect of reducing soldier mobility and performance.

Operational requirements will continue to dictate which particular system is employed in the field, and the choice is now very wide. Body armor provides increasingly advanced protection, but heavy, bulky, and hot armor may affect soldier performance.

It has the immediate effect of hampering soldier mobility by adding weight, limiting joint mobility, and restricting movement in tight windows, doorways, and vehicles not designed for the bulk of modern armor.

While fighting in in close-quarter combat, infantry soldiers have to maneuver, take cover, quickly assist fellow soldiers and in some instances, jump from rocks or building to avoid lethal enemy fire. Additionally, armor traps heat, increasing soldier thermal load, a particular concern in hot environments.

By contributing to overall soldier load, armor also restricts visibility, reduces situational awareness, and delays response times. Heavy loads decrease situational awareness by tilting the head at a downward angle and increasing the amount of weight that has to be controlled when a soldier stops quickly. In controlled experiments, loads also have been demonstrated to adversely affect shooting response times, increasing the time it took soldiers to fire accurately by 0.1 second relative to unloaded conditions. Cumulatively, armor’s weight, bulk, and thermal load increases soldier fatigue and reduces physical and cognitive performance.

Additionally, over the course of a mission, the weight has a cumulative effect of increasing soldier fatigue, further reducing physical and cognitive performance. In hot climates, the increased thermal load that comes from body armor trapping heat on the torso can also severely negatively affect soldier performance and risk heat injury.

The perceived threat spectrum, as specified by the User, will continue to be the dominant factor in determing the overall weight of a body armour system.

Body Armor doesn’t protect against all threats

It’s important to note that no body armor can protect against all types of threats and that body armor can only protect against certain types of bullets from certain firearms, at certain velocities, and from certain distances. There are also new and developing threats, such as Armor-piercing bullets, that can defeat some body armor.

Even with their weight, current body armor systems leave several vulnerable areas exposed to high-velocity ballistic (e.g., rifle) threats. Existing body armor provides effective ballistic protection to the torso but does not fully protect the head, face, neck, groin, upper side, or extremities. Soft armor protects soldiers from explosive fragments and pistol rounds, but not high-velocity rifle rounds. Soldiers have no protection from high-velocity ballistic injuries to the face.

While today’s body armor, which consists of hard armor (ceramic plates) and flexible soft armor, protects against explosive fragments, it is not designed to protect soldiers from the pressure wave itself that comes from blast explosions. Even wearing a helmet, the head is largely exposed to harmful blast waves that can damage the brain. As a result, soldiers remain exposed to blast overpressure that can cause insidious and debilitating brain injury.

Redesigned helmets, especially modular helmets with removable full-face shields, could be even more effective in protecting soldiers from harmful blasts, potentially reducing blast pressure in the brain by up to 80 percent compared to the current helmet.

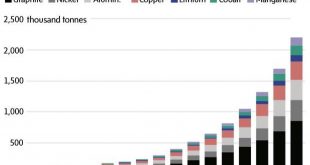

Advanced Material developments

The specific type of armor worn will depend on the mission and the threat level. Some armor may be more heavy and restrictive than others, but provide a higher level of protection.

Advanced armor can use a variety of materials for shock absorption, including:

- Aramid fibers: such as Kevlar, are a type of synthetic polymer that is lightweight and has excellent energy absorption properties, making it a popular choice for body armor.

- Polyethylene: is a type of plastic that is also lightweight and has good energy absorption properties. It is often used in combination with aramid fibers to create body armor that is both lightweight and protective.

- Ceramic: plates made of ceramic materials such as alumina or silicon carbide, can provide excellent protection against high-velocity rounds, but they can be brittle and can fracture upon impact.

- Metal composites: such as aluminum oxide, can also be used to absorb the impact energy of a projectile.

- Hybrid materials: some advanced armors use hybrid materials that combine the properties of different materials to provide the best possible protection.

- Gel-based materials: some armors use special gel-based materials that can absorb impact energy and reduce the transmission of shock to the wearer.

It’s important to note that, these materials are often used in combination to create body armor that is both lightweight and protective. The specific material and construction of the armor will depend on the level of protection needed and the intended use (e.g. combat, training, etc.).

Body armor for soldiers is typically made of a combination of materials, including ceramic plates, aramid fibers (such as Kevlar), and polyethylene. Ceramic plates provide protection against high-velocity rounds, while aramid fibers and polyethylene offer protection against lower velocity rounds. The specific materials used and the construction of the armor will depend on the level of protection needed and the intended use (e.g. combat, training, etc.).

In addition to traditional body armors, there are also advanced armor systems like E-type body armor, which is made of layers of ceramic, polyethylene and aramid fibers and are tested to stop multiple hits of rifle rounds.

Researchers are engaged in development on better materials that could dramatically decrease weight while maintaining or increasing the level of protection as well as improve levels of comfort and fit. Because reduced weight would lighten the soldier’s load and increase performance, soldier survivability as a whole could improve significantly. Cost reduction is also a commercial driver, especially when standard body armour systems can be priced as high as several thousand dollars per set. Each of these challenging requirements are being met through development of new materials, innovative designs and lighter weight systems.

For body armour applications, three main grades have established themselves in the market place: high-purity aluminas, silicon carbides and boron carbides, increasing in ballistic merit rating, and price, in that ascending order. For most ballistic applications, boron carbide remains the ultimate armour material of choice as it is one of the hardest ceramic materials, falling just short of diamond and cubic boron nitride, and, because of its low density (~2,520 kg m3), it has a very attractive set of specific properties for body armour systems but it does have several natural drawbacks: cost of manufacture and, like all ceramics, shapeability.

Improving the ballistic performance of ceramics through the addition of reinforcing particles has always attracted the attention of researchers. For example, in a very recent study Alexander et al., looked at the effects of adding graphene nano platelets (GNP) to boron carbide matrices. The addition of 2% (by volume) of GNP was found to improve bulk density by acting as a sintering aid but apart from a small increase in fracture toughness levels, there was a reported decrease in flexural strength e a common finding when working towards a ceramic matrix composite.

Commercially available blends are available through Paxis (in Israel) and Precision Ceramics (in UK), to name but two. It is believed that such companies use a 40/60 blend of B4C/SiC to obtain optimum ballistic performance at an affordable price.

Armour solutions, based upon Ultra High Molecular Weight Polyethylene (UHMWPE), have now become the systems of choice for many police and miltary users, replacing the aramid-based solutions that have dominated the market for the past three decades or so. These fibers have high breaking strength per unit cross section area—about 15 times stronger than steel—but are flexible like fabrics. Like US Army’s current combat helmet is made of ultrahigh molecular weight polyethylene or UHMWPE fibers-based composites.

US ARL laboratoties have discovered new materials PUUs, polyurethanes, and similar elastomers that exhibit dynamic strengthening in high-rate deformations that limit deformations of the helmet under impact would make for better combat helmets. Scientists say their discovery on bulk elastomers can help design matrix materials for composites for the future generation of U. S. Army combat helmets.

One of the newest types of body armor, though, is both flexible and lightweight is liquid armor.Liquid armour is a material that hardens very quickly when struck by a projectile at speed, in order to absorb the impact energy. The two primary types of liquid body armor currently in development both start with a foundation of DuPont Kevlar, commonly used in bulletproof vests. BAE Systems is alsolooking to apply the technology to emerging requirements.

One of the most noteworthy and significant advances in body armour materials in the past 20 years has been the evolution, and extended development, of the Ultra-High Molecular Weight PolyEthylene (UHMWPE) fibres and fabrics. In a laminated form, they are now able to arrest a mild-steel-cored, 7.62 mm, highvelocity bullet at point blank range – a feat that few thought was ever possible.

While scientists at the U.S. Army’s Army Research Lab were researching ways to make tougher, more lightweight armor, they found the outer coating of pearls made for exceptionally tough armored protection. The coating, built with nacre or “mother of pearl,” is made from mollusks out of calcium carbonate. Calcium carbonate isn’t particularly strong, but can be made considerably more resistant to impact by arranging it into a structure that resembles LEGO-like interlocking bricks.

The new armor technology takes ultrahigh molecular weight polyethylene, or UHMWPE, and adds silica nanoparticles for strength. The result, the Army Research Lab says, is a “lightweight plastic that is 14 times stronger and eight times lighter (less dense) than steel and ideal for absorbing the impact of bullets and other projectiles.” Kevlar, used in many types of armors, is five times stronger than steel.

“The material is stiff, strong, and tough,” Dr. Shenqiang Ren, project lead and professor in the Department of Mechanical and Aerospace Engineering at University at Buffalo, told the Army Research Laboratory Public Affairs. “It could be applicable to vests, helmets, and other types of body armor, as well as protective armor for ships, helicopters and other vehicles.” A further benefit is that the armor has high thermal conductivity, allowing it to dissipate heat from kinetic energy faster and absorb transferred energy from bullets and other projectiles.

The new UHMWPE armor is also easier to cast or mold into complex shapes, says Dr. Evan Runnerstrom, program manager, materials design, Army Research Office. “In contrast to steel or ceramic armor,” he says, “UHMWPE could also be easier to cast or mold into complex shapes, providing versatile protection for Soldiers, vehicles, and other Army assets.”

Similarly, D3O has developed a number of armour products for defence from soft, flexible materials with high shock absorbing properties. In its raw form, the company’s material’s molecules flow freely, allowing it to be soft and flexible, but on impact, lock together to dissipate impact energy and reduce transmitted force.

The U.S. Army is developing new materials that can withstand the harshest environmental condition on the battlefield—high-energy kinetic combat. A multipronged research effort at the Army Research Laboratory aims at creating exotic materials that would protect warfighters and their equipment from new kinds of weaponry that are appearing, and may appear, in future tactical combat. The future battlefield may be harsher from both enemy action and climate. Near-peer adversaries are pushing their own research into deadlier weapon systems against which U.S. forces must defend. Climate changes are leading to hotter desert environments while opening up arctic regions to competition—and potential conflict in the harshest of cold conditions.

Future Army Vehicles Could See An Improvement In Structural Materials

Two of the major limitations of body armor today – the lack of greater body area coverage and the weight burden of armor – stem directly from the weight of hard (ceramic) armor. Armor used to protect soldiers and vehicles has traditionally been comprised of ceramics, metals, or lightweight fiber-reinforced composites, which are typically based on stiffness (the resistance of a material against deformation) and toughness (the ability to absorb energy and plastically deform prior to fracture).

Materials used for a Soldier’s personal protection gear may be tough enough for vehicles too, according to a new Army study. Findings, released April 2020 in the journal Polymer, show that polymers filled with carbon nanotubes could potentially improve how unmanned vehicles dissipate energy. A team led by the U.S. Army’s Combat Capabilities Development Command’s Army Research Laboratory is conducting theoretical research through computer modeling.

Researchers said polyurethanes are versatile materials used in a broad variety of applications, including coatings, foams and solid elastomers. As film adhesives, for example, they are commonly used as bonding agents between layers of glass and as polymer back layers in the transparent glass or plastic composites such as vision blocks on side windows used in the tactical vehicles. In particular, high-performance segmented PUU polymers exhibit versatile physical and mechanical properties. In this research, the team used computer modeling to look into the nature of the materials. Sliozberg said hierarchical composites are a promising area of research for the Army vehicles as they are less susceptible to corrosion, leading to early component death. “In contrast to traditional thermoset composites performance poly(urethaneurea) elastomers are far less brittle and they offer unparalleled control over material architecture,” Sliozberg said. “Carbon nanotube/polymer composites have desirable electrical and thermal characteristics that exhibits behaviors superior to conventional fiber materials.”

Sliozberg said they need to have deeper understanding of the nature of molecular level interactions in these materials in order to enhance the maximum stress levels it can withstand and tailor energy dissipation mechanisms. Chemical modification of nanofillers is nontrivial and typically diminish their properties by changing their structure and chemistry. For example, the Young modulus could be lower, she explained. This team’s results strongly indicate the effectiveness of incorporation of aligned carbon nanotubes for microstructure optimization of hierarchical PUU polymers in the matrix as well as at the interface without any filler surface modification, Sliozberg said. “It shows that the presence of high affinity of poly(urethane-urea) to carbon nanotubes would lead to a novel green synthesis pathway without the need of any surface functionalization of nanotubes for fabrication of carbon nanotube reinforced poly(urethane-urea) nanocomposites hierarchical composites,” she said.

Future Army vehicles could see an improvement in their structural materials since they are less susceptible to corrosion, lightweight and have higher electrical conductivity than traditional elastomers. The materials also show great potential to protect vehicles against static build-up and discharge and lightning strikes. “Certain military vehicles such as Army helicopters must withstand intense vibration and fatigue and the conductive nature of these materials could lead to an unprecedented level of multifunctionality with potential in real-time structural health monitoring through embedded strain sensing and damage monitoring that will lead to safely and accurately assessing the remaining life in vehicle components,” Sliozberg said. Collaborators at Drexel University are furthering the research by investigating the potential uses of PUU polymers with carbon nanotubes as filament materials for 3-D printing. The laboratory is not currently conducting these studies on any vehicles. Researchers plan to collaborate with other Army teams for testing in the near future.

Armor systems

Modular systems, as represented by the Modular Combat Body Armour System (MCBAS) developed for the Australian military, have a fixed shape and a soft vest that provides near maximum coverage as these are very functional when carrying out patrolling duties , they are also popular with the police services since they offer comprehensive coverage against handgun rounds and offer the ability to be upgraded for protection against high-velocity rifle rounds, by using a supplementary HAP in front of the vest. Tiered systems, on the other hand, utilise smaller vests that differ in size depending upon the operational requirements.

Global suppliers of body armour systems, like Morgan Defence Systems, offer a very comprehensive range of both stand-alone and lightweight, tiered systems. Of greatest significance, however, are the Stacked systems these are totally new and would not have been possible had it not been for the rapid development of the UHMWPE laminates. Tencate Advanced Armour launched such a system at Milipol, France, in November 2017 , these utilise two, stackable, HAPs the first is UHMWPE based and offers protection against both lead-filled and mild-steel-cored ammunition; the second is a ceramic-rich HAP which, in combination with the first HAP, offers protection against the high-velocity armour-piercing rounds. It also appears that the Canadian DND have acquired a similar stacked system from PRE Labs.

The advent of stacked systems, introduces yet another interface within a body armour system, and a final word of caution is required. Controlling the quality, and magnitude, of interfaces, not only between the layers within a soft armour pack, and the gap between soft vest and the HAP, but now also between HAP1 and HAP2, is very crucial in guaranteeing the reproducible quality and ballistic performance of a body armour system it is highly ecommended

Poly(urethane urea) elastomers for combat helmets

Earlier, Army Research Laboratory’s Dr. Alex Hsieh, along with Prof. Keith A. Nelson, Dr. David Veysset and Dr. Steven Kooi, from the Army’s Institute for Soldier Nanotechnology at MIT, discovered that when targets made of poly(urethane urea) elastomers or PUUs are impacted at very high speed by micro-particles made of silica, the PUU target shows hyperelastic behavior. That is, they become extremely stiff when deformed at strain rates on the order of 108/s which means roughly that the material of the target deforms to half of its original thickness in an extremely short time equal to one second divided by hundred millions. PUUs also quickly return to their original shape after the impact, said Hsieh.

Hsieh said the team focused on polymers, which are made up of a very large number of small molecular units that are strung together to form very long chains, which can be well organized or randomly packed. Specifically, polymeric materials that are strong like impact-resistant safety glasses or flexible like rubbers.

Elastomers are a class of human made rubbers, which can be synthesized from a broad range of polymer chemistries. “They generally have low Young’s modulus which means low resistance to elastic deformation under loading at ambient conditions, and higher failure strain the capability to sustain significantly greater amount of strain before failure than most of the plastic materials,” he explained.

Elastomeric polymers are promising materials for ballistic impact protection both on the macroscale (for example, in armour panels) and on the microscale, for example as protective coatings for helicopter rotor blades and in powder blasting. Among elastomer candidates for enhanced ballistic protection, polyureas, polyurethanes, and PUUs have recently gained interest owing to their versatile dynamic response. Because of the thermodynamic incompatibility between building blocks, these polymers present a complex morphology with domains having different degrees of microphase separation between hard and soft segments. Recent studies have indicated that the extent of phase–mixing strongly affects the segmental dynamics and the strain–rate hardening characteristics of PUUs.

“This is very exciting.” said Dr. Hsieh “Seeing is believing. New understanding from these research discoveries — the essence of hyperelastic phenomenon in bulk elastomers particularly at the moment of target/impulse interaction strongly points out to be a plausible pathway key to manipulating failure physics and towards a new design paradigm for robust materials.”

However, from the point of view of materials science, just these typical bulk metrics are not adequate to evaluate the speed with which the mobility of molecules in a polymer solid is changed in relation to deformation rate, as well as the tendency of modification of their respective physical state as part of the dynamic deformation. The question remains, do elastomers get modified from rubber-like to glass-like while being deformed at increasingly higher rates.

For further verification of the molecular effect, the Researchers performed elaborate research on PUUs together with a glassy polycarbonate. Whereas the polycarbonate has high ballistic strength and fracture toughness, the PUUs (in spite of their respective composition) were found to have higher dynamic stiffening upon being impacted at strain rates of 108/s. In addition, Researchers can optimize the resistance to micro-particle penetration, that is, approximately 50% decrease in the average maximum penetration depth was accomplished by just altering the molecular composition of the PUUs.

China Develops Bullet-Proof, Fire-Proof Fiber For Military Equipment

China has developed a strong, light fiber nick named “golden silk” that is resistant to heat and corrosion for use in fire-proof and bullet-proof military equipment. “The material can be used to make body armor and other protective components for precision instruments or military hardware,” military analysts were quoted as saying by Global Times on Sunday.

After 16 years of development, state-owned oil giant Sinopec announced it had developed a type of para-aramid fiber, Beijing-based newspaper Science and Technology Daily reported on Saturday. Kevlar is a similar type of material. The material is a strategic asset to the country and the military, which has wide applications in both civilian and military fields, like the making of cables, optical fibers, frame materials and composite materials, the report said.

A standard application for “golden silk” is to make body armor, which weighs only 1.5 kilograms and is many times more efficient than a steel plate in taking and dispersing kinetic energy from bullets and shrapnel. With the fiber, body armor can even block rapid fire from a light machine gun, according to the report.

“The material can also be used in the manufacturing of vehicles, ships, aircraft and rocket, as it provides extra structural strength and resistance to harsh environments,” a military expert told Global Times. Sinopec said in a statement that China used to trail foreign countries in making high-performance fibers, and related technologies were controlled by those countries as they kept inflating the price and banned supply in military use. With the domestically developed technology, the fiber now becomes affordable and is available to the Chinese military and arms industry, the expert said.

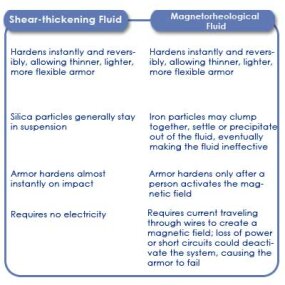

Liquid armour to become a future choice for protecting soldiers

BAE Systems and Helios Global Technologies have signed a Memorandum of Understanding (MoU) to further develop liquid armour technology. Liquid armour is a material that hardens very quickly when struck by a projectile at speed, in order to absorb the impact energy. The liquid is actually a shear-thickening fluid (STF), which behaves like a solid when it encounters mechanical stress or shear

When a projectile impacts the material at speed, it hardens very quickly and absorbs the impact energy. When combined with Kevlar, the reduced flow of the fluids in the liquid armour restricts the motion of the fabric yarns. This means an increase in area over which the impact energy is dispersed. The material is therefore far less likely to distort than standard body armour, which generally bends inwards when a bullet strikes, preventing death, but causing considerable pain.

The fluid used in body armor is made of silica particles suspended in polyethylene glycol. Silica is a component of sand and quartz, and polyethylene glycol is a polymer commonly used in laxatives and lubricants. The silica particles are only a few nanometers in diameter, so many reports describe this fluid as a form of nanotechnology.

Liquid armour is a material that offers increased protection with reduced mass, wider area coverage, greater manoeuvrability and easy integration with other systems. In studies when combined, the two materials offer superior freedom of motion and a reduction in overall thickness of up to 45 per cent.

In laboratory tests, STF-treated Kevlar is as flexible as plain, or neat, Kevlar. The difference is that it’s stronger, so armor using STF requires fewer layers of material. Four layers of STF-treated Kevlar can dissipate the same amount of energy as 14 layers of neat Kevlar. In addition, STF-treated fibers don’t stretch as far on impact as ordinary fibers, meaning that bullets don’t penetrate as deeply into the armor or a person’s tissue underneath. The researchers theorize that this is because it takes more energy for the bullet to stretch the STF-treated fibers.

Magnetorheological Fluid

The other fluid that can reinforce Kevlar armor is magnetorheological (MR) fluid. MR fluids are oils that are filled with iron particles. Often, surfactants surround the particles to protect them and help keep them suspended within the fluid. Typically, the iron particles comprise between 20 and 40 percent of the fluid’s volume.

The particles are tiny, measuring between 3 and 10 microns. However, they have a powerful effect on the fluid’s consistency. When exposed to a magnetic field, the particles line up, thickening the fluid dramatically. The term “magnetorheological” comes from this effect. Rheology is a branch of mechanics that focuses on the relationship between force and the way a material changes shape. The force of magnetism can change both the shape and the viscosity of MR fluids.

Researchers have proposed creating tiny circuits running throughout the armor. Without current flowing through the wires, the armor would remain soft and flexible. But at the flip of the switch, electrons would begin to move through the circuits, creating a magnetic field in the process. This field would cause the armor to stiffen and harden instantly. Flipping the switch back to the off position would stop the current, and the armor would become flexible again.

Modular Soldier Protection System Torso and Extremity Protection (SPS TEP) Ballistic Battle Belt (B3)

The US military’s next iteration of body armour will focus on reducing weight further and increasing scalability to allow the wearer to adjust his equipment depending on the threat level and mission at hand.

Product Manager Soldier Protective Equipment of the Program Executive Office Soldier, Fort Belvoir, VA 22060 is seeking information from potential industry partners to support the Army’s next generation protection system called Soldier Protection System Torso and Extremity Protection (SPS TEP) Ballistic Battle Belt (B3).

An operational need exists to provide the Soldier a ballistic personal protective system that allows the user to tailor his/her loads for mission-specific operations, thereby increasing survivability and mobility. The goal of SPS TEP is to provide the Soldiers with modular and scalable/mission-tailorable protection to reduce weight and increase mobility while optimizing protection. The SPS TEP is a Government design that consists of four (4) components, the Modular Scalable Vest, the Ballistic Combat Shirt, the Blast Pelvic Protector, and the B3.

The B3 is a standalone component worn over the Army Combat Uniform and is designed to provide fragmentation protection and to distribute the Soldiers combat load between the shoulders and waist/hips. The B3 has three (3) sizes: Small (S), Medium (M), and Large (L).

The U.S. Army Is Working on 3D Printed Body Armor

New research into 3D printing technology could someday lead to the U.S. military 3D printing body armor for soldiers. The technology, which looks to abalone shells for inspiration, could allow units to print armor themselves, foregoing a cumbersome supply process. Researchers at the Army Research Laboratory, according to The National Interest, are developing ways to 3D print ceramic materials.

ARL is pursuing a printing approach that creates high density ceramics—a key requirement for body armor. Ceramics are more difficult to 3D print than plastics or metals, but they are also a key component of body armor designed to protect soldiers from bullets and shrapnel on the battlefield. ARL researchers are looking to the graded nature of an abalone shell—built up layer upon layer over time by the single-shell mollusk—for inspiration. The density of the ceramic material is meant to shatter incoming projectiles. The goal is to eventually field body armors that are tougher and lighter than existing ceramic body armor.

The ability to 3D print body armor would be a major advancement for the U.S. military. Instead of going through the cumbersome process of procuring hundreds of thousands of sets of armor for men and women of all heights and body types, the services could just take a soldier’s measurements and then use a printer to crank out the right fit.

No longer would the Pentagon get stuck with unused armor sizes (and almost certainly run short of other sizes), and units waiting for the supply chain to fulfill requests would be a thing of the past. New armor requests could be fulfilled in hours. Units in the field, thousands of miles away from supply depots in the U.S. could quickly fabricate armor themselves.

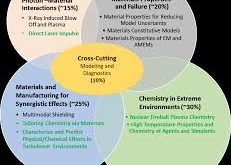

US Army Research Laboratory Researching tougher lightweight armor

The U.S. Army Combat Capabilities Development Command’s Army Research Laboratory (ARL) is focusing on extreme environment materials in three categories, explains Sikhanda Satapathy, Ph.D., collaborative alliance manager for Army Materials in Extreme Dynamic Environments (MEDE) Collaborative Research Alliance program at the ARL. The MEDE program includes a university consortium led by Johns Hopkins University. These categories—metals, ceramics and composites—offer a host of new possibilities for personal and vehicle armor. Ultimately, research conducted in any of the categories may cross domains and lead to advances in the others.

This research is driven both by specific applications and by the art of the possible, Satapathy offers. Many of the pursuits are goal-oriented, but the basic research probes new avenues of material development. The laboratory builds both applied and basic research goals around emerging and predicted threats, he notes. Its efforts are aided by industry and academia, along with resources available in national laboratories, particularly high-performance computing such as in the Defense Department’s High Performance Computing Modernization Program. And it is employing artificial intelligence and machine learning to help discover new materials.

Satapathy explains that the ARL is working on materials that can withstand the operating environment of military conditions—high pressure, high stress, high strain rate—as opposed to the more benign environment of the commercial sector. Global environmental changes are also affecting armor development. Satapathy points out that body armor must withstand the temperature extremes that soldiers will encounter, whether in the hot desert or the frigid arctic. This issue applies to vehicular armor as well, as some composites may lose their best properties at extreme temperatures, and metals can undergo property changes along with the existing temperature.

But the stresses brought on by the natural environment pale in comparison to those of the battlefield, Satapathy emphasizes. The high-pressure, high-strain conditions introduced by weaponry are not found in common material applications such as bridges and skyscrapers. High-velocity projectiles impacting on armor generate pressure exceeding the strength of ordinary materials by several times, he says.

One key characteristic that must play in any new protective materials is weight. The ARL is looking to lighten the load that soldiers carry, and it doesn’t want heavy armor weighing down ground and aerial vehicles, costing them mobility and fuel efficiency. So the new materials must be able to survive these extreme conditions at minimum weight, Satapathy emphasizes.

Within each of the three classes, the ARL has identified materials within their science base to build new substances. These efforts range from molecular scale to mesoscale and macroscale, Satapathy says. Exotic works study multiple time scales where the atoms and molecules operate in nanoseconds up to microseconds, where laminates operate.

In metal research, the ARL’s focus on weight comes to bear. The laboratory is working with magnesium, which is one of the lightest structural metals available. But it cannot compete with metals such as steel or aluminum because of lower strength and inherent failure mechanisms. The laboratory is identifying those failure mechanisms and working to ameliorate them, Satapathy says.

For example, a sheet of magnesium will shed a piece of material when it’s struck by a projectile, which doesn’t bode well for its use as armor. ARL researchers are striving to understand the metal’s characteristics that allow for this type of failure, and then they would redesign the material and its processing. Demonstrations have shown that different manufacturing processes can improve performance by at least 10 percent, he relates.

Another thrust is to create an entirely new alloy in which other elements are added without significantly changing the weight. This approach aims to prevent the material failure process—a piece blowing out the back. After finding an acceptable alloy, the laboratory still must determine how to process and manufacture the new material effectively, Satapathy says.

Some work focuses on making a magnesium alloy strong enough to avoid its failure pattern. Depending on the nature of this magnesium alloy, it might be combined with other conventional materials. He continues that what the laboratory is learning in its work with magnesium will be applicable to other metals research such as aluminum and steel.

For ceramics, the bulk of the laboratory’s research involves reducing the brittleness of this incredibly hard material. Its hardness is five times that of metals, but its tensile strength is about five times less than that of metals. Yet both hardness and high tensile strength are desirable. So, the laboratory is working in collaboration with Johns Hopkins and Rutgers University with boron carbide as a candidate ceramic material. Among its failure mechanisms is an amorphous shear tendency in which the crystal integrity of the material is lost. The ARL research team is looking at using molecular materials that strengthen the crystal structure.

One such approach is to dope the boron carbide with silicon, and the laboratory has found it reduces the amorphization problem. Unfortunately, the material’s strength also suffers, Satapathy says. So, researchers went back to the laboratory to look at another potential additive, titanium diboride, to add strength to the silicon-doped material. The next step would be to scale up production of this new material for larger samples. “We are developing the science, we are making new materials and also we are creating the next [generation scientific] workforce—people who will be solving our problems in the future,” he states.

In composites, the ARL is working with the University of Delaware, which is looking at a glass-epoxy composite. Again, these researchers are examining the material’s failure modes. These composites are built around fibers surrounded by matrix materials in layers. The scientists at Delaware are working on individual fibers with modeling at the molecular level, Satapathy reports. One of their findings is that coating the fiber chemically can prevent the failure of the fiber. Also, interface material between the fiber and the matrix material can improve bonding, increasing composite strength. This team has come up with a new chemistry by adding small amounts of different materials, he continues. With these combined advances, their composites are stronger. The ARL is working with industry on production processes that would permit larger pieces of composite material for testing.

New composites would be used in current applications such as helmets and body armor as well as in vehicles as protective structures, Satapathy offers. Ceramics would provide similar protection at a minimum weight, which would be especially useful for individual soldiers. Metals primarily would be protecting vehicles, particularly against improvised explosive devices (IEDs) and tank rounds. Soldiers must be protected against small arms and blast effects, while ground vehicles must be safe against IEDs and warheads. Their defense features different time and energy parameters, Satapathy notes. “You want to stop the threat with the lowest possible weight,” he states. This becomes especially vital as the force strives for greater mobility.

The research in these three areas is not limited to the specific disciplines. Combining different materials is atop the ARL’s list for materials research, Satapathy says. For soldier protection, the lab uses multiple materials, such as a ceramic plate backed by a composite panel. In this case, it is vital to understand the response of the system, he notes, and in many situations one type of material perfectly complements another. And these combinations can be varied to emphasize different strengths. If designers are striving for resistance as opposed to stiffness, a composite and a ceramic can be combined to achieve the optimum effect. “Each of these class of materials has its own advantages and capabilities to blunt or absorb the energy of a projectile,” Satapathy points out. “One could design an armor system taking advantage of these three types of materials.”

Threats are becoming more dangerous, with near peers and other adversaries advancing their weaponry. Satapathy allows that the ARL is working to defeat both upcoming threats and new ones that may lie over the horizon. “For some things, we have to start now. We cannot wait until those threats show up in the theater 10 years from today,” he warrants.

References and Resources also include:

https://www.afcea.org/content/army-researchers-look-few-tough-materials

International Defense Security & Technology Your trusted Source for News, Research and Analysis

International Defense Security & Technology Your trusted Source for News, Research and Analysis